665

Technical Committee 103 /

Comité technique 103

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

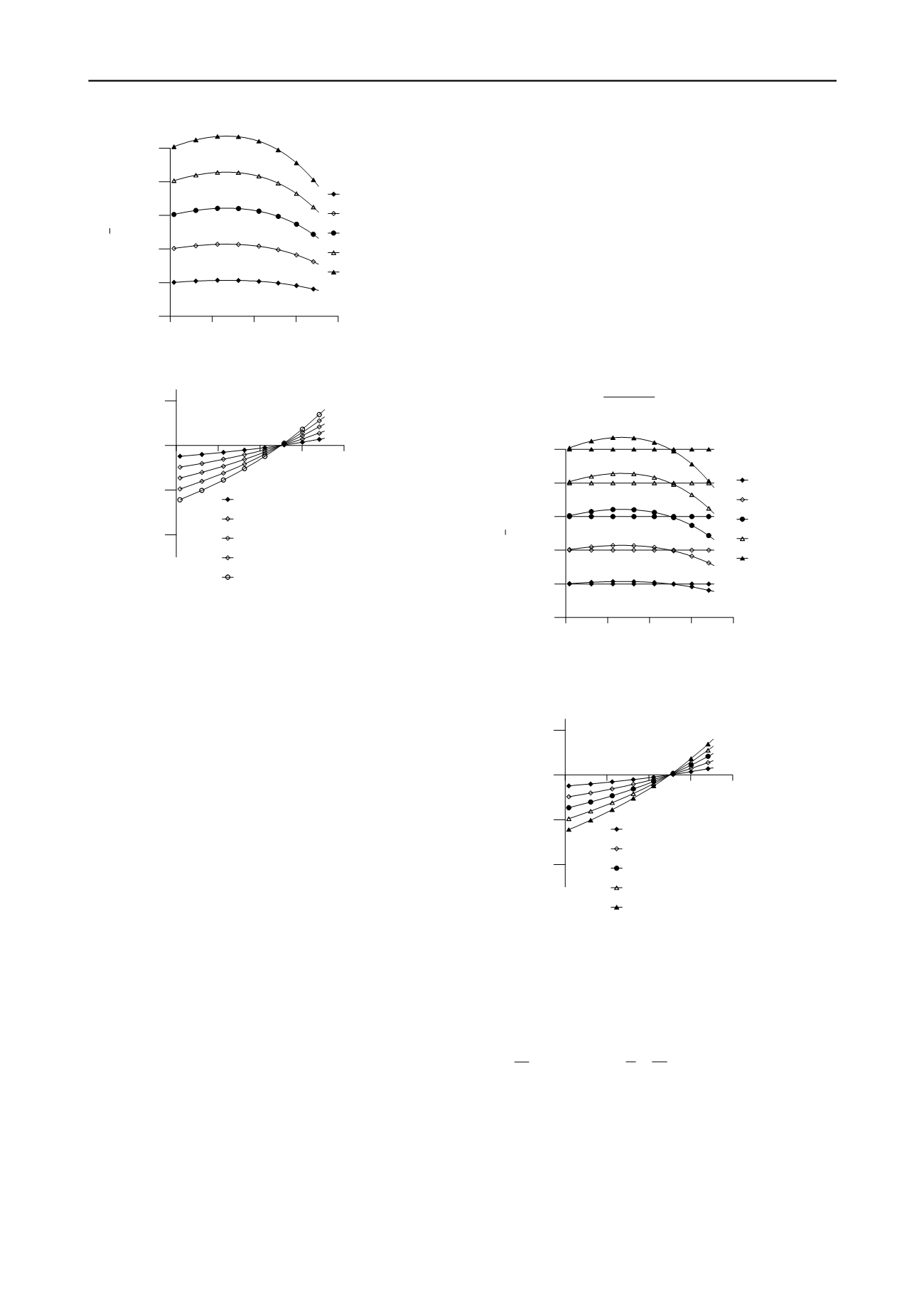

0 0.2 0.4 0.6 0.8

sin

m

0

0.1

0.2

0.3

0.4

0.5

D

p

/p

p

c=0.2

c=0.4

c=0.6

c=0.8

c=1

a

0 0.2 0.4 0.6 0.8

sin

m

-0.8

-0.4

0

0.4

f

c=0.2

c=0.4

c=0.6

c=0.8

c=1

a

Figure 2: a) Normalized plastic dissipation rate according to the

modified plastic dissipation in Eq. versus mobilized friction angle for

different degrees of non-coaxiality

0

30

c

j

=

; b) Plots of dilatancy ratio

versus stress ratio for different degrees of non-coaxiality, for Eq.

2.3 Proposal of a possible reconciliation

The two approaches, as demonstrated for plane strain

deformation mode, are not consistent with each other. The

selection of one over the other may require experimental

evidences. The authors do not come across sufficient

experimental data to clearly choose one over the other. It is,

however, self evident that both cannot hold to describe the same

phenomenon. The authors propose an alternative work

hypothesis,

s

m

p

p

M

cv q

pc M

e

D

=

,

(16)

such that the difference is reconciled.

There are other ways by which Eq.(16) can be obtained,

which shall not be discussed here. The resulting stress-dilatancy

equation now becomes

(

)

s

m

cv

M c M M

y

s

D

= -

.

(17)

For plane strain deformation mode, Eq. (17) simplifies to

(

)

ˆ sin

sin sin

m

c

m

c

y

j j

D

=- -

.

(18)

