496

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

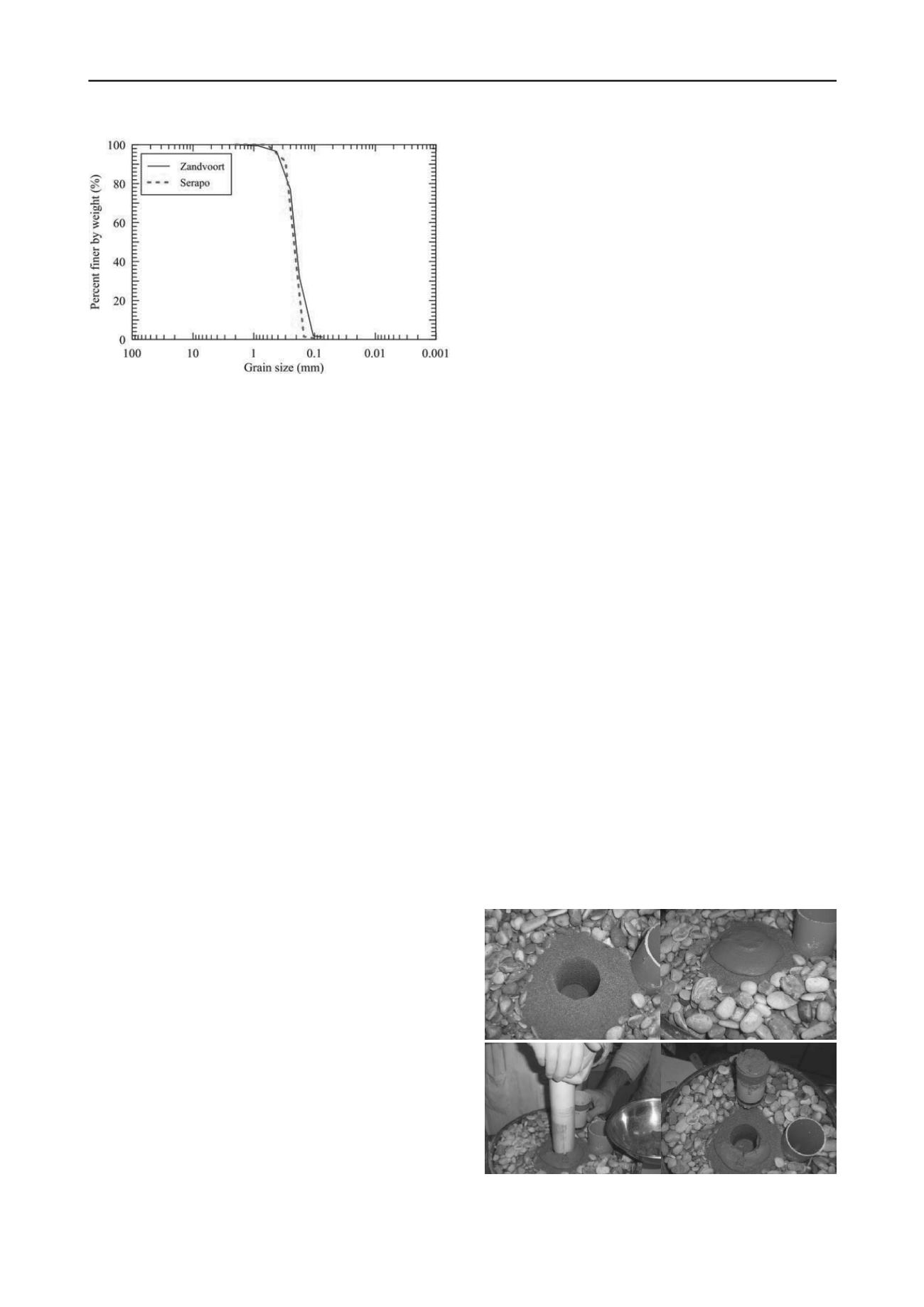

Figure 1. Grain size distribution of the Zandvoort and Serapo sands .

To construct the 11.5 m deep CSM panels (2.4 x 0.55 = 1.32

m

2

sectional area) the 1-Phase system was chosen, therefore the

grout was injected on both downward and upward stroke. The

grout composition adopted for the panel production was

characterized by a water-to-cement ratio

w/c

= 1.12 and a binder

factor

α

= 509 kg/m

3

of natural soil. The cement used was a

special composite cement especially produced for ground

improvement applications.

After mixing, several wet-grab samples were collected from

the fresh panels at about 2,0 m from the ground level and

immediately sealed into watertight tins (inner diameter of 98

mm and height of 113 mm).

3 MATERIALS AND TESTING PROGRAMME

The

wet-grab

samples collected from the site (in the following

referred as “SWGS”) were cured under controlled condition

(room temperature of about 20°C and at a relative humidity >

95%.) for 40 and 125 days in order to measure also the time

influence on the unconfined compressive strength (UCS) of the

treated soil. Before testing, the wet-grab samples were cored to

provide specimens of 37 and 54 mm in diameter with an aspect

ratio of 2. Finally, the specimens were trimmed to regularize the

bases and wrapped with plastic film to prevent moisture loss.

Laboratory soil-binder mixtures were prepared at the same

grout/sand ratio used on site, according to the treatment

parameters evaluated from the elaborated machine production

data. The grout and the soil were first prepared separately and

then mixed together for 10 minutes using a high power mixer to

produce the stabilized soil, according to the recommendations

for laboratory mixed specimens provided by the Japanese

Geotechnical Society (JGS0821-2000).

The stabilized soil was then poured into plastic moulds 50

mm in diameter and 100 mm in height using the No

Compaction technique (simply consisted in filling the mold) to

realize the

laboratory mixed specimens

(referred as “LS”).

Past experiences of sandy soil stabilization (Yoshimura et al,

2009, Grisolia et al, 2010, Bellato et al., 2012) showed the

following occurrences related to water drainage conditions:

The physical properties (water content and wet density)

of sandy soil collected from the site, especially when taken

below the groundwater table, typically are different from the

initial in-situ conditions, due to the loss of fine particles and

water during sampling and transportation to the laboratory;

Bleeding, i.e. separation of water from the soil-binder

mixture, generally occurs immediately after the mixing

process in the bowl and causes the sedimentation of some

amount of cement at the surface;

Every molded sample usually shows the occurrence of

bleeding phenomena, that inevitably leads to a reduction in

the specimen’s height;

In addition, when the mixture is taken from the bowl for

molding operations, separation among constituent materials

may be observed. This further increases the variability in

terms of amounts of binder, water and sand of the samples.

Moreover, during in-situ soil treatments, some water

drainage may also arise depending on the type of mixing

procedure adopted and the specific subsoil conditions. In

particular, sedimentation mechanisms in the liquid soil-binder

slurry mixture may develop just after the passage of the

mixing tools and some amount of water can be radially

drained away into the surrounding permeable sandy layers

(Yoshimura et al, 2009).

To simulate the effects of water drainage on the mechanical

properties of stabilized soils in the laboratory an original

