497

Technical Committee 102 /

Comité technique 102

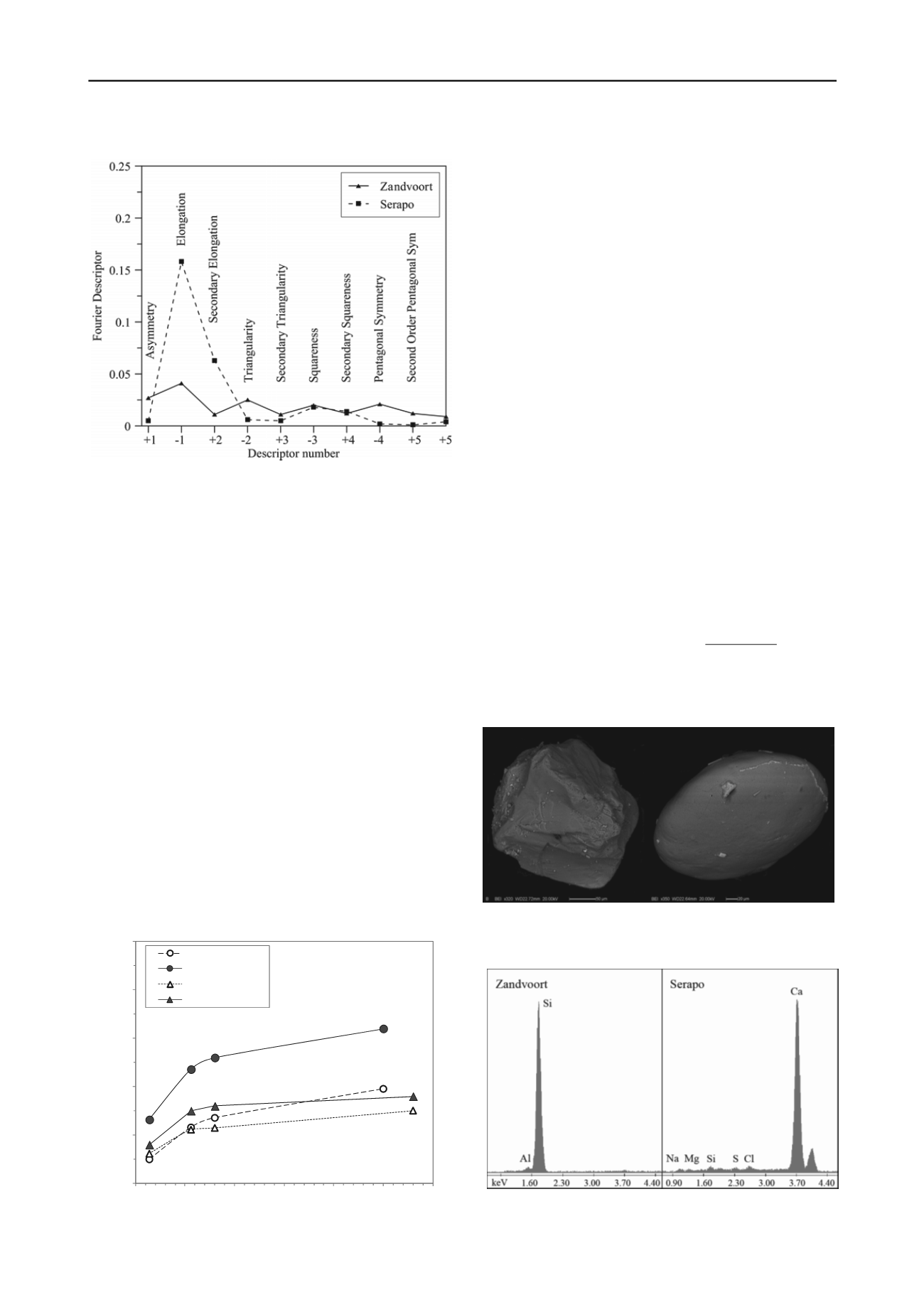

Figure 3.

From this figure it clearly appears that higher strength was

provided by the tests carried out on the SWGS, for which UCS

has been found to range between 12 and 16 MPa at 40 curing

days.

UCS obtained from the LS is lower at any curing time

investigated. In particular the UCS was found to be about 7.0

MPa at 40 curing days.

From the same figure, it also appears that UCS of LWGS

approaches the field values.

These results underlines the effectiveness of the

experimental set up in simulating the real field conditions, and

emphasizes the significant effect of drainage conditions, which

increase the UCS of about 1,9 times at 40 curing day.

To evaluate the influence of the type of sand, and, therefore,

of the related drainage effect on strength properties, the same

experimental procedure for sample preparation was replicated

on Serapo sand.

The results of Figure 4 confirm also for this kind of sand an

increment, even though less significant, of the UCS due to the

drainage effect. The increment was about 40% at 40 curing days

for the LWGS specimens with respect to the classical LS.

It is important to note (Figure 4) that similar UCS at 40

curing days was obtained from the LS of both Zandvoort and

Serapo sands (prepared according to JGS0821-2000). This was

expected since the two sands presents similar grain size

distributions.

The results obtained from the newly developed experimental

apparatus show that the type of sand and the corresponding

water drainage effect may greatly influence the mechanical

properties of the stabilized sandy soils.

0

5

10

15

20

25

0

25

50

75

100

125

15

Unconfined compressive strength, UCS (Mpa)

Curing time, t

cur

(days)

To investigate in more details the reason of this particular

outcome, mineralogical and microstructural tests were

performed on the two types of sand.

