1625

Technical Committee 203 /

Comité technique 203

0

100

200

300

400

500

600

Vertical position (mm)

-1200

CASE1 : No improvement

■ :

Inclinometer

Initial surface

Subsidence

-1000 -800 -600 -400 -200 0 200 400 600 800 1000 1200

Holizontal position (mm)

Uplift

lateral deformation by connecting them to a 5 mm-thick plastic

boards. By assuming the scale ratio of 1/20, the prototype

diameter of the columns is 520 mm. The range of soil

improvement (shown by orange color in Fig. 5) is 600 mm in

length and 390 mm in width with the improvement ratio of 25%.

200

380

40

40

40 40

40

45 45 45 45

50

0

100

200

300

400

500

600

Vertical position (mm)

-1200

CASE2 : Irregular 25%

■ :

Inclinometer

Improved area Initial surface Subsidence

-1000 -800 -600 -400 -200 0 200 400 600 800 1000 1200

Holizontal position (mm)

Uplift

0

100

200

300

400

500

600

Vertical position (mm)

-1200

CASE4 : Regular 25%

■ :

Inclinometer

Initial surface Subsidence

Improved area

-1000 -800 -600 -400 -200 0 200 400 600 800 1000 1200

Holizontal position (mm)

0

20

40

60

80

100

120

140

160

0

20

40

60

80

100

120

140

160

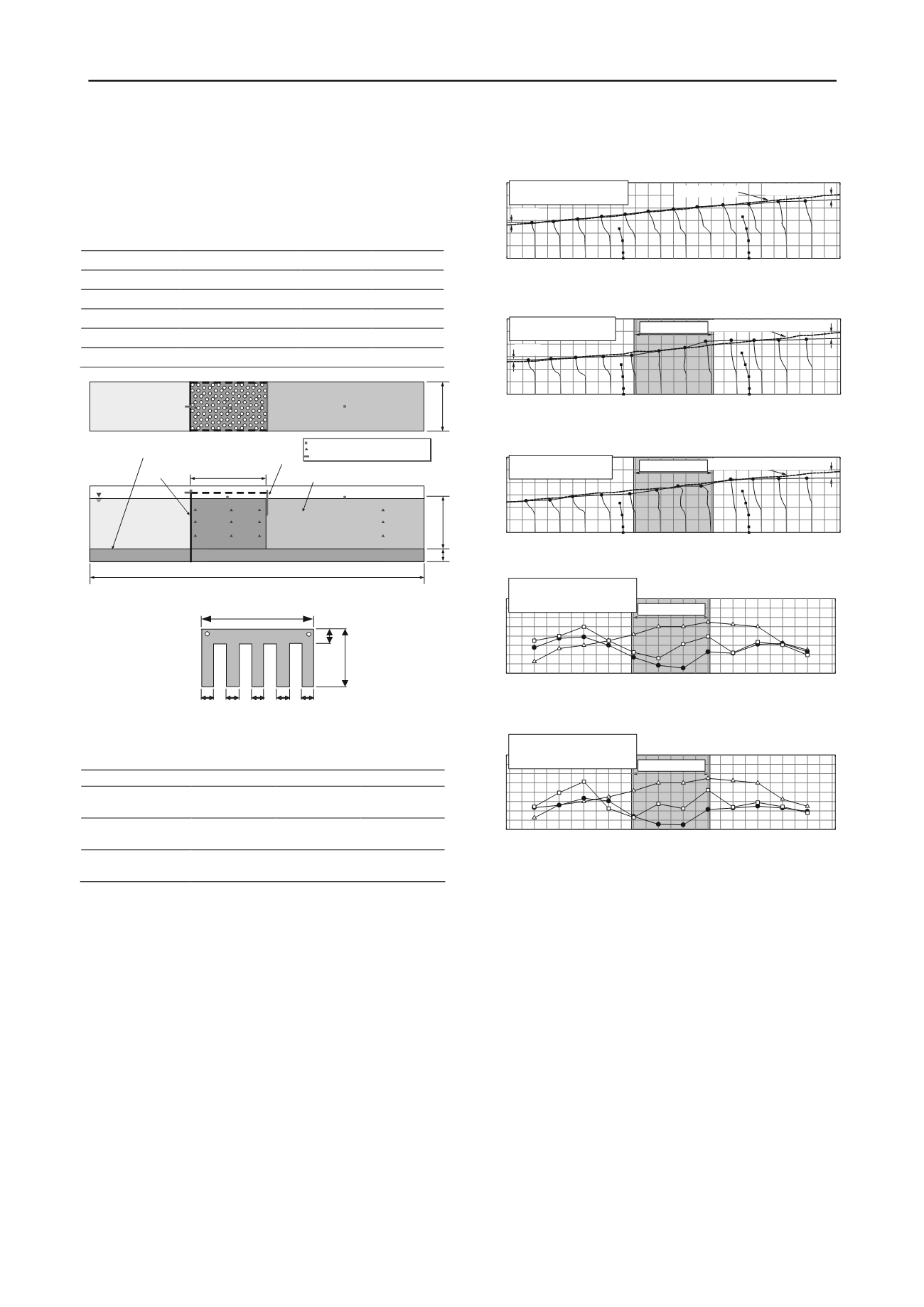

Lateral displacement (mm)

-1200

△

:CASE1(No improvement)

●

:CASE2(Irregular 25%)

□

:CASE4(Regular 25%)

-1000-800 -600 -400 -200 0 200 400 600 800 1000 1200

Holizontal position (mm)

Lateral displacement (mm)

-1200

△

:CASE1(No improvement)

●

:CASE3(Irregular 35%)

□

:CASE5(Regular 35%)

-1000-800 -600 -400 -200 0 200 400 600 800 1000 1200

Holizontal position (mm)

