1382

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

calculated bearing capacity factor of the geogrid stabilised

section was more than double that of the unstabilised section.

This paper presents the in-ground stress cell measurements

from two full-scale field tests to validate the enhanced

confinement effect associated with use of an integrally formed

punched and drawn geogrid.

2 FIELD STUDY 1 - WEIRTON, WEST VIRGINIA, USA

2.1 Research background

A field study at a site located in Weirton, West Virginiawas

developed to evaluate the support conditions of a mechanically

stabilised crushed limestone layer on soft clayey subgrade

(White et al. 2011). In-ground piezoelectric earth pressure cells

(EPC) were used to measure horizontal stress below and above

the geogrid location versus the passage of construction and

truck traffic over the course of test pad construction and

trafficking.

Goals of this field investigation were to:

-

Validate fitness for use of geosynthetic products in a

challenging subgrade improvement application for

construction and trafficking of an unpaved road.

-

Verify the enhanced confinement effect associated with the

use of geogrid due to geogrid-aggregate interlock.

-

Verify the degree of load spreading by recording lateral

stresses within the subgrade.

2.2 Test section construction

The subgrade soils beneath the test tracks were excavated to a

depth of 900mm below the surface. The excavated material was

replaced with a uniform lean clay (CL) material. The clay

material was placed in the test tracks in uniform 0.35 metre

thick loose lifts and mixed thoroughly to a uniform consistency

with a roto-tiller. Water was added and several passes of the

tiller were used to arrive at a moisture content that produced a

subgrade California Bearing Ratio (CBR) of approximately 2 to

3 %.

Geogrids were installed on top of a finished subgrade.

Physical properties of geogrid are summarized in Table 1.

Table 1. Summary of geosynthetic treatments.

