1384

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

A nonwoven geotextile served as a separation layer in

conjunction with a triangular aperture geogrid below the

aggregate layer. Based on our understanding of the site

subgrade soils and overlying pit-run aggregate, a nonwoven

geotextile was recommended for use as a separation layer.

11.3

6.3

59.6

33.2

0

20

40

60

80

100

120

0.9 meter from CL

1.0 meter from CL

Subgrade

Stress (kPa)

Stabilised Section Unstabilised Section

Table 3. Summary of geosynthetic treatments.

Type

Physical Properties

Polypropylene triangular aperture

geogrid

Radial Stiffness =

300 kN/m @0.5% strain

Polypropylene nonwoven geotextile

Weight = 8oz/yd

2

3.3 Test section construction

Four test sections were tested during this field study. All test

sections consisted of a 300mm thick layer of pit run materials

placed over the subgrade. Two sections are stabilised by a layer

of geogrid placed at the interface between the subgrade and pit

run material. Each test section was approximately 7 metre wide

by 10 metres in length. Two EPCs were placed in each test

section subgrade to monitor horizontal stress in the subgrade. In

general, the approximate angle of distribution of stress within a

properly designed geogrid stabilised section is 45 degrees.

Therefore, EPCs were placed at 0.9 metre and 1.0 metre from

the edge of the wheel path. Pit runmaterial was placed on top of

the geogrid by a CAT D8 dozer in a 900mm thick lift. After

placement of pit run material, lines were painted on the surface

of the road at 0.3 metre intervals from the centerline within the

areas over the pressure plates.