Improved area

Improved area

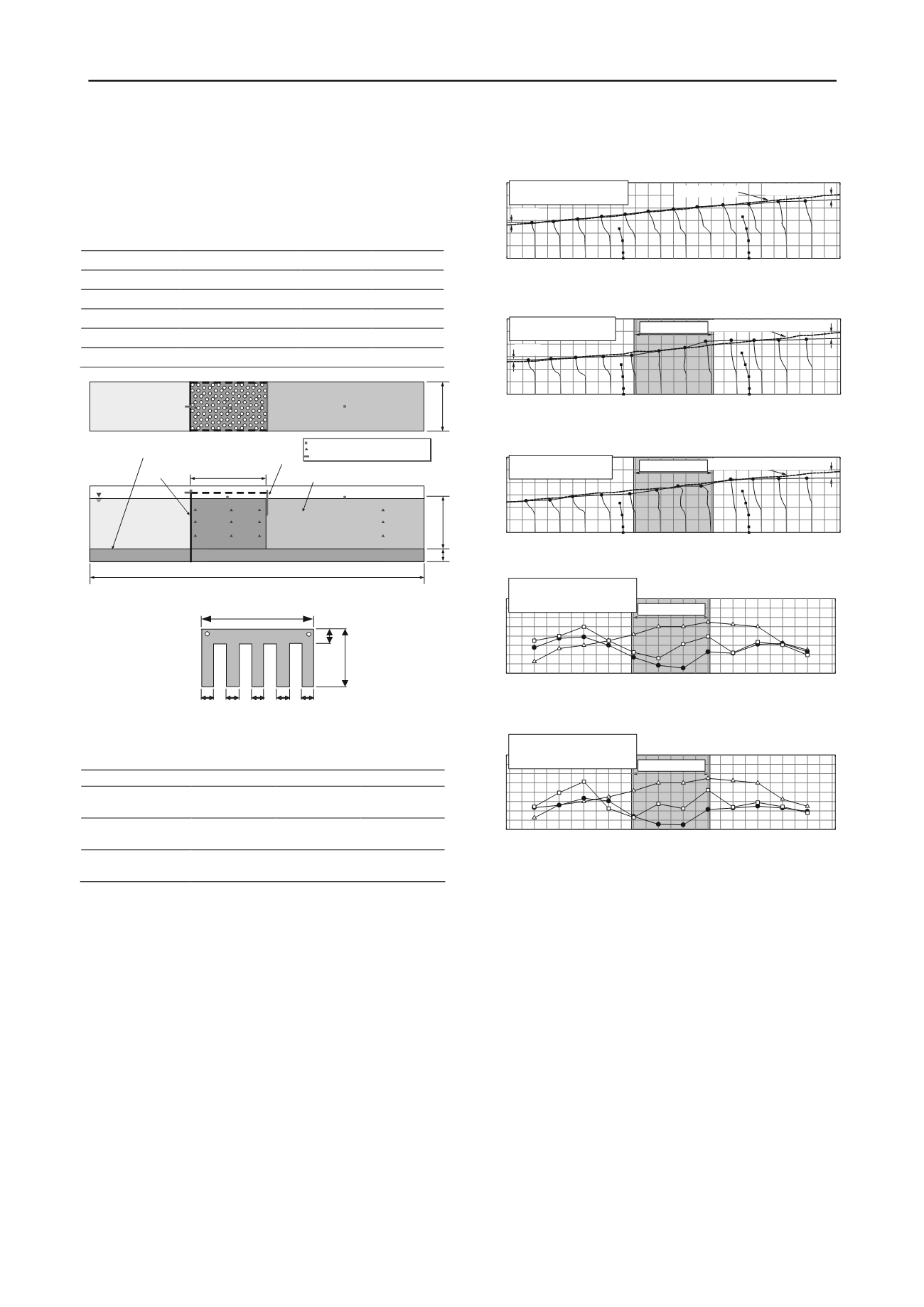

Water

Compacted sand (Non-liquefied layer)

D

r

= 85 %

100 400

Loose sand (Liquefied layer)

D

r

= 40%

(mm)

Anchorage

600

Quay wall

Improved area

2650

390

Accelerometer

Pore water pressure transducer

Displacement transducer

A1 A2

A3

P1

P4 P7

P10

P2

P5 P8

P11

P3

P6 P9

P12

Table 2. Similitude law for 1-G model tests

Items

Model/Prototype

Prototype

Model

Scale(N=20)

1/N

1

0.05

Pile diameter

1/N

520mm

26mm

Frequency

N

-0.75

1.06Hz

10Hz

Relative density

60% 40%

Acceleration

1

200Gal

200Gal

Figure 5. Schematic view of quay wall model

Figure 6. Vertical shape of anchorage plate (connected with quay wall at

top left and right by rods; see white circles there)

Table 3. Details of quay wall model

Test case

CASE6

CASE7

CASE8

Configuration of

columns

-

Irregular

Regularly

triangular

Improvement ratio

(%)

0

25

25

Maximum

acceleration (Gal)

200, 500

The sheet-pile quay wall was modeled by an aluminum plate

having 3 mm thickness and 510 mm height with its width equal

to that of the soil box. The bottom of the wall was placed in a

socket at the bottom and had no mechanical fixing. This wall

was supported by an anchorage.

Accelerometers and pore pressure transducers were

embedded in the model ground, while acceleration and

displacement at the top of the sheet pile wall were recorded as

well (Fig. 5). Further, motion picture was taken of the lateral

cross section of the ground in which lines of colored sand was

installed for easy interpretation.

The base shaking is identical with the one in Fig. 4 with the

maximum acceleration of either 200 or 500 Gal. For details of 3

tests run, see Table 3. Both regular (triangular) and irregular

configurations of columns were tested with the improvement

ratio of 25 %.

4 RESULTS OF SLOPING GROUND MODEL

Deformations of testes models are illustrated in Figs. 7-9. While

