1622

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

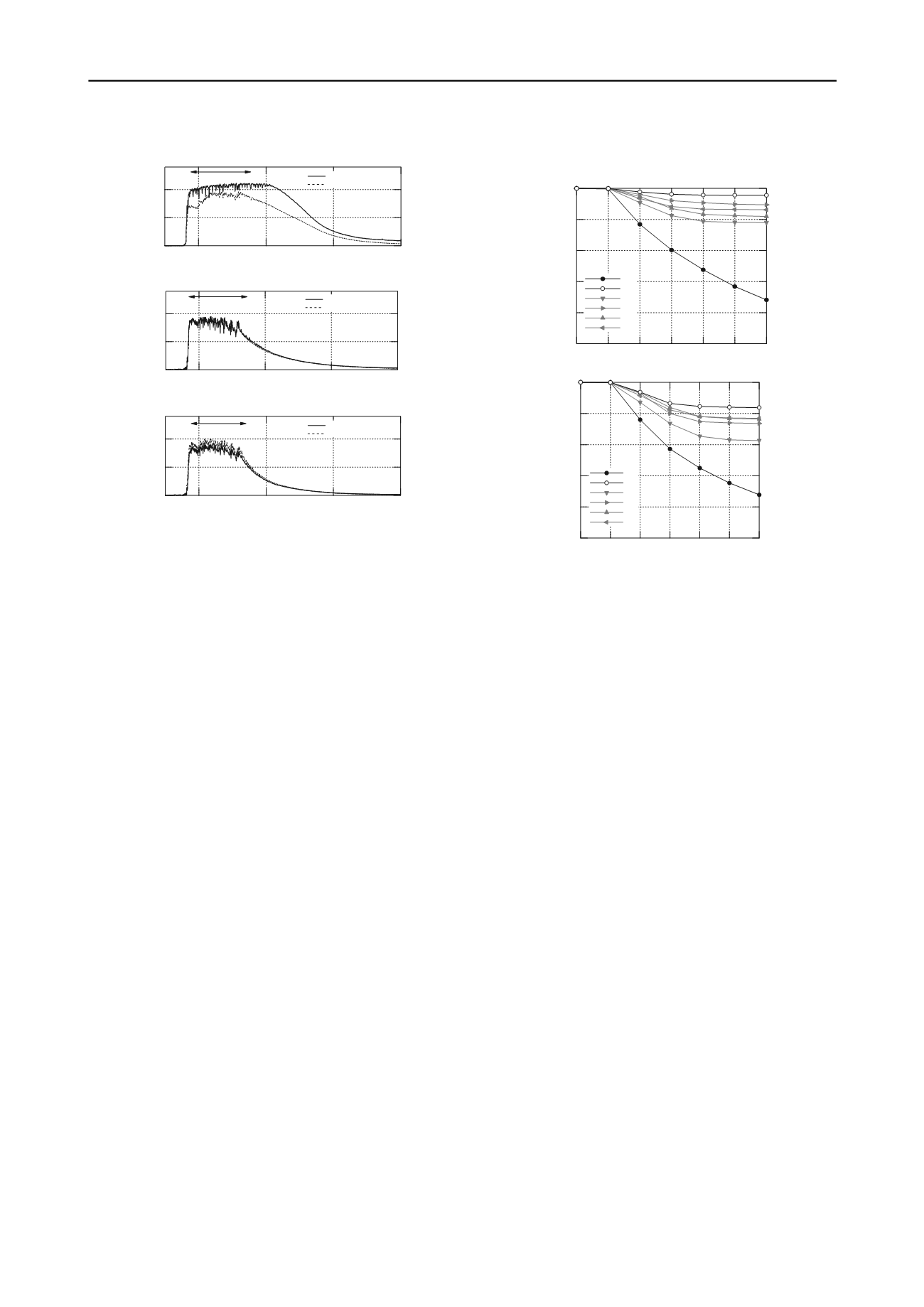

the principal motion. This behaviour indicated that the ground

was not fully liquefied although the excess pore water pressure

was generated. Similar tendency was observed in B2, the

floating-type improvement case, and the ground in B2 was not

also liquefied. It followed that the floating-type improvement as

well as the fixed-type one took effect, restricting excess pore

water pressure in a liquefiable sandy layer.