The hypotheses put forward by Gutierrez and Ishihara (2000)

and Gutierrez and Wang (2009), amplify the differences

between Taylor’s work hypothesis and Rowe’s minimum

energy hypothesis. However, in the modification proposed here

the difference between Eq.(10) and Eq. (18) is the same as that

of the stress-dilatancy relationship from Taylor’s work

hypothesis and Rowe’s minimum energy ratio hypothesis

(Figure 3).

Note that although for the sake of simplicity a constant

degree of non-coaxiality is used here; various experimental

results demonstrate that the degree of non-coaxiality is an

evolving state variable. Thornton and Zhang (2006) from their

DEM simulations pointed out that “at any stage of shearing,

during simple shear deformation, the angle of non-coaxiality

depends on the mobilized angle of shearing resistance, the rate

of dilation, the initial stress state, and the applied loading path”.

Post bifurcation evolution tendency of degree of non-coaxiality

is controversial. For example, the tests by Vardoulakis and

Georgopoulos (2004) show that degree of non-coaxiality

vanishes even during post bifurcation deformation whereas

Gutierrez and Vardoulakis (2007) show that degree of non-

coaxiality increases during post bifurcation deformation

The authors find a semi-empirical equation for evolution of

degree of non-coaxiality with stress ratio, for plane strain

deformation mode, as

(

)

1

2

1

R

N

c

c

c

N

C N

s

s

d

p

d

D

D

D D

=

-

+

,

(19)