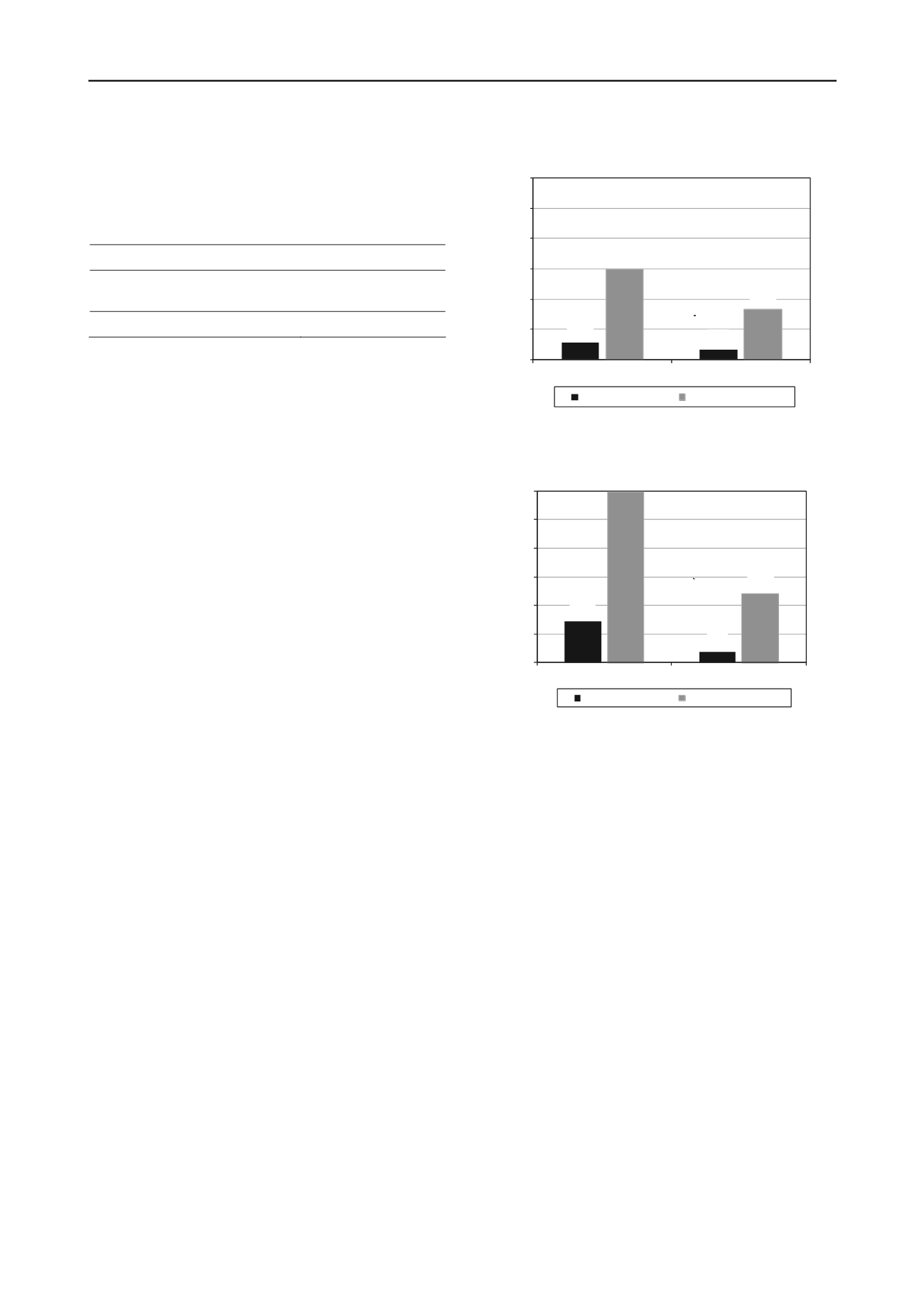

Figure 7. Subgrade pressures of 900mm sections.

28.6

7.6

119.2

48.0

0

20

40

60

80

100

120

0.9 meter from CL

1.0 meter from CL

Subgrade

Stress (kPa)

Stabilised Section Unstabilised Section

3.4 Results

Test sections were trafficked by a Volvo A40F articulated truck.

The loaded truck produces a ground contact pressure of 176 kPa

under each wheel. There was some surface movement of the fill

material (due to the smooth rounded aggregate), but no

significant deformation of the section was noticed within the

wheel path over the course of 50 passes.

