1620

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

performed to demonstrate the effect in a stress condition

corresponding to a proto-type scale. There were two series of

model tests, which were called Series A and B. In Series A,

rigid side-walls of a specimen box were used to reduce the

lateral displacement of the floating-type treated soil. Meanwhile,

a fixed-type structure was placed at the side of the floating-type

treated soil in Series B. Through these series, the effect of

countermeasure was examined.

2 VERIFICATION OF MECHANISM

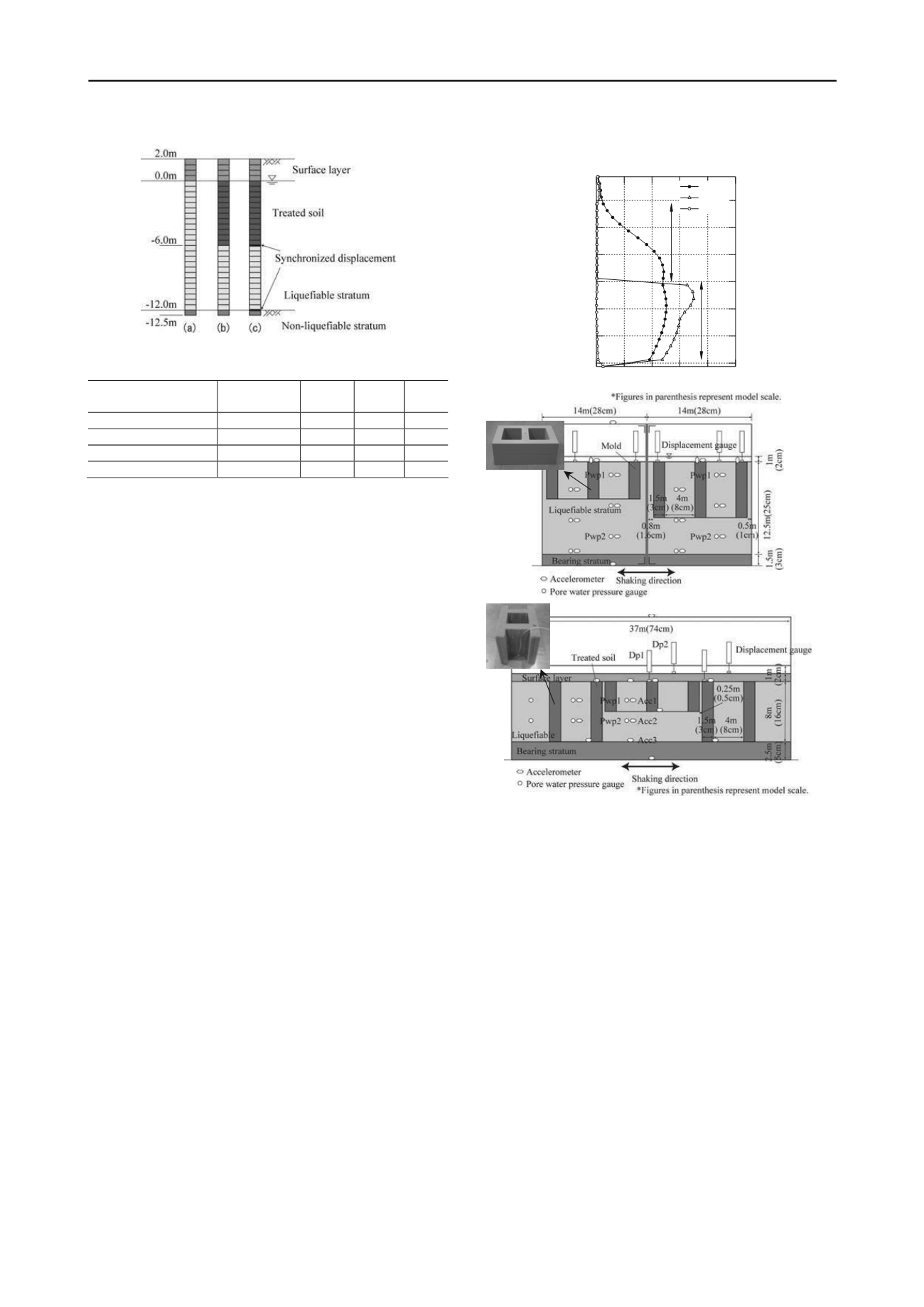

One-dimensional dynamic response analyses besed on a finite

element method were used to assess the amplitude of shear

stress of the stratum between the floating-type treated soil and

unliquefiable stratum. Figure 3 shows the analytical model, and

Table 1 is the list of soil parameters for the anayses. Case a was

for unimproved ground, and Cases b and c were for improved

ground. The lateral motions of the floating-type treated soil and

unliquefiable stratum were synchronized in Case c, not in Case

b. An elasto-plastic hyperbolic model was used for surface and

liquefiable layers as constitutive relations, and a linear elastic

model was for cement treated soil and unliquefiable layer.

Generation of excess pore water pressure was not modeled,

because the analyses were mainly conducted to verify low shear

stress of unimproved ground. The sinusoidal waves were input

for the numerical models, and its maximum amplitude and

shaking period were 3.0 m/s

2

and 20 seconds, respectively.

Figure 4 shows the depth distribution of maximum shear

strain calculated. As shown in Fig. 4, the shear strain at the

deeper stratum in Case b as well as Case a significantly

increased. With the large shear strain being generated, the

deeper stratum will be liquefied. In contrast, the shear strain at

the deeper stratum in Case c remained small due to the

synchronism of the motions of floating-type treated soil and

unliquefiable stratum. Thus, the synchronism of floating-type

treated soil and unliquefiable stratum takes effect, restricting

shear stress and liquefaction of in-between unimproved stratum.

