1371

Technical Committee 202 /

Comité technique 202

Table 2. Results of calculations

Bending moment embedded

63 kNm

Bending moment retaining

65 kNm

Horizontal displacement

21 mm

Vertical displacement top of wall

4 mm

Max vertical displacement behind wall

9 mm

Load in nails row 1

140 kN

Load in nails row 2

190 kN

Load in nails row 3

217 kN

Load in nails row 4

140 kN

After excavation of a retaining height of 3 m, a guide wall

for the jet grout columns was casted against the berliner’s

soldier piles (HEB 300 beams). This guide wall also serves as

temporary waler, since execution of jet grout columns decreases

significantly the passive soil resistance in front of the soldier

piles. To counter this effect, the installation of the jet grout

columns was also carried out in a specified alternating

sequence. guide wall also serves as temporary waler,

Figure 4 shows the finite difference model geometry with

bending moments in the wall and axial loads in the nails.

Figure 4. The distribution of the nail forces along the nails and bending

moments within the jet grout wall.

The VHP jet grout columns only serve as a mean to install

the beam reinforcement at depth and to transfer earth and water

pressure to the reinforcement beams. For safety reasons, the 21

m long reinforcement beams (HEB 280) had to be installed in 3

m long sections which were bolted together. This installation is

tedious and time consuming, and has to take place before the

grout starts to harden. Due to the column length, installing the

beams can only start about 2 h after commencing the

(water)pre-cutting and 1 h after the (watercement) grouting.

Including the bolting of the different beam sections, which takes

up about 45 min in total, the last section reaches the bottom of

the column 2 h after the start of the jet grouting at that depth.

Furthermore, the VHP-piles are installed in alluvial soil.