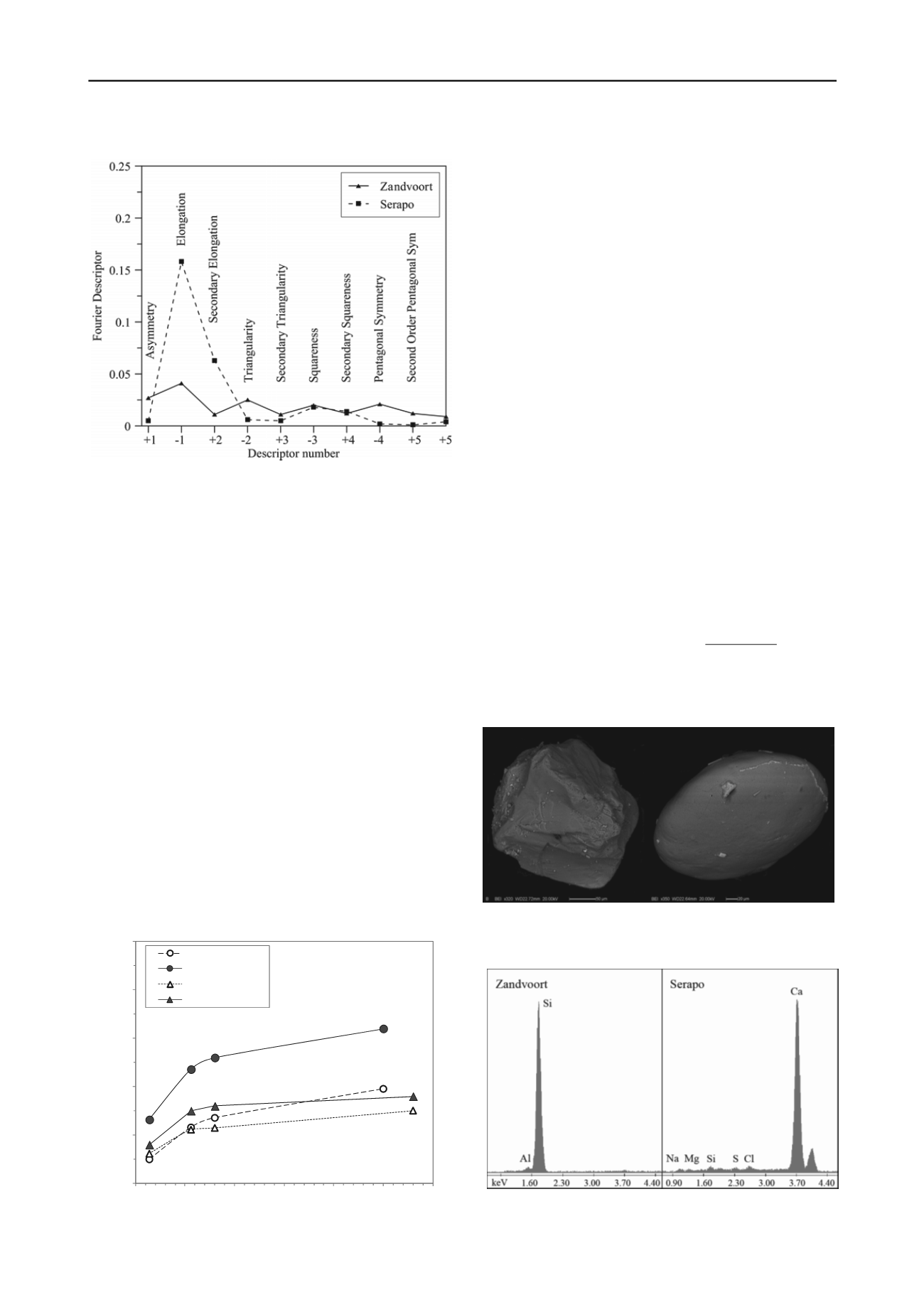

The SEM and EDS analyses results are shown in Figure 5

and 6.

Figure 5 presents two backscattered electron (BE) images of

two different sand grains: the grain on the left referring to

Zandvoort

sand, whereas that on the right to Serapo

sand.

Generally, both sands are predominantly composed of quartz

minerals, but in the Serapo sand a significant portion of

carbonate particles is present (Figure 6).

In addition, it is easily detectable the more irregular and

angular morphology of quartz grains of Zandvoort sand with

respect to the more rounded, sub-angular carbonate grain of

Serapo sand.

To quantify the degree of angularity different methods have

been proposed in the literature (de Santiago et al., 2008).

Among them, the procedure based on the Fourier descriptors

(Bowman et al, 2001) is one of the most diffuse recent

approaches.

0

SWGS Zandvoort

LS Zandvoort

LWGS Zandvoort

Figure 3. UC test results on Zandvoort sand specimens

i r 7. Lower order Fourier Descriptors obtained from the two

types of sands.

The boundary of the particle is circumnavigated in the

complex plane at a constant speed. The step size is selected so

that the circumnavigation takes 2π and the number of steps is

2

k

. The complex function presented in Eq. (1) allows to

determine the aforementioned Fourier descriptors

2/

12/

2

exp

N

N n

n

m m

M

mn i

Z

yi

x

(1)

where

x

,

y

are the coordinates of the particle boundary,

N

is the

Figure 5.

Comparison between SE images of a Zandvoort (on the left)

and Serapo sand grain (on the right)

Figure 6.

Chemical compositions from EDS analysis performed on a

Zandvoort (on the left) and a Serapo sand grains (on the right).

0

5

10

15

20

25

0

25

50

75

100

125

15

Unconfined compressive strength, UCS (Mpa)

Curing time, t

cur

(days)

0

LS Zandvoort

LWGS Zandvoort

LS Serapo

LWGS Serapo

Figure 4. UC test results on Zandvoort and Serapo specimens