3 CENTRIFUGE MODEL TESTS

3.1

Test model and procedures

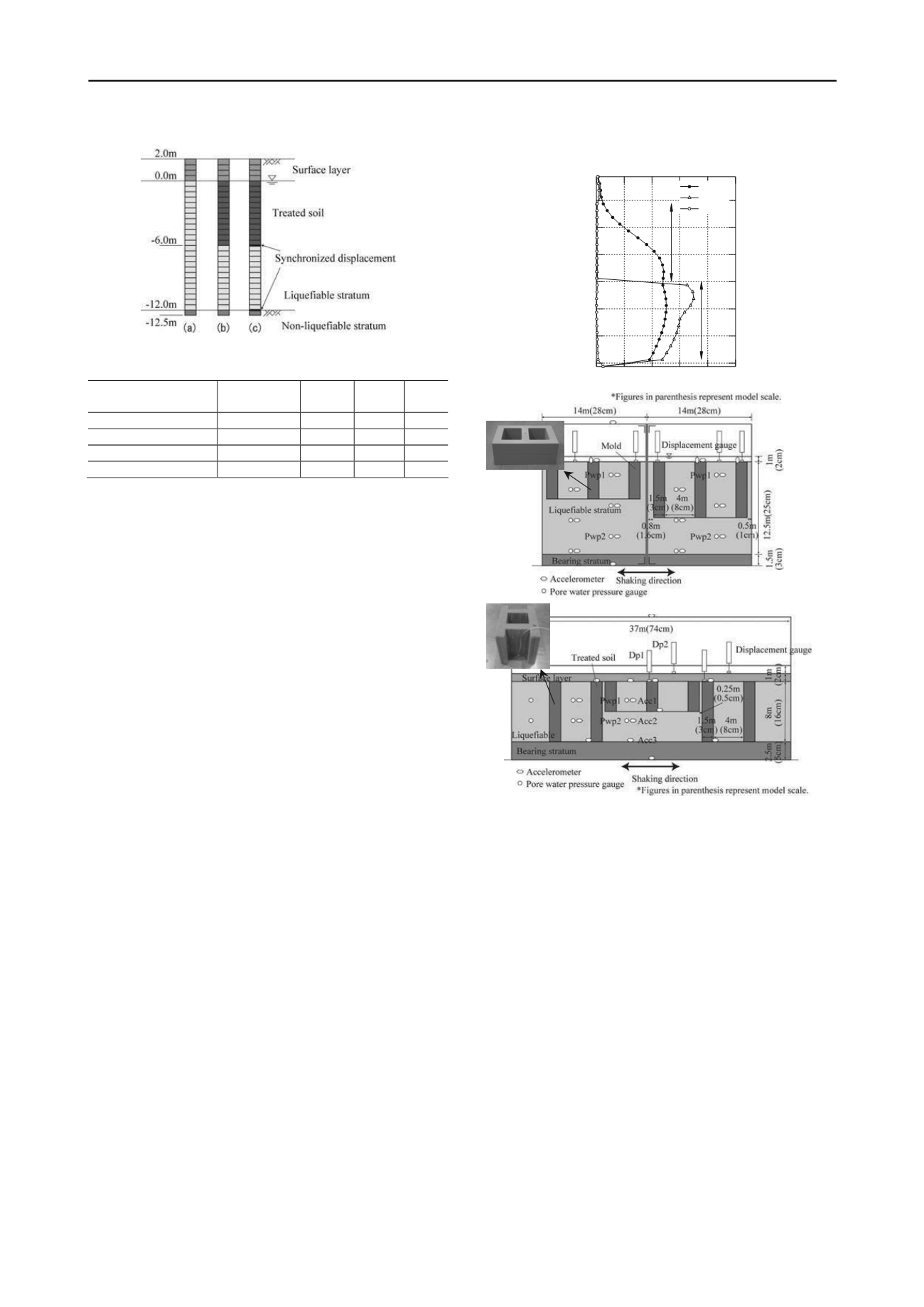

Figure 5 shows cross-section views of models in Series A and B,

and Table 2 is the list of test cases. As for the width of floating-

type treated soil, it was shortened because of the limitation of

width of specimen box used. Series A used the specimen box

with the height of 20.0 m, the width of 28.0 m, and the depth of

9.0 m, although these values are converted to proto-type scales.

Meanwhile, Series B used the specimen box with the height of

25.0 m, the width of 37.0 m, and the depth of 10.0 m.

-12

-10

-8

-6

-4

-2

0

Depth (m)

5 4 3 2 1 0

Maximum shear strain (

xy

)

max

(%)

Improved

Unimproved

Case a

Case b

Case c

Figure 4. Shear strain distribution

Table 1. Soil parameters for numerical analyses

G

0

(MN/m

2

)

(

’

=98kN/m

2

)

(g/cm

3

)

(deg.)

h

max

Surface layer

62

1.84 39.0 0.24

Treated soil

150

2.04

-

-

Liquefiable layer

62

2.04

39.0

0.24

Non-liquefiable layer

37

2.04

-

-

Figure 3. 1D numerical model to verify the mechanism of floating-type

method

Figure 5. Cross-section view of model grounds: upper; Series A, lower;

Series B

Firstly, a uniform unliquefiable sandy layer was prepared by

the technique of sand raining. Secondly, accelerometers and