3.3.2

Ground settlement

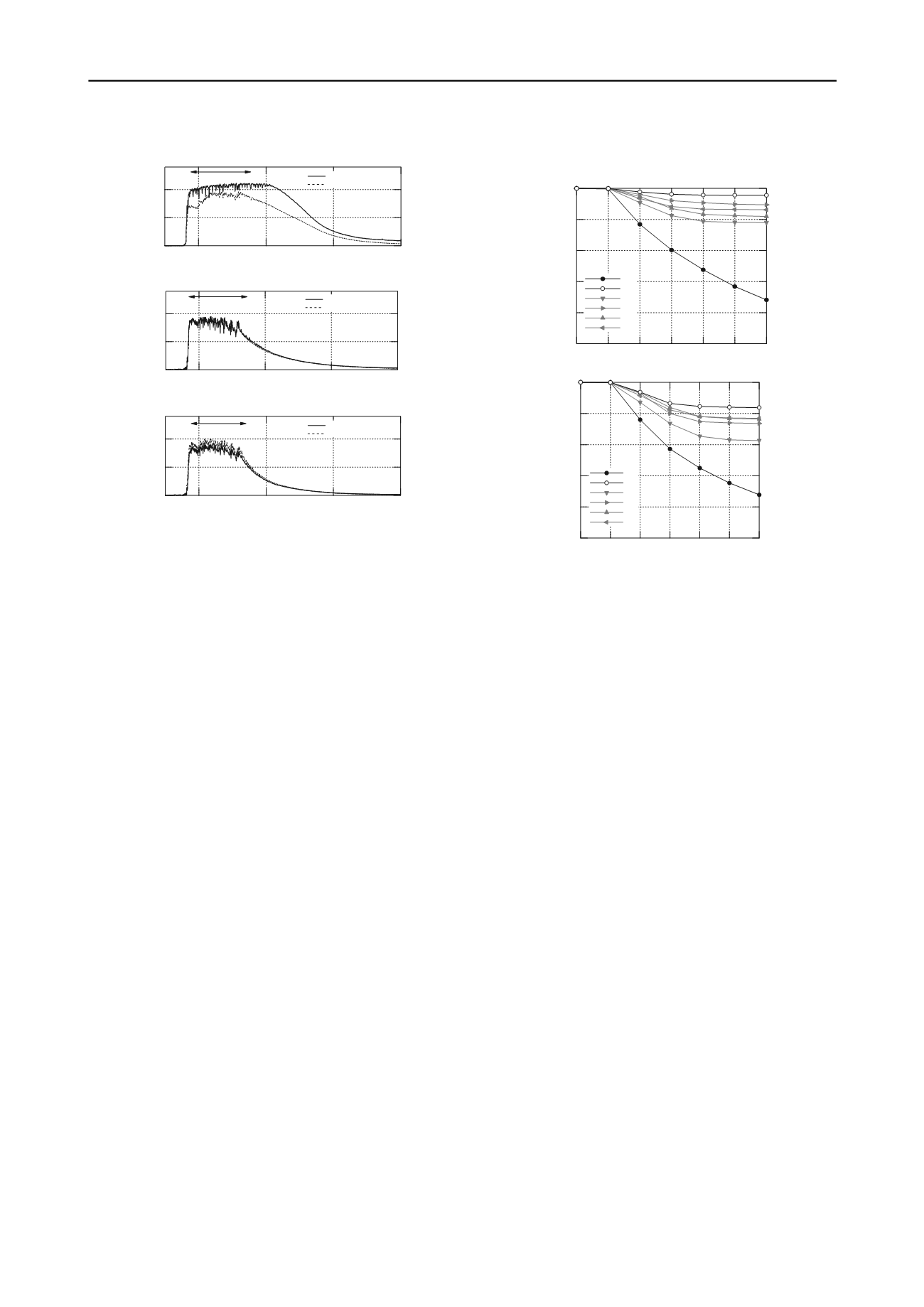

Figure 9 presents the cumulative ground settlement in Series B

in a proto-type scale. Each figure represents the settlement at

the top of the lattice-shaped mold and the ground surface inside

the grid, respectively. The horizontal axis shows the number of

stepwise shaking.

