1363

Technical Committee 202 /

Comité technique 202

Table 2. Summary of Petrographic thin section result on Afram Shale

(Source: Department of Geology, Univ. of Ghana).

Sample (%)

Mineralogy

1

2

Quartz

60 - 70

55 - 65

Feldspar

5 - 15

10 - 20

Clay

10 - 20

15 - 20

Organic

Nil

Nil

Table 3. Summary of X-ray fluorescence results based on major

oxides. Source: Ghana Geological Survey Department

Element

Percentages

Na

2

O

1.39

MgO

1.52

Al

2

O

3

8.57

SiO

2

74.96

Fe

2

O

3

2.63

CaO

0.26

others

2.57

L.O.I

8.10

1.1.3

Field test

The field test carried out on the 100m stretch were the

dynamic cone penetrometer (DCP) based TRRL specification

and plate load bearing based on BS 1377:part9 1990

A total of eight (8) test points were carried out for the

DCP between chainage 29+662 and 29+712. Summary of

results is presented in Table 4.

Table 4. Summary of DCP test results

Chainage

Thickness,

mm

Ave CBR, %

29+625

131

150

29+637

43

150

29+650

103.5

140.42

29+662

35

150

29+675

221

130.33

29+687

154

150.14

29+700

69.8

150

29+712

73.5

145.07

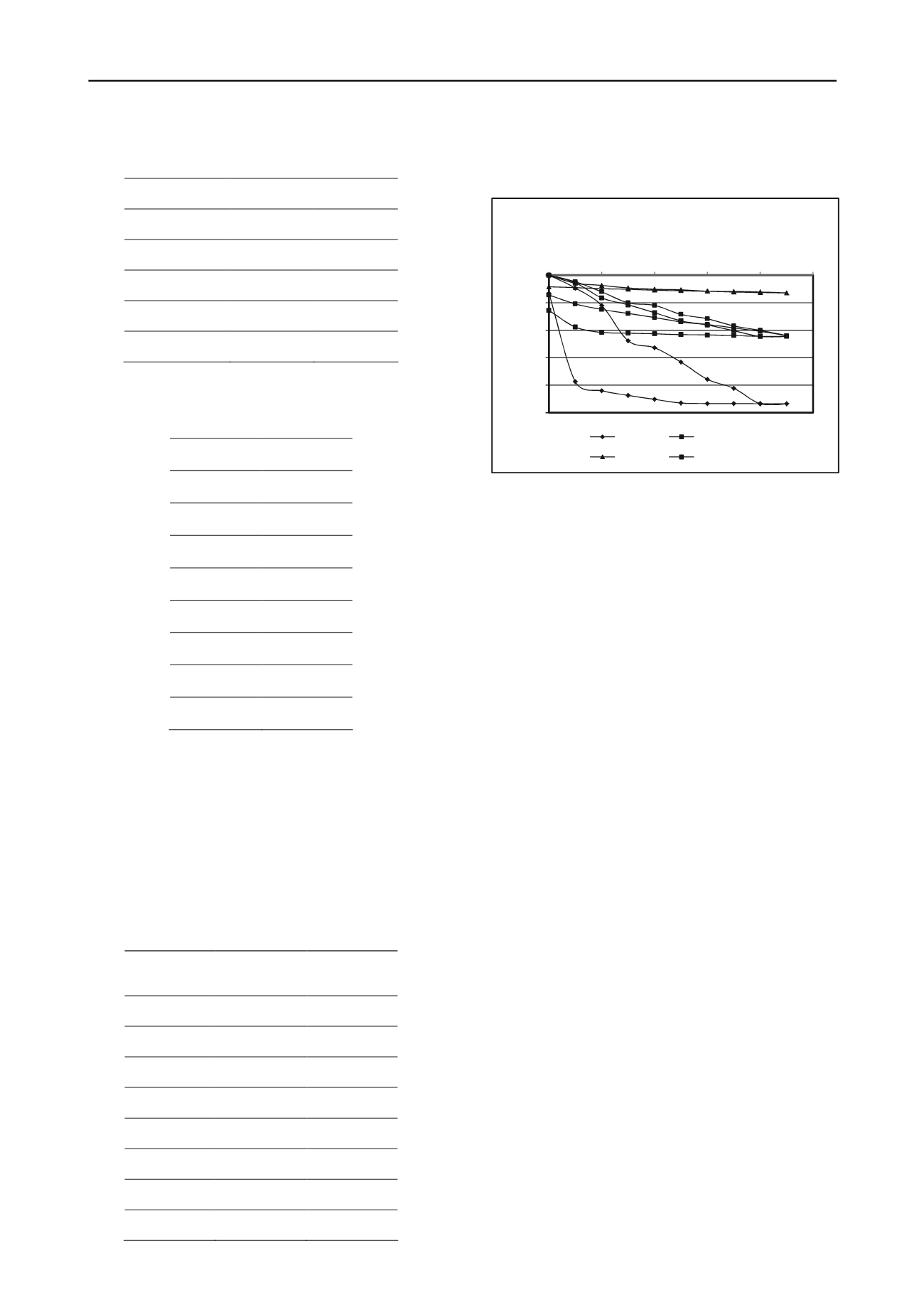

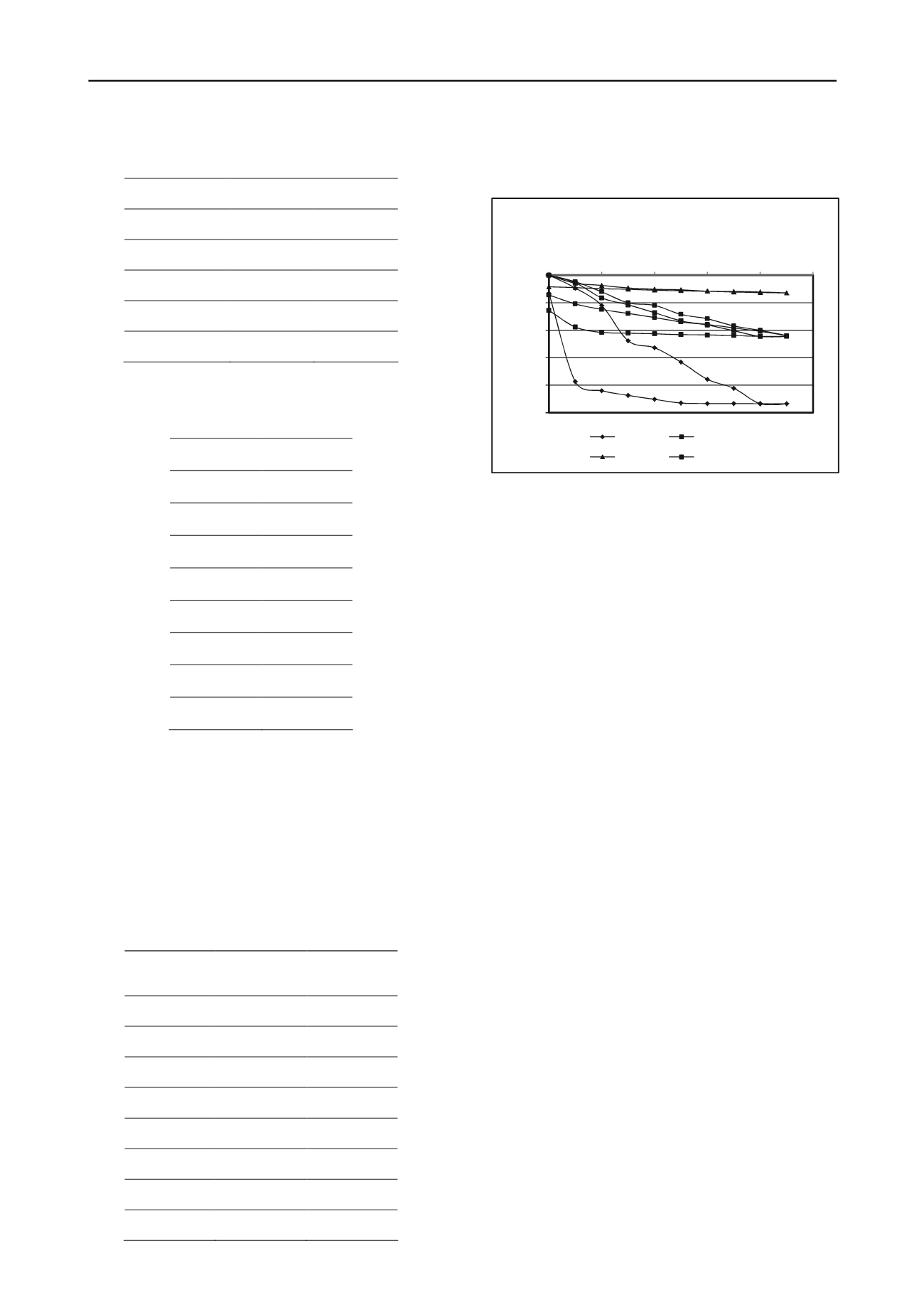

Graphical presentation of plate load bearing test and typical

field test performance are shown in Figure 1 and Figure 3

respectively.

0

0.5

1

1.5

2

2.5

0

200

400

600

800

1000

Average settlement, mm

Bearing Pressure, kN/m

2

Load - settlement curves for plate bearing test

Ch29+637

Ch29+662

Ch29+675

Ch29+712

Figure 1. Plate load bearing graphs

1.1.4

Discussion

For quality assurance and statistical representation purposes,

the shale was tested in six different laboratories to evaluate its

geotechnical properties in order to understand its intended

utilization. The conventional laboratory tests that are

