1370

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

The use of secant piles wall, diaphragm walls, sheet piles etc

was excluded for safety reasons, so a VHP-jet grout wall was

chosen as retaining wall.

Since both the Berliner wall and VHP-wall are closely

together and influence each other, their global design was

carried out simultaneously using the finite difference program

FLAC.

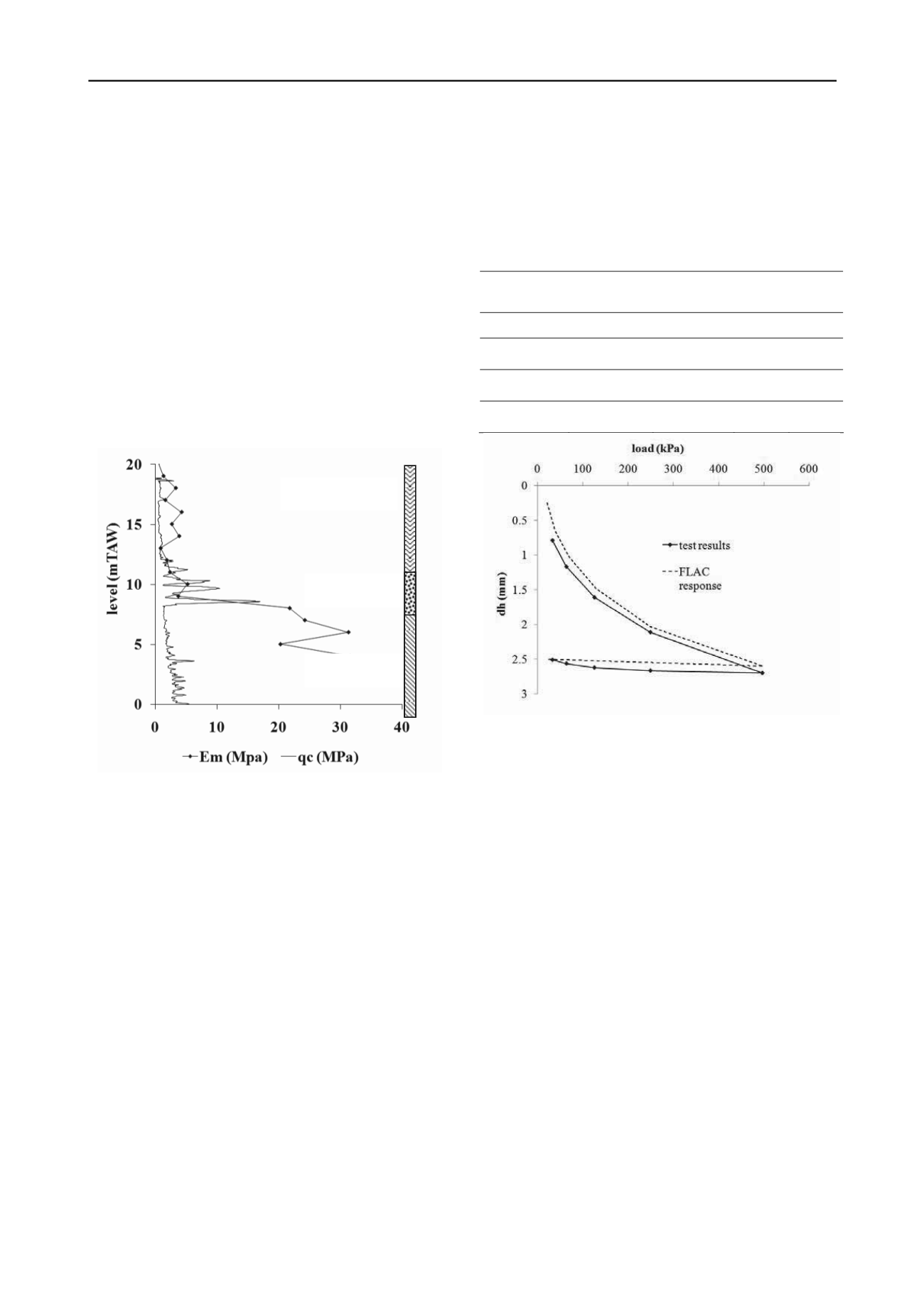

2 SITE GEOLOGY

The site is located within the alluvial basin of the river Senne,

and contains highly compressible alluvium up to a depth of 10

m. Underneath this alluvium, a gravel layer is situated with a

thickness ranging from 2 to 5 m. The deeper tertiary deposits

consist of Yperian clay, an over-consolidated clay with a

thickness of up to 16 m. Figure 2 shows the results of an

electrical CPT together with the results of a pressiometer test at

the same location. The Ménard modulus from the pressiometer

test shows the different degree of consolidation in the upper

clay layer from +8.0 to +4.0 mTAW and in the lower clay layer.

Figure 2. Cone resistance from CPT-E and Ménard modulus from

pressiometer.

3 DESIGN

3.1

Site investigation and soil parameters

Besides the extensive in situ site testing, such as cone

penetration tests (CPT’s), pressiometer tests and core drillings,

also extensive laboratory testing was carried out on undisturbed

samples. The results of these tests were used to determine the

effective strength parameters summarized in Table 1. A number

of CPT’s were performed directly from the train tracks and

through the embankment fill. The railway embankment is a

poorly compacted and silty fill.

3.2

Finite difference model

The geometry as shown in figure 1 and all of its construction

phases was modelled with the finite difference program FLAC.