The ground settlement of B1, the unimprovement case,

reached 0.23 m in Step 2 and increased every step. The final

settlement was 0.72 m in Step 6. This large value was due to the

liquefaction of ground in every step. In the meanwhile, the

settlements of B2, the fixed-type improvement case, were 0.02

m at the top of the mold and 0.06 m at the ground surface. The

large settlement could not be found in the successive shaking

steps due to no liquefaction.

As for B3 ~ B6, the floating-type improvement cases, the

settlements were a little larger than those of B2 in each shaking

step. However, the settlements of B3 ~ B6 were much smaller

than those of B1, and the improvement effect of the floating-

type was confirmed in terms of ground settlement. Especially,

the settlement of B1 increased in every step, and ones of B3 ~

B6, meanwhile, did not increase. Therefore, the floating-type as

well as the fixed-type was found to be effective against the

ground settlement by liquefaction.

4 CONCLUSIONS

This paper examined the countermeasure effect of the floating-

type and lattice-shaped cement treatment method by using the

numerical analyses and the centrifuge model tests. The main

mechanism of this method as a liquefaction countermeasure was

that the floating-type treated soil reduced the shear stress that

was generated in the stratum between treated soil and

unliquefiable stratum. This effectiveness was confirmed by the

one-dimensional numerical analyses. The centrifuge model tests

resulted that the synchronism of the floating-type treated soil

and the unliquefiable stratum could restrict the generation of

excess pore water pressure the in-between stratum as well as the

unimproved soil inside the girds. In addition, the floating-type

improvement was found to decrease the ground settlement, and

the improvement effect became larger by deepening the depth

of the floating-type treated soil.

1.0

0.5

0.0

E.P.W.P.

u/

'

200

150

100

50

Time (sec)

Major strong motion

G.L.-3.5m (Pwp1)

G.L.-7.0m (Pwp2)

1.0

0.5

0.0

E.P.W.P.

u/

'

200

150

100

50

Time (sec)

Major strong motion

G.L.-3.5m (Pwp1)

G.L.-7.0m (Pwp2)

1.0

0.5

0.0

E.P.W.P.

u/

'

200

150

100

50

Time (sec)

Major strong motion

G.L.-3.5m (Pwp1)

G.L.-7.0m (Pwp2)

Figure 8. Time histories of excess pore water pressure at Pwp1 and

Pwp2: upper; unimprovement case (B1), middle; fixed-type

improvement case (B2), floating-type improvement case (B4)

1.0

0.8

0.6

0.4

0.2

0.0

Ground settlement (m)

6 5 4 3 2 1 0

Shaking step No.

B1

B2

B3

B4

B5

B6

1.0

0.8

0.6

0.4

0.2

0.0

Ground settlement (m)

6 5 4 3 2 1 0

Shaking step No.

B1

B2

B3

B4

B5

B6

Figure 9. Cumulative ground settlement: upper; top of lattice-shaped

mold at Dp1, lower; top of ground surface inside grid at Dp2

ACKNOWLEDGEMENTS

A part of this research was conducted within the collaborative

project of Port and Airport Research Institute, Penta Ocean

Construction Co., Shimizu Co., Takenaka Civil Engineering &

Construction Co., Toa Co., Toyo Co., and Fudo Tetra Co. The

authors are very grateful for their valuable cooperation in our

work.

REFERENCES

Kitazume M. and Miyajima S. 1995. Development of PHRI Mark II

geotechnical centrifuge.

Technical Note of the Port and Harbour

Research Institute

(817), 1-33.

Okamura M. and Inoue T. 2012. Preparation of fully saturated models

for liquefaction study.

International Journal of Physical Modelling

in Geotechnics

12(1), 39-46.

Takahashi H., Kitazume M. and Ishibashi S. 2006a. Effect of deep

mixing wall spacing on liquefaction mitigation.

Proceedings of the

International Conference on Physical Modelling in Geotechnics

1,

585-590.

Takahashi H., Kitazume M., Ishibashi S. and Yamawaki S. 2006b.

Evaluating the saturation of model ground by P-wave velocity and

modeling of models for a liquefaction study.

International Journal

of Physical Modelling in Geotechnics

6(1), 13-25.

Takahashi H., Yamawaki S., Kitazume M. and Ishibashi S. 2006c.

Effects of deep mixing method on liquefaction prevention and

proposal on new arrangement of grid-type improvement.

Report of

the Port and Airport Research Institute

45(2), 135-167. (in

Japanese)