1383

Technical Committee 202 /

Comité technique 202

25

20

15

10

5

0

50 100 150

Unstabilised section

Stabilised section

Roller/Test cumulative pass count

Stress (kPa)

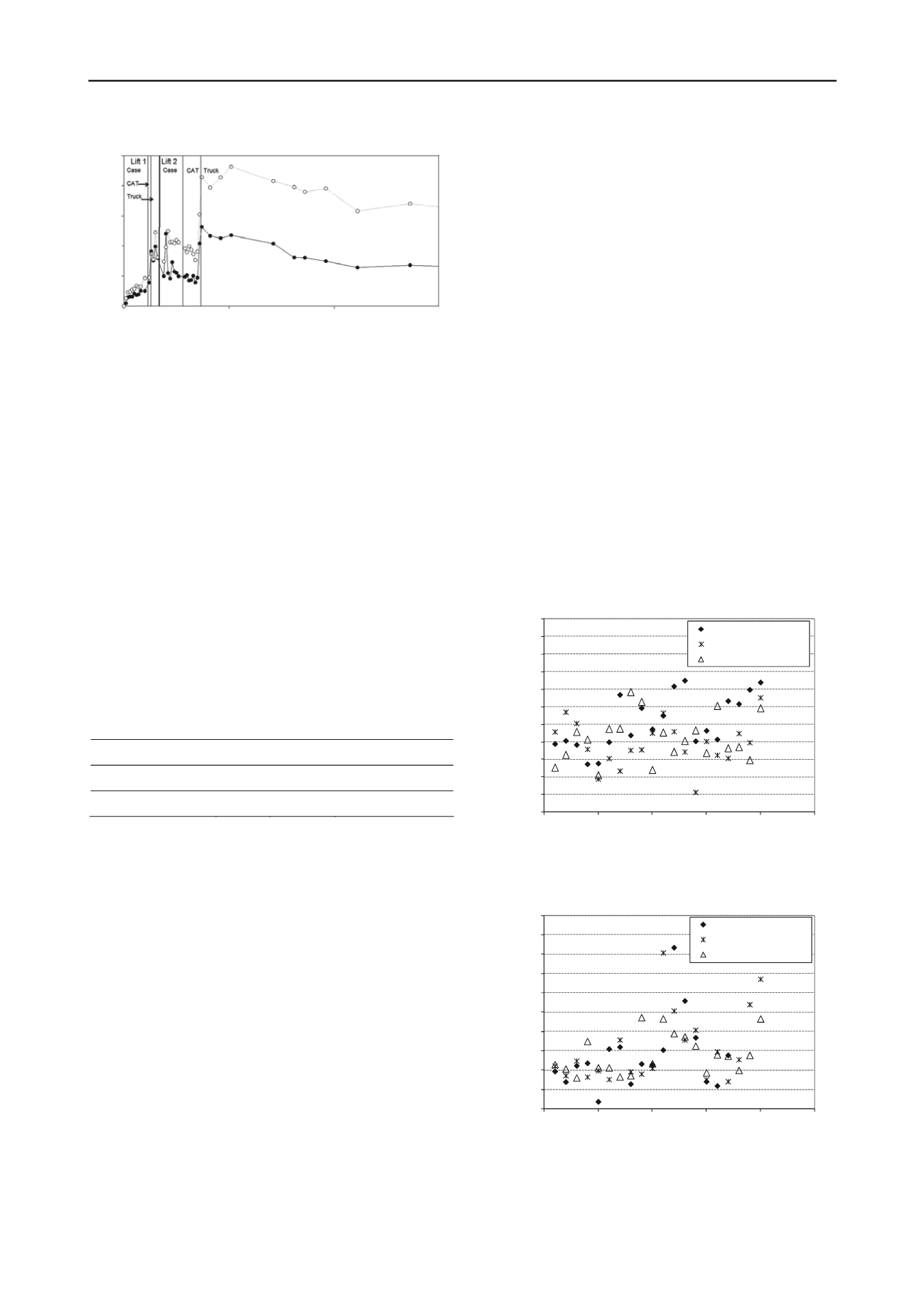

Figure 4. Horizontal stress within the base layer after roller compaction

and test vehicle passes (White, et. al., 2011).