Type

Physical Properties

Polypropylene

triangular

aperture geogrid

Radial Stiffness = 300 kN/m

@0.5% strain

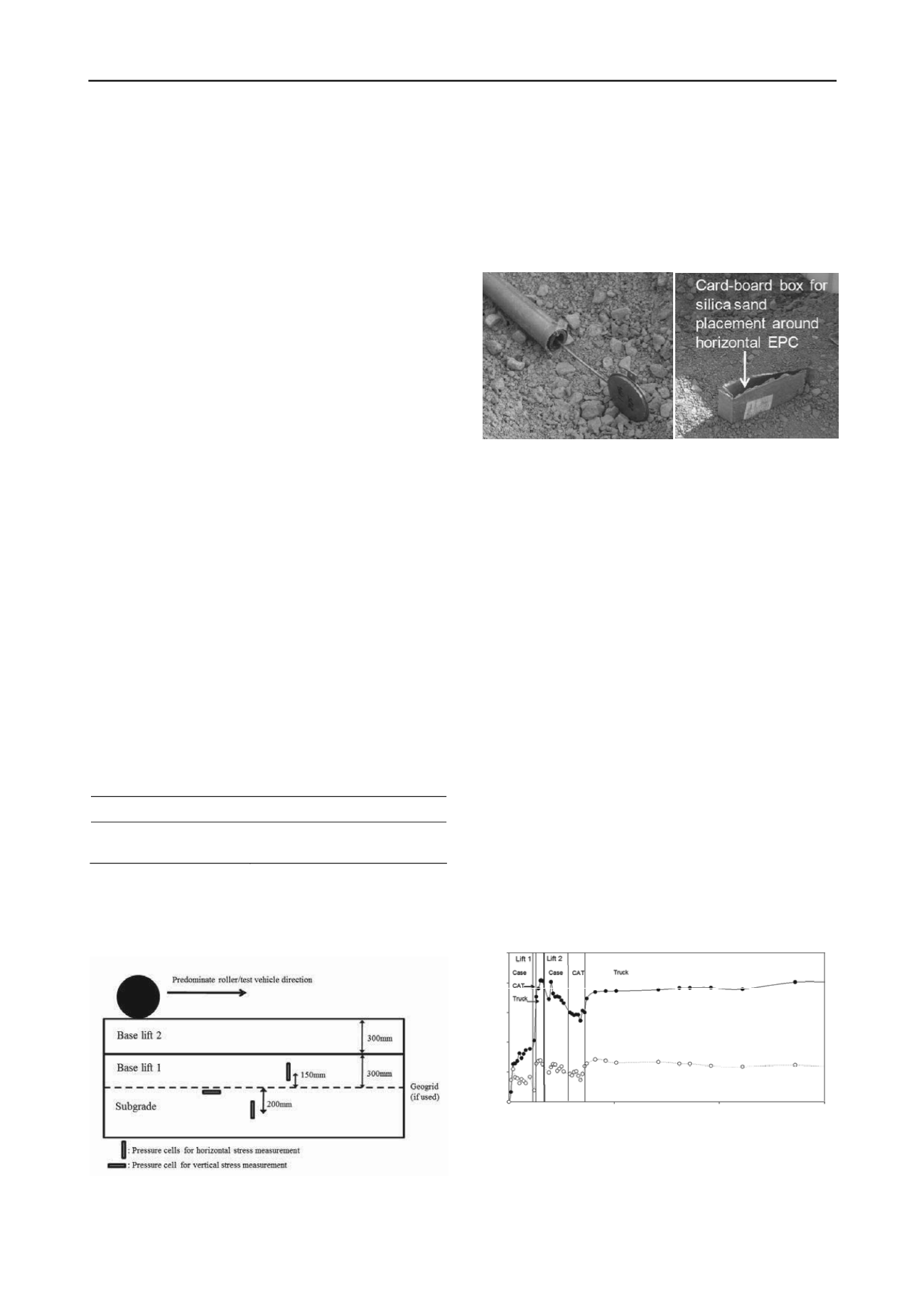

Vertical and horizontal stress measurements were taken in

the subgrade and about 150mm above geogrid/base material.

Figure 1 illustrates the layout for horizontal and vertical stress

cells.

Figure 1. Cross Section of instrumentation installation.

Then, a base course aggregate (Ohio Department of

Transportation 304, base course material) was placed in two

compacted 300mm lift thicknesses. The crushed limestone was

classified as a GP-GM with about 8 percent of fines passing the

No. 200 sieve.