Special consideration was given to the compressibility of the

alluvium. To model the stress dependant stiffness of this layer, a

“double yield” soil mechanical model was used. The double

yield model allows for plastic volumetric strain hardening,

although independent of shear strain level. Also,

unloading/reloading is taken into account with a user specified

constant ratio between loading/unloading stiffness. The model is

specifically designed for the use of isotropic compression tests,

but the results of an oedometer can be converted to fit the input

parameters. Very specific to this model is that a table of values

serves as input, and the model interpolates linearly between

these values. As a result, the (converted) oedometric test results

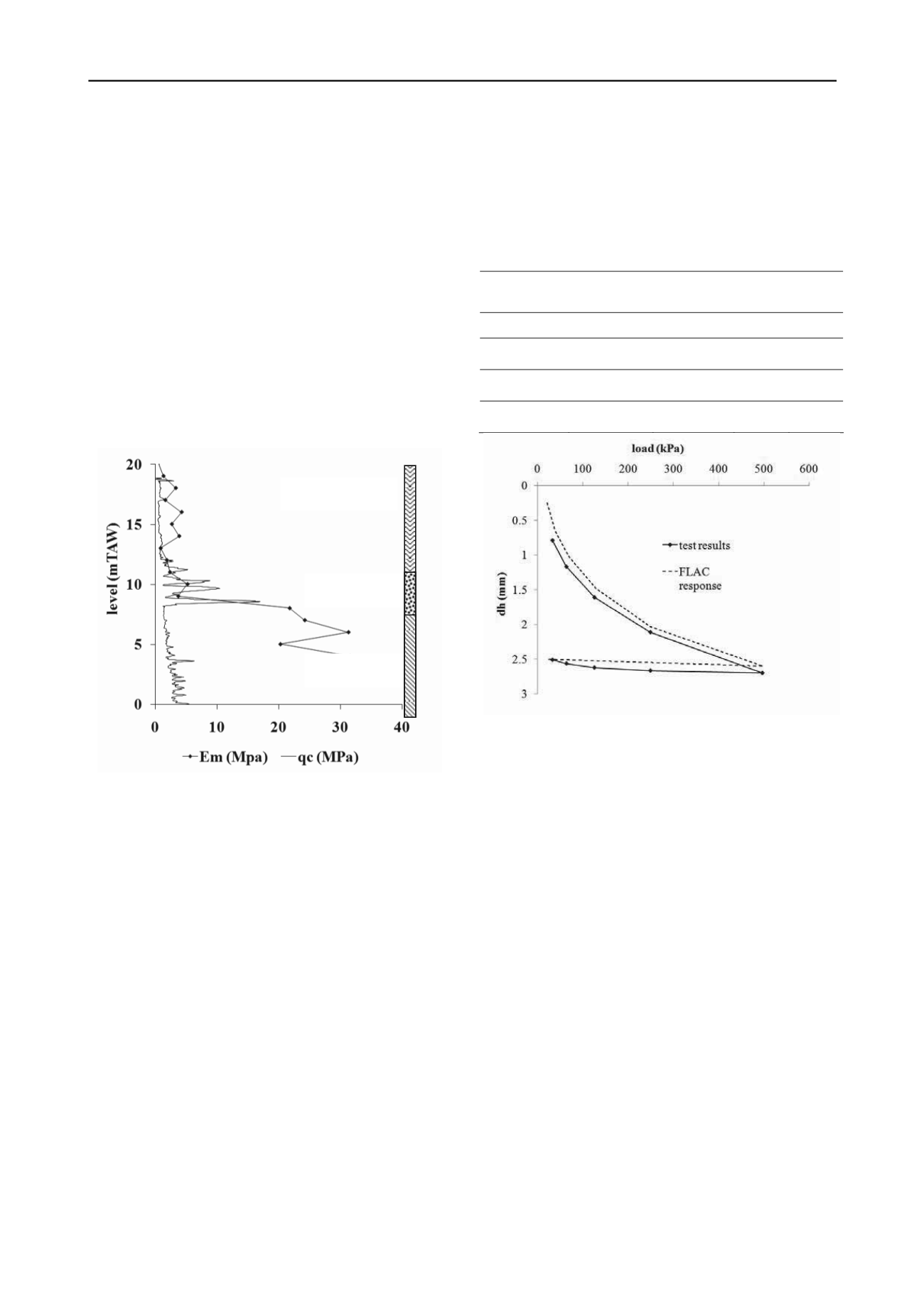

can serve as direct input. To check the model, a separate load

test model was used to check the input versus the modelling

results (Figure 3). Since it is very difficult to combine the

results of different oedometer tests, one representative

oedometer was chosen as single input.

Table 1. Soil parameters.

Parameter

alluvium

gravel

Yc

clay

fill

coh. (kPa)

5

0

20

4

friction (°)

22

32

25

27

E

M

(MPa)

2.5

10

27

/

p

l

(MPa)

0.5

1.9

1.6

/

Alluvial Clay

Gravel Layer

Yperian Clay

Figure 3. Comparison of model response with data from reference

oedometer test.

The jet grout wall was modelled as a continuous wall with

interface friction angle δ equal to the internal friction angle of

the surrounding soil, and with the stiffness and strength of only

the beam reinforcement of the jet grout piles. The wall is

stabilized with jet grout soil nails, which are modelled as pile

elements (with tensile and flexural strength) with an interface

cohesion (cu = qsu based on literature values).

To limit excessive swelling of the embankment, a simple

double yield model was used with constant loading and

reloading moduli.

3.3

Calculation results

The model showed that it was necessary to install the VHP

jetgrout piles till the depth of the base gravel. Otherwise,

vertical settlement of the wall would reverse wall interface

friction and would lead to excessive horizontal displacement.

Also, squeezing of the alluvium would occur when the

embedded length is further reduced.

Table 2 summarizes some results of the design calculations.

4 EXECUTION

The Berliner wall was placed with an excavator mounted

vibratory pile driver and anchored to an opposing Berliner wall

with tiebacks between the rail sleepers as shown in figure 1.