Field determination of the relative density values for the

second or upper subgrade lift after the completion of 21 truck

passes shows 90.2% and 98.5% relative density values were

achieved on the control section and stabilised section,

respectively. These numbers demonstrated that the aggregate

placed over the geogrid can be compacted to a much higher

degree than the unstabilised control section.

Lateral stress ratio (K) is calculated as the ratio of total

horizontal to total vertical stresses for the subgrade and subbase

layers following roller and trafficking passes. Resulting values

are presented in Table 2. The calculated K values demonstrate

that during trafficking, the K values are about 0.3 to 0.7 for the

subgrade and 0.5 to 0.7 for the subbase for all test sections.

However, the K values after 75 trafficking passes show buildup

of horizontal stresses with relatively high K values in the

control section subgrade layer compared to the geogrid

stabilised section. The stabilisation ratio provides a clear

indication of degree of improvement. For this study the geogrid

results in a section that is 8 times better than the control with

regard to stress distribution.

Table 2. Performance comparison between test sections.

Section

K

subgrade

K

base

Stabilisation Ratio

Control section

3.2

1.2

0.4

Stabilised section

1.0

3.2

3.2

3 FIELD STUDY 2 - SALT LAKE CITY, UTAH, USA

3.1 Research background

A field study at a site located in Salt Lake City, Utah, United

Stated of America was conducted to evaluate the effect of a

mechanically stabilised platform to bridge over challenging soft

subgrade areas. All test sections are backfilled with 150-mm

minus pit run (unprocessed) gravel. A total of four sections

were constructed and trafficked and two of the sections were

stabilised by a layer of integrally formed punched and drawn

triangular aperture geogrid placed at the interface between the

subgrade and bridging material.

In-ground piezoelectric earth pressure cells (EPC) were used

to evaluate the support conditions of the test sections.

Measurements of tire ruts were recorded during the survey

between passes of the haul truck.

Goals of this field investigation were to:

-

Validate ability of a geogrid to reduce lateral pressures

within the subgrade under heavy loading conditions and

very soft soils.

-

Assess the ability of geogrid to stabilize pit run gravel and

quantify the benefits for different conditions and loading

scenarios.

-

Provide surface and subgrade data on heavier loading

scenarios.

3.2 Materials.

3.2.1 Subgrade soil and pit-run gravel

Test beds consisted of two materials in this study – low

plasticity clay subgrade and pit-run gravel material. A Dynamic

Cone Penetrometre (DCP) test was performed in accordance

with ASTM D6951-03 using a 4.6-kg single mass hammer.

Results were used to determine the strength of subgrade with

depth. The near surface California Bearing Ratio (CBR) for the

subgrade material varied from about 0.2% to 0.4%.

Aggregate fill material consisted of pit run gravel with a

maximum particle size of 150 mm. An enhanced, second

generation University of Illinois Aggregate Image Analyzer

(UIAIA) was used to determine morphological indices, such as

angularity index, AI (Rao et al., 2002) and surface texture index,

ST (Rao et al., 2003) of the pit run gravel used in the test.

Angularity is critical for aggregate interlock and surface texture

has been found to directly influence friction between aggregate

particles as well as the strength of the aggregate. The AI and ST

indices are determined based on the particle image outlines

obtained from each of the top, side and front of coarse particles.