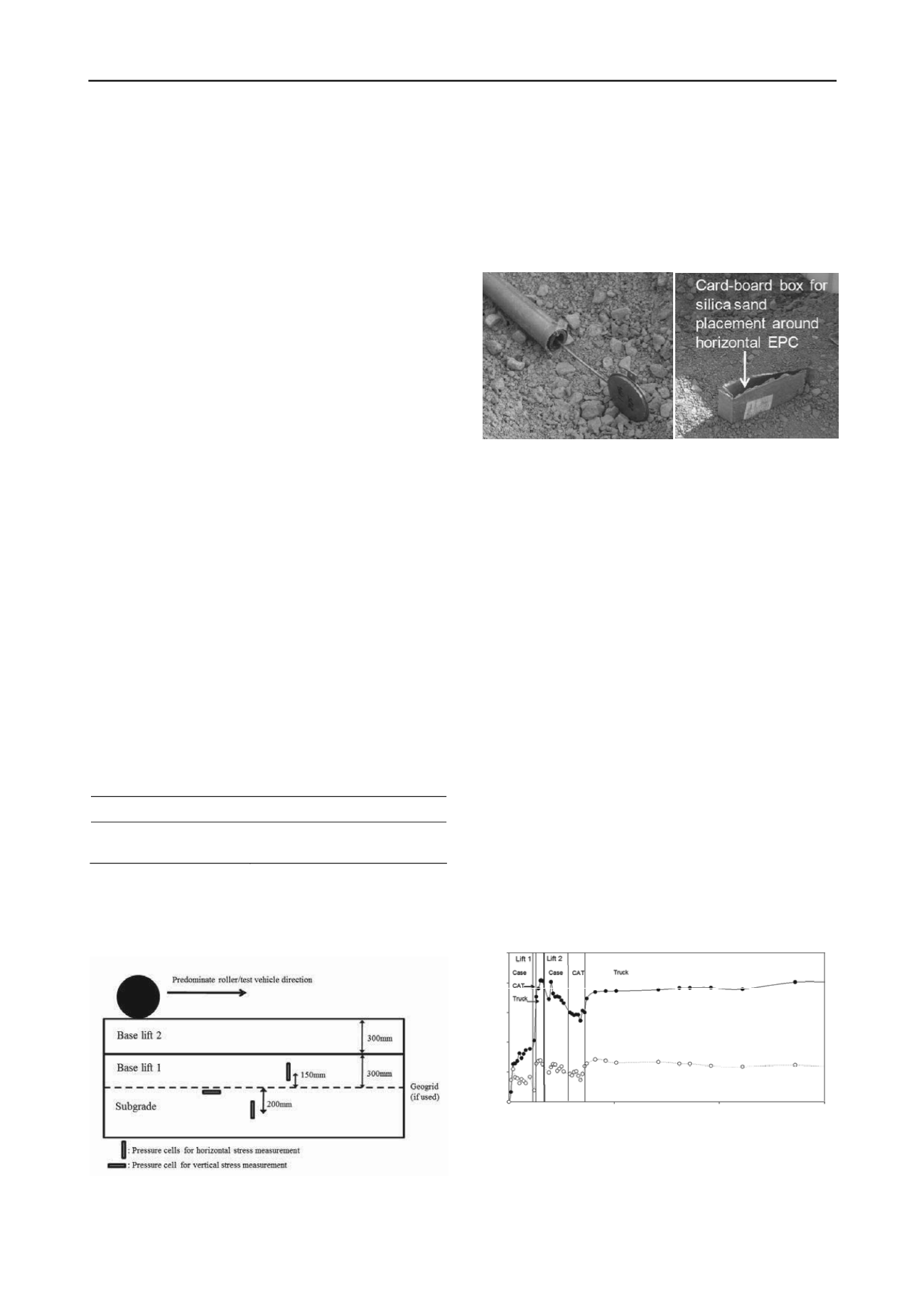

Cardboard is used as a temporary liner to contain the silica

sand backfill around the EPC (See Figure 2). Use of the sand

ensured a uniform stress was applied to the EPC surface.

Figure 2. Placing horizontal earth pressure cell at the bottom of the base

layer.

2.3 Results.

A Ford L8000 dump truck was used for trafficking of the

constructed test sections. The vehicle was loaded to a gross

vehicle weight of 18,370 kg.

Figure 3 depicts the readings of dynamic horizontal stresses

within the subgrade versus the passage of construction and truck

traffic over the course of test pad construction and trafficking.

Evident within Figure 3, is the minimal amount of horizontal

post traffic stress remaining within the subgrade in comparison

to the level found in the control section. The lateral stress below

the geogrid is a little over 5 kPa versus 20 kPa for the control

test section. This equates to a stress state value that is 25% of

the control stress state thus indicating a high level of subgrade

protection. This work demonstrated an enhanced fully confined

zone above the geogrid resulting in uniform vertical stress

across the subgrade resulting in less lateral stress.

Figure 4 depicts the horizontal stress state, post trafficking,

exhibited above geogrid. In contrast to the control, the geogrid

confines the unbound aggregate leading to an increased lateral

stress within the aggregate. The results demonstrate the

inclusion of geogrid at the interface of soft subgrade and

aggregate layers affects the development of the “locked-in”

horizontal stress following loading. A higher horizontal stress

within the stabilised aggregate layer gives a direct indication of

the lateral restraint mechanism. The result of increased

aggregate stresses leads to an increase in the resilient modulus

of aggregate adjacent to the geogrid.

25

20

15

10

5

0

50 100 150

Unstabilised section

Stabilised section

Roller/Test cumulative pass count

Stress (kPa)

Figure 3. Horizontal stress within the subgrade layer after roller

compaction and test vehicle passes (White, et. al., 2011)

.