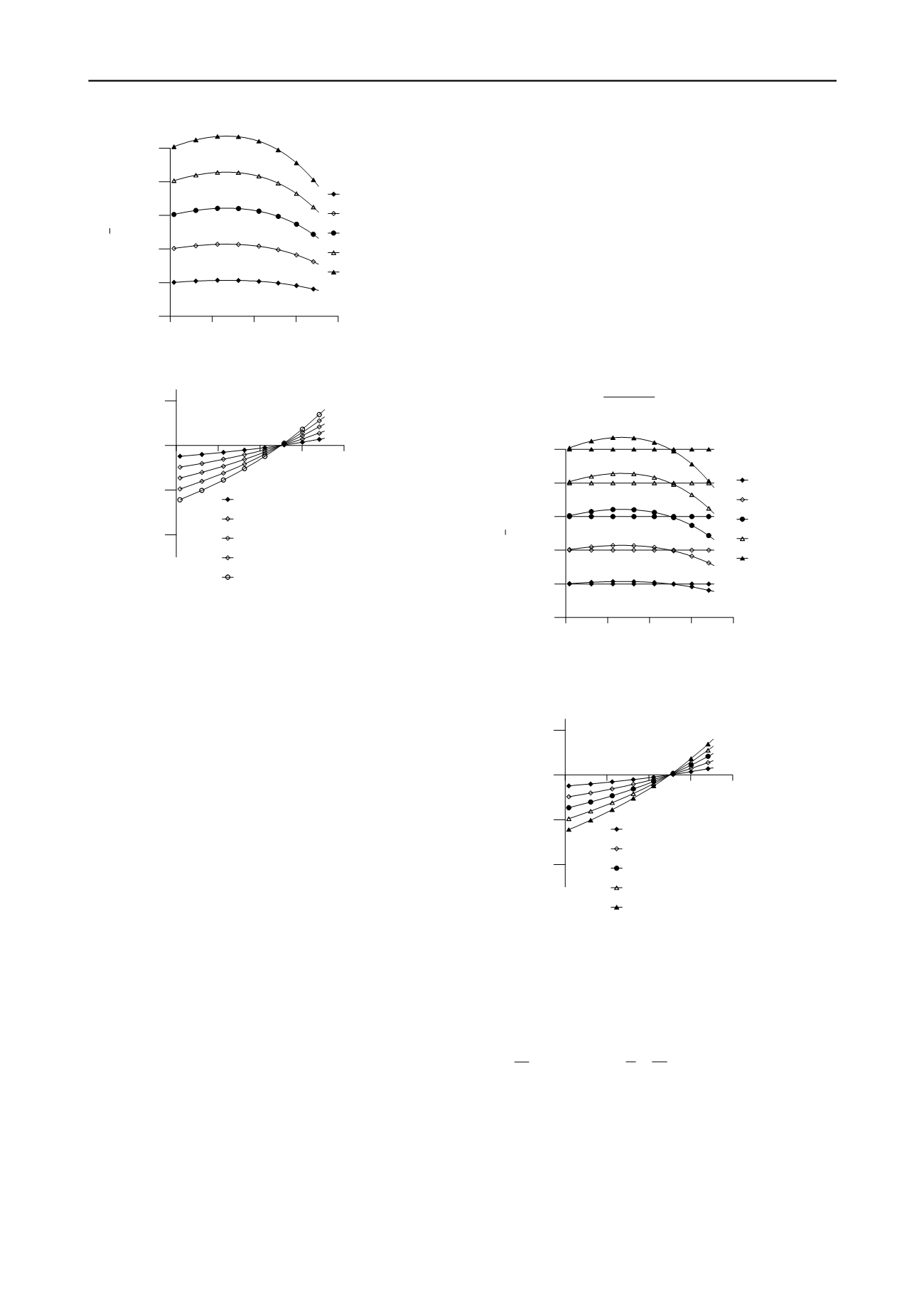

0 0.2 0.4 0.6 0.8

sin

m

0

0.1

0.2

0.3

0.4

0.5

D

p

/p

p

c=0.2

c=0.4

c=0.6

c=0.8

c=1

a

0 0.2 0.4 0.6 0.8

sin

m

-0.8

-0.4

0

0.4

-

sin

m

c=0.2

c=0.4

c=0.6

c=0.8

c=1

a

Figure 3: a) Normalized plastic dissipation rate according to the

modified plastic dissipation in Eq. versus mobilized friction angle for

different degrees of non-coaxiality

0

30

c

j

=

; b) Plots of dilatancy ratio

versus stress ratio for different degrees of non-coaxiality, for Eq.(18)

where

1

3

N

s

s

s

=

and

2

tan

4 2

c

N

C

p j

æ

ö÷

ç

= + ÷

ç

÷÷

çè

ø

(20)

and

R

D

is a parameter that controls the rate at which the initial

degree of non-coaxiality vanishes with stress ratio, Figure 4.

The equation implies that non-coaxiality vanishes with stress

ratio and increases when

0

N

s

d

<

. See for example Roscoe

(1970), Arthur

et al.

(1986) for experimental justification.

b

b