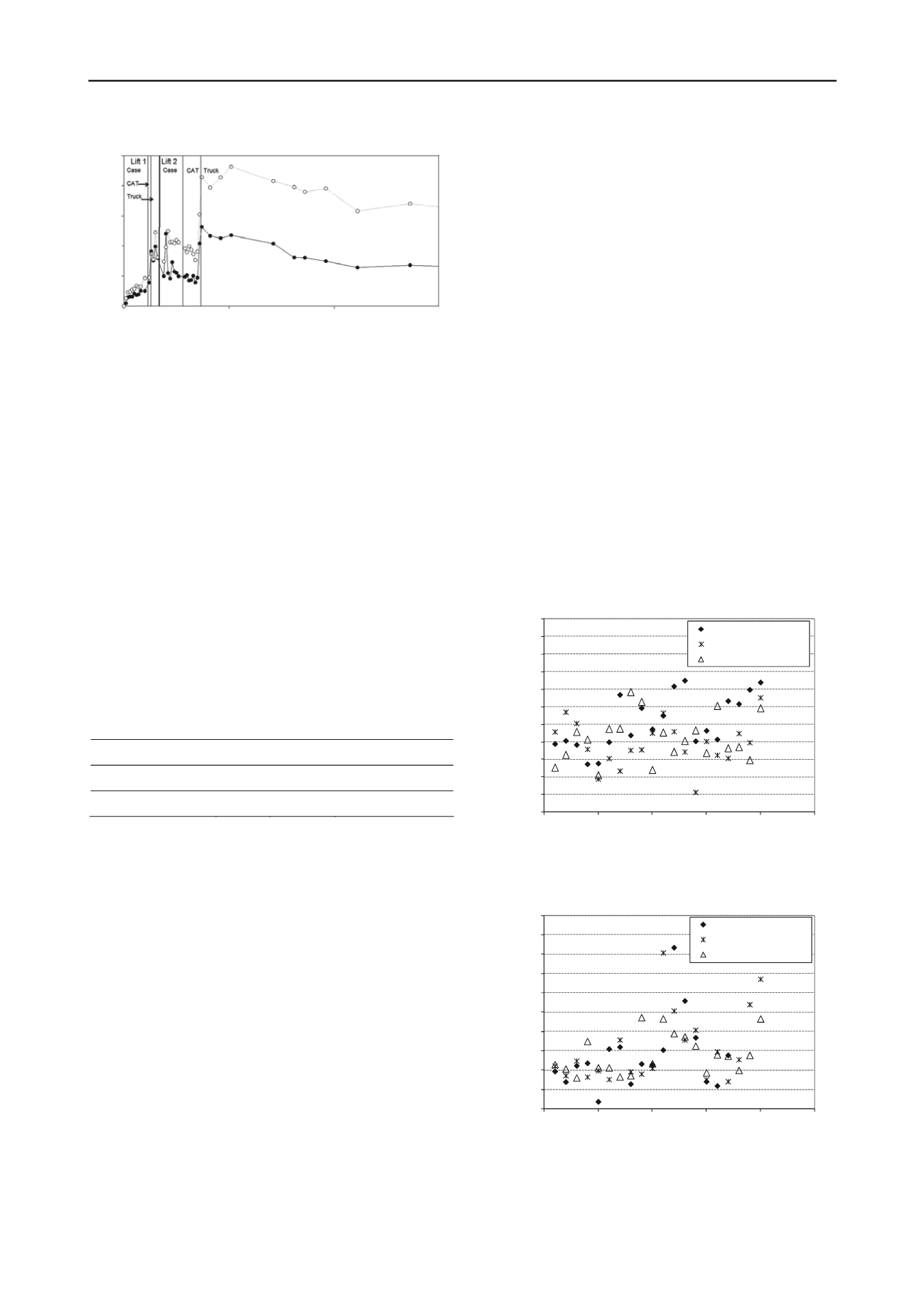

Morphological index results of the aggregate samples are

presented in Figure 5 and 6.

About 88% of the aggregate samples have angularity index

values that are less than 325 and surface texture index values

less than 1.375. These values indicate that the pit run gravel

used in this study consists of rounded and very smooth surface

aggregate particles.

0

50

100

150

200

250

300

350

400

450

500

550

0

5

10

15

20

25

Angularity

Index

Particler No.

Retained on 4.75 mm sieve

Retained on 9.5 mm sieve

Retained on 19 mm sieve

Figure 5. Angularity Indices of the Pit Run Gravel.

0

0.25

0.5

0.75

1

1.25

1.5

1.75

2

2.25

2.5

0

5

10

15

20

25

Surface

Texture

Particler No.

Retained on 4.75 mm sieve

Retained on 9.5 mm sieve

Retained on 19 mm sieve

Figure 6. Surface Textures of the Pit Run Gravel.

3.2.2 Geosynthetics

Two geosynthetic materials were used during this investigation.

Some physical properties of each geosynthetic material are

summarized in Table 3.