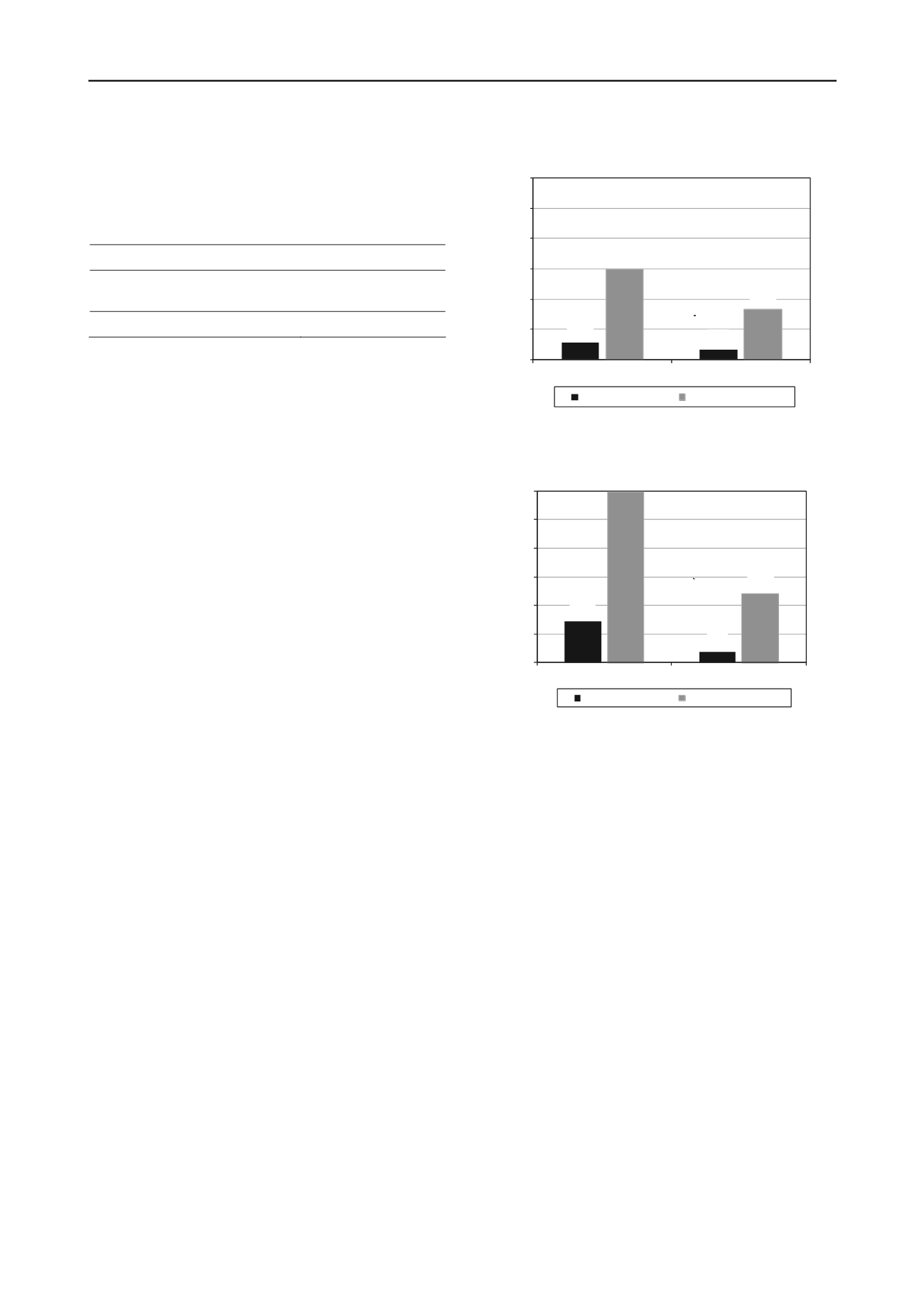

Figure 8. Subgrade pressures of 600mm sections.

The stresses as presented represent the change in ground

stresses under the accumulated trafficking passes. As expected,

higher stresses are recorded within the control section. Stress

measurements in Figure 7 indicate that the stresses of the

control section were in the range of 33 to 60 kPa depending

upon the distance from wheel path. The stresses of triangular

aperture geogrid stabilised section were in the range of 6 to

11 kPa.

4 CONCLUSIONS

The other two sections (control and stabilised) were lightly

trafficked. As no significant surface deformation was noticed

within 23 passes, sections were then cut down from 900mm in

height to 600mm by a CAT 980H loader.

Traffic resumed post-cut. Significant deformation occurred

after the first pass across the control section. The trafficking

was stopped after 1 additional pass. There was no indication of

structural distress in the stabilised section. Stress measurements

taken from the first pass are shown in Figure 8. The results

indicate that the stresses of the control section were in the range

of 48 to 120 kPa, whereas the stresses within the stabilised

section were in the range of 8 to 29 kPa.

The field tests have demonstrated benefits in terms of a

dramatic reduction in subgrade stress. Rut depth measurements

showed all geogrid stabilised sections performed significantly

better than the unstabilised controls. In-ground stress cell

measurements showed that higher horizontal stress developed

within the stabilised aggregate layer during compaction and this

was maintained throughout trafficking. The stabilisation ratio

calculated as the ratio of horizontal stresses in the base and

subgrade layers provides an indication of field trafficking

performance. Results of the second study validate the

performance of the triangular aperture geogrid examined in two

full scale trafficking studies.

5 REFERENCES

After the trafficking test was completed, trenches were

excavated to observe subgrade conditions. A significant amount

of intermixing of the pit run material and subgrade interface

occured within the 600mm thick control section. Very little

intermixing of the subgrade materials was observed in all other

sections including the 600mm thick triangular aperture geogrid

stabilised section.

Tingle, J.S. and Webster, S.L. 2003. Review of Corps of Engineers

Design of Geosynthetc Reinforced Unpaved Roads,

Annual meeting

CD-ROM, TRB

, Washington, D.C.

Rao, C., Tutumluer, E., and Kim, I-T. 2002 Quantification of Coarse

Aggregate Angularity based on Image Analysis. Transportation

Research Record (TRB) No. 1787, 117-124,.

Rao, C., Pan, T., and Tutumluer, E. 2003. Determination of Coarse

Aggregate Surface Texture Using Imaging Analysis. In Proceedings

of the 16th ASCE Engineering Mechanics Conference

White, D.J., Vennapusa, P.K.R., Gieselman, H.H., Douglas, S.C.,

Zhang, J. and Wayne, M.H. 2011. In-Ground Dynamic Stress

Measurements for Geosynthetic Reinforced Subgrade/Subbase.

Geo-Frontiers

, Dallas, Texas.