normally used for classifying materials in pavement works

are gradation, Atterberg’s limits, plasticity modulus and CBR.

Atterberg’s limits results

, in Table 1, indicate that fine

content is mostly clay and inorganic of low to medium

plasticity. The plasticity modulus (PM) as per the contract

specification stated that values of, at most, 200 are assigned

as base course; those between 200 and 250 are assigned sub-

base course. The PM values obtained from the laboratories

varied between 13.7 and 461.7. These observed values

indicate that the shale could be used as base, sub-base and fill

materials. The CBR, four day soaking, values obtained range

between 8% and 12%, which falls below the expected 15%

contract specification for fill.

During the construction stages an exposed section of the

shale material on the road corridor, under traffic and

environmental conditions, gave an interesting outlook. This

prompted the implementation and evaluation of the trial

section using conventional road construction methods.

From Table 2, the petrographic analyses revealed that

the subject material is mostly siliceous. The study revealed

that the quartz had been re-worked, an indication of a

transported clastic sediment or an occurrence of a low grade

metamorphism of the material. The high SiO

2

content of

about 75% shown in Table 3 and the low clay content indicate

the siliceous nature of the shale material.

The eight DCP test points were selected randomly within

the 100m stretch. CBR values were obtained using the Kleyn

and Van Harden equation below.

Log (Cbr) = 2.628

–

1.273log (DCP)

Table 4 presents the DCP test results varying thicknesses for

CBR evaluation. The thickness column, in the Table 4,

represents total thicknesses run-by each DCP test at the

various chainage. CBR values represent average values