Although the strength of the grout was not an issue (since it is

of minor importance in the design), it is challenging to realise a

reasonable sized jet grout column in this alluvium, especially

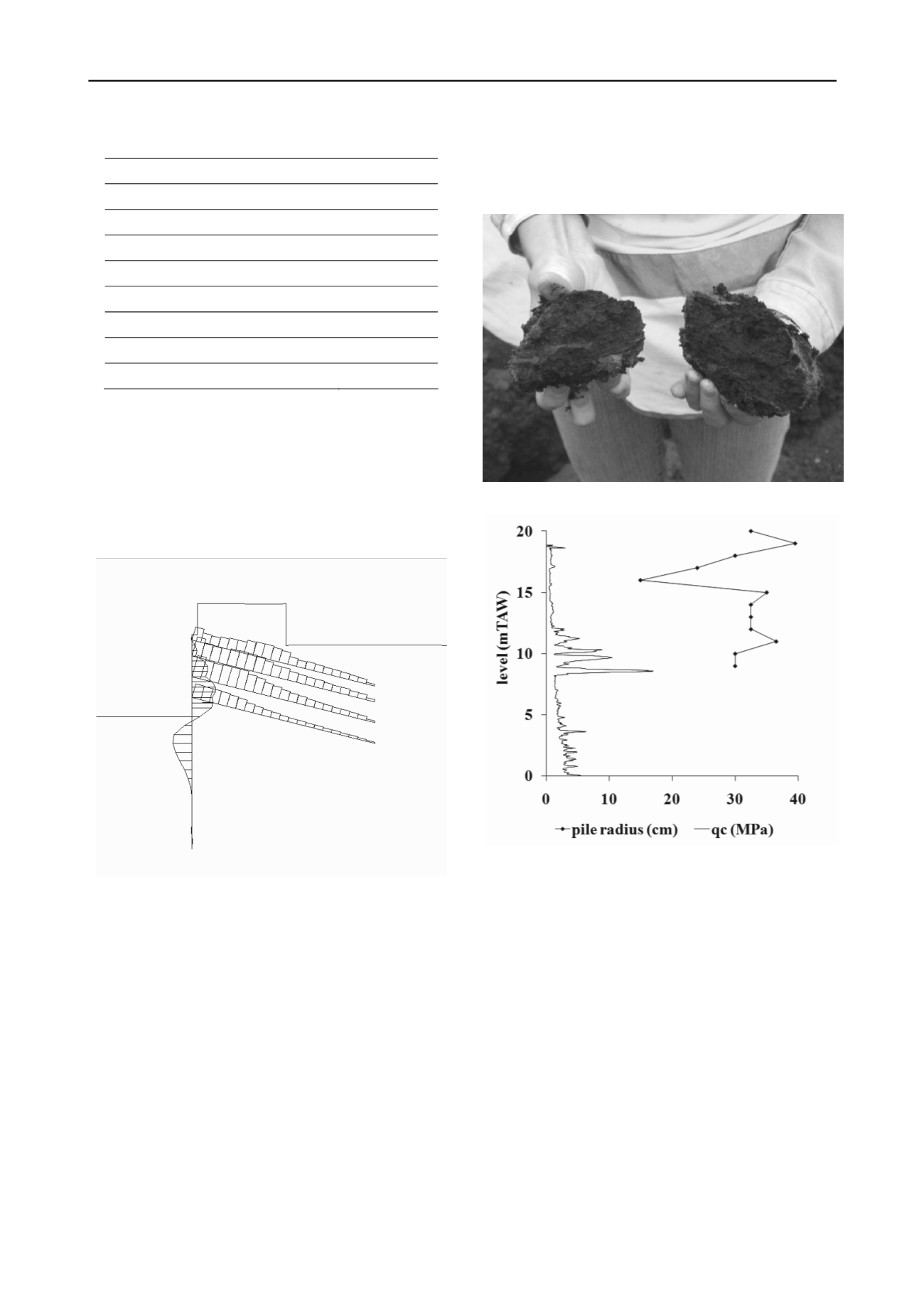

when peat is encountered. Test columns were installed prior to

the wall installation, in which diameter measurements were

carried out with a calliper in the wet column. During these tests,

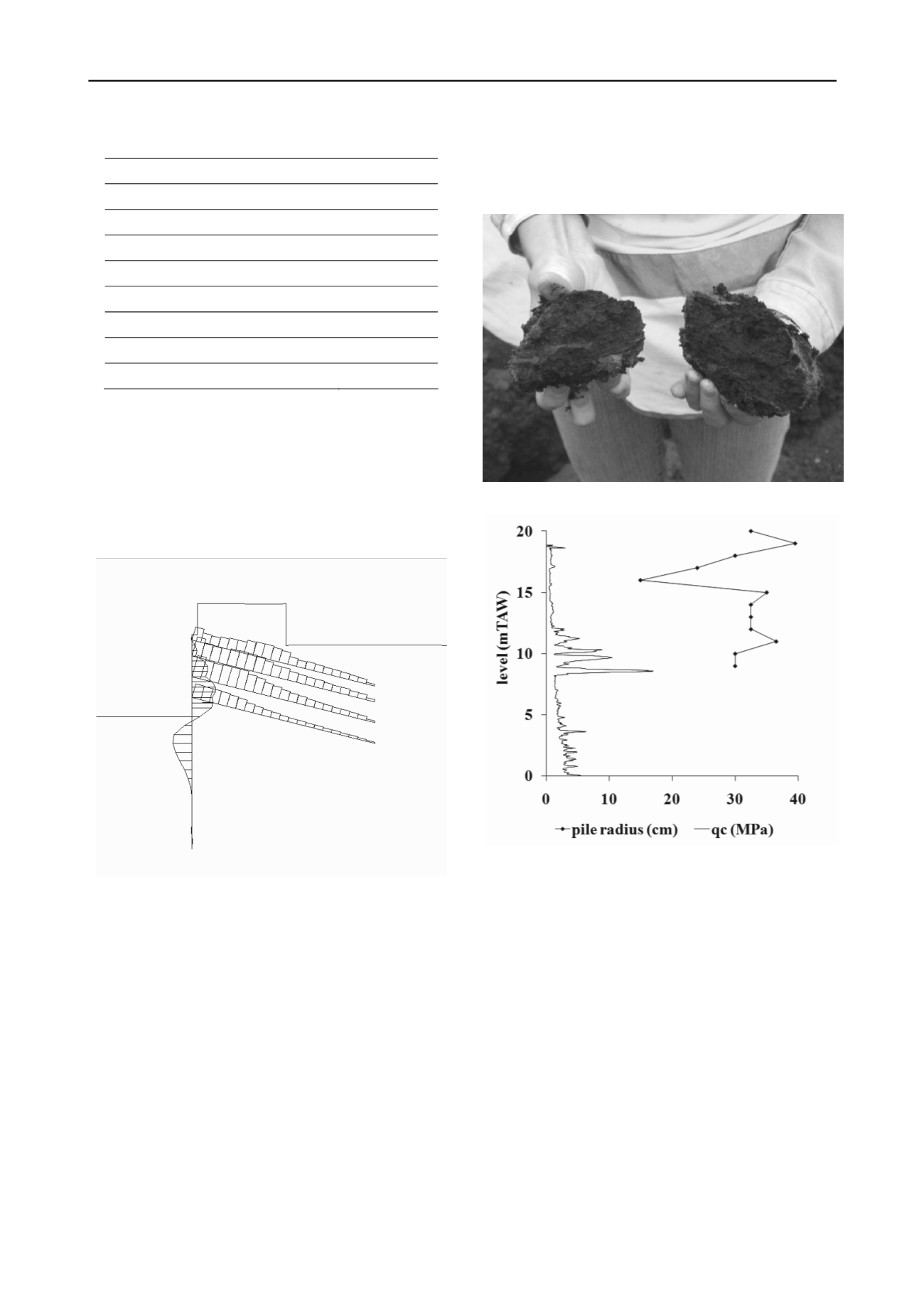

chunks of more than 10 cm diameter of compacted peat were

found in the spoil (Figure 5). To aid in the realisation of the

required diameter to install the beam reinforcement, a reamer of

30 cm diameter was placed above the jet nozzles. Even with this

reamer, the minimum diameter realized was equal to that of the

reamer (Figure 6).

Figure 5. Pieces of peat found in jet grout spoil.

Figure 6. Cone resistance from CPT-E and measured diameter in wet jet

grout column.

After testing different jetting pressures, flow rates and nozzle

diameters, a suitable set of parameters was chosen. Even with

this most suitable set, it was difficult to install the last few

meters of the reinforcement, due to decantation of soil inclusion

(clay/peat) in the grout. To ease the installation, the jet grout

columns were deepened 1 m to allow for a 1 m unreinforced

length. The retaining wall was executed as primary (reinforced)

and secondary (unreinforced) columns with hart-to-hart distance

of 1 m between reinforcements. The secondary columns serve to

fill up the gap between primary columns.

Due to the nature of the fill and natural soil, a larger

diameter than conventional soil nail diameters was necessary to

provide sufficient bearing capacity of the nails. The soil nails

were also executed as jet grout nails with a diameter of 30 cm.

Pull-out tests were performed on sacrificial nails to check the

design assumptions.

Figure 7 gives a view on the retaining wall after excavation

and creation of a working platform for the new pile foundation.