1375

Technical Committee 202 /

Comité technique 202

prepared with a cement content of 2%, 3%, 4% and 5% and a

degree of compaction from 83% to 86% (LC-low compaction),

and with a cement content of 2% and 3% and a degree of

compaction from 95% to 98% (MC-medium compaction). All

of these specimens have been previously tested with seismic

waves (see 1.3). For each cement content value three constant

confining pressures (30, 50 and 100 kPa) were applied, leading

to 18 tests. The triaxial tests were performed according to CEN

ISO/TS 17892-9 (2004) standard, with saturation, consolidation

and triaxial compression.

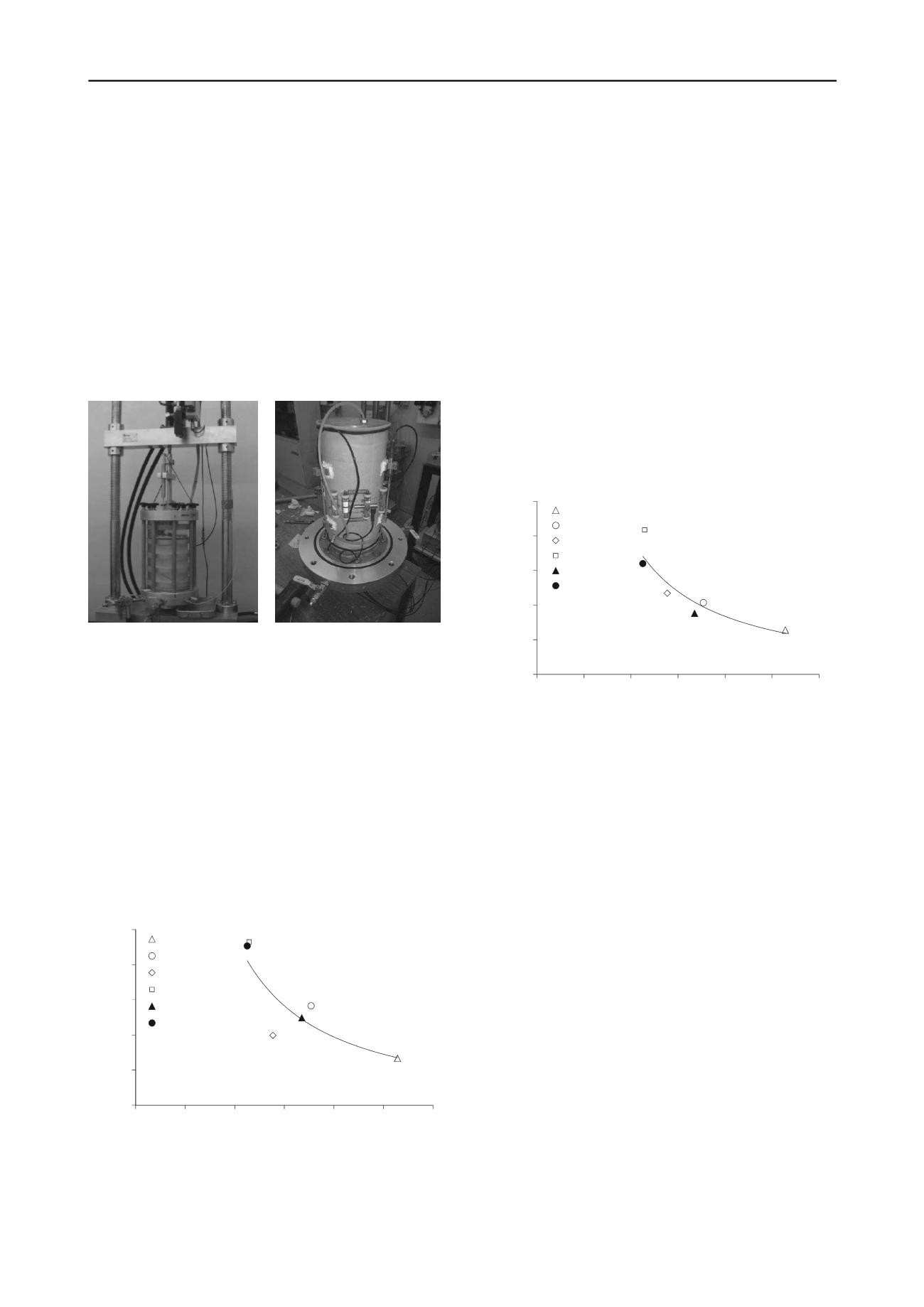

To measure the axial strain three linear variable differential

transformers (LVDT) were fixed in the specimen, while for

radial deformation, a system was developed for measuring the

variation of the perimeter using one LVDT which is mounted

between the ends of a wire that surrounds the specimen. The

wire is kept under tension by two helical springs (Figure 5).

a)

b)

Figure 5. Triaxial test equipment: a) cell and load frame apparatus; b)

axial and radial deformation transducers installed on the specimen.

During shear compression, at 0.0016 mm/second, the

specimens were submitted to two unload/reload cycles in order

to define the quasi-elastic behaviour. Some of the stress-strain

curves obtained in the tests are presented in Section 3 of this

paper, when discussing the numerical modelling of the tests.

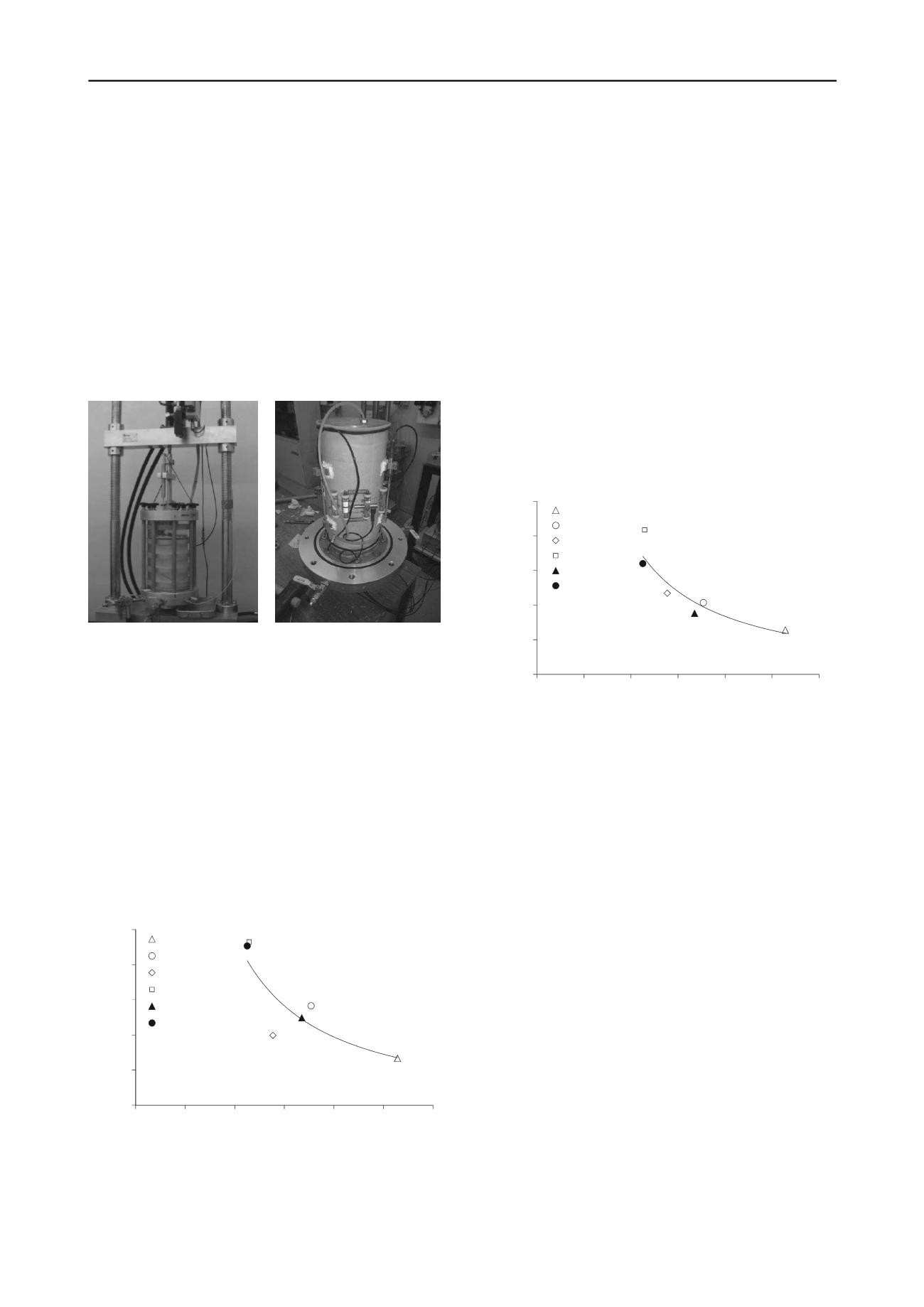

Figure 6 shows the relationship between the adjusted

porosity/cement ratio and deformability modulus computed at

50% of ultimate shear strength for specimens with confining

pressure of 100 kPa (E

50

ref

). The mixtures are referenced by the

percentage of cement and the type of compaction (for example,

2_LC means a mixture with 2% of cement content and low

compaction). In this analyses, the best correlation is also found

to an exponent of 1.0, but it is associated with a lower

coefficient of determination (R

2

=0.76) than those presented

above.

R² = 0.76

0

1

2

3

4

5

0

5

10

15

20

25

30

E

50

ref

[GPa]

n / C

iv

1.0

2_LC

3_LC

4_LC

5_LC

2_MC

3_MC

E

50

ref

= 97.71 (n / C

iv

1.0

)

-1.308

Figure 6. Relationship between E

50

ref

and

n

/C

iv

x

.

It is important to point out that, with exception of 4_LC

specimen, there was a significant increase in the deformability

modulus with increasing cement content. Furthermore, it is also

interesting to note the significant increase in deformability

modulus with degree of compaction, when comparing mixtures

having the same cement content.

Strength parameters, such as the angle of shearing resistance

(

’

) and the cohesion intercept (c’), were computed using the

results of three specimens of each type of mixture, with similar

compaction and the same cement content, for different isotropic

consolidation pressures.

With regard to the angle of shearing resistance, there is a

slight increase from 40° to 42° when the cement content

increases from 2% to 5% in the samples with low compaction.

In the samples with medium compaction it was computed a

angle of shearing resistance of 58°, regardless of the cement

content, which shows the great importance of the compaction on

the mechanical characteristics of the mixtures.

The values of c' ranged from 250 kPa to 830 kPa, reflecting a

significant increase in this parameter with the increase of the

cement content. For specimens with low compaction, the

increase from 2% to 5% in the cement content causes an

increase of c' from 255 kPa to 835 kPa. Figure 7 shows the

relationship between the cohesion intercept and the

porosity/cement ratio. The best correlation is also achieved for

an exponent of 1.0, with a coefficient of determination R

2

=0.88.

R² = 0.88

0

200

400

600

800

1000

0

5

10

15

20

25

30

c' [kPa]

n/ C

iv

1.0

2_LC

3_LC

4_LC

5_LC

2_MC

3_MC

c' = 13607 (n / C

iv

1.0

)

-1.236

Figure 7. Relationship between cohesion intercept and

n

/C

iv

x

.

Considering the presented results, it could be concluded that

it is possible to assume the value 1.0 for the exponent x, when

one intend to relate the adjusted porosity/cement ratio with

mechanical properties of these aggregates, with exception of the

tensile strength.

3 MODELLING OF TRIAXIAL TESTS

Based on the triaxial test results, a calibration of the

geo-mechanical parameters for the Hardening Soil Model

available on the commercial software Plaxis

was made. The

model parameters that were considered for each

aggregate-cement mixture are shown in Table 1.

This paper presents only the tests results and the modelling

curves (mod) for the specimens with 2% of cement content,

with low compaction (Figure 8) and with medium compaction

(Figure 9). As previously mentioned, three different values of

confining pressure were applied (30, 50 and 100 kPa). Further

details can be seen in Viana da Fonseca et al. (2012).

The analysis of Figures 8 and 9 shows that: a) the curves that

relate the deviatoric stress with the axial deformation are fairly

well approximated by the modelling curves, in particular for

mixtures with low compaction; b) it is rather difficult to model

the curves that relate the volumetric deformation with the axial

deformation, particularly for the higher values of the confining

pressure. For the tests performed on other aggregate-cement

mixtures similar trends were found.