deformation of vertical columns of colored sand in contact with

the side window is shown by black lines, the inclinometer data

in the central part of the mode is indicated by black dots. First,

the deformation of ground without columnar improvement

Figure 7. Deformation of sloping ground model of Case1

Figure 8. Deformation of sloping ground model of Case2

Figure 9. Deformation of sloping ground model of Case4

Figure 10. Lateral displacement at the surface at the end of shaking

(improvement ratio 25%)

Figure 11. Lateral displacement at the surface at the end of shaking

(improvement ratio 35%)

(Case 1) shows that the most part of deformation occurred in the

upper liquefied layer, while the deformation in the unliquefiable

base layer is insignificant. The higher upstream side subsided

and the lower downstream side uplifted, consequently reducing

the slope gradient. Second, the Case 2 test with the irregular

column configuration developed uplift in the upstream

proximity of the improved area (+200 to +500 mm) probably

because the columns reduced and dammed the lateral flow of

liquefied sand. This finding is a good contrast with the

deformation of Case 4 (triangular configuration) where the

lateral flow of liquefied sand was easier. Similar difference was

observed in the cases of 35% improvement ratio as well.

Figures 10 and 11 compare the lateral displacement at the

top (at the surface) of colored sand as indicated by black dots

(inclinometers) in Figs. 7 to 9. It is first found that cases with

any kind of column configuration (Case 2 to 5) was of less

extent of displacement than in Case 1 without columns. Thus,

columns mitigate the lateral displacement of liquefied subsoil.

Further, the cases with the irregular configuration (Cases 2 and

3) showed the displacement even smaller than in the cases of

triangular configuration (Cases 4 and 5). Thus the mitigative