pore water pressure gauges were hanged at their spots, followed

by another sand raining for liquefiable sandy layer. The sand

material was the cat.5 of Sohma sand that was taken in Japan.

Thirdly, the sand raining was stopped at the depth of the bottom

surface of floating-type treated soil, and the flat surface of sand

layer was formed by a vacuum. Finally, the model of floating-

type treated soil was put on the surface and filled with

liquefiable sand. The average relative densities of liquefiable

stratum were

D

r

= 46 ~ 54 % in Series A and

D

r

= 48 ~ 57 % in

Series B, respectively. In Series B, a surface layer was made to

model subgrade bed, using special cat.4 of Sohma sand. This

layer did not liquefy due to the high permeability.

The model of lattice-shaped treated soil in Series A was a

polyvinyl chloride mold, the unit weight of which was 13.7

kN/m

3

. In Series B, the cement treated soil of cat. 5 of Sohma

sand was used as the mold. It was made by mixing with sand

and early-strength cement at the dry weight ratio of 20 %. The

unconfined compressive strength of cement treated soil was

3219 ~ 5300 kN/m

2

, and the wet unit weight was 18.0 ~ 19.8

kN/m

3

. The grid spacing of lattice-shaped treated soil was set as

4 m. This spacing was based on the test result our previous

work (Takahashi

et al.

, 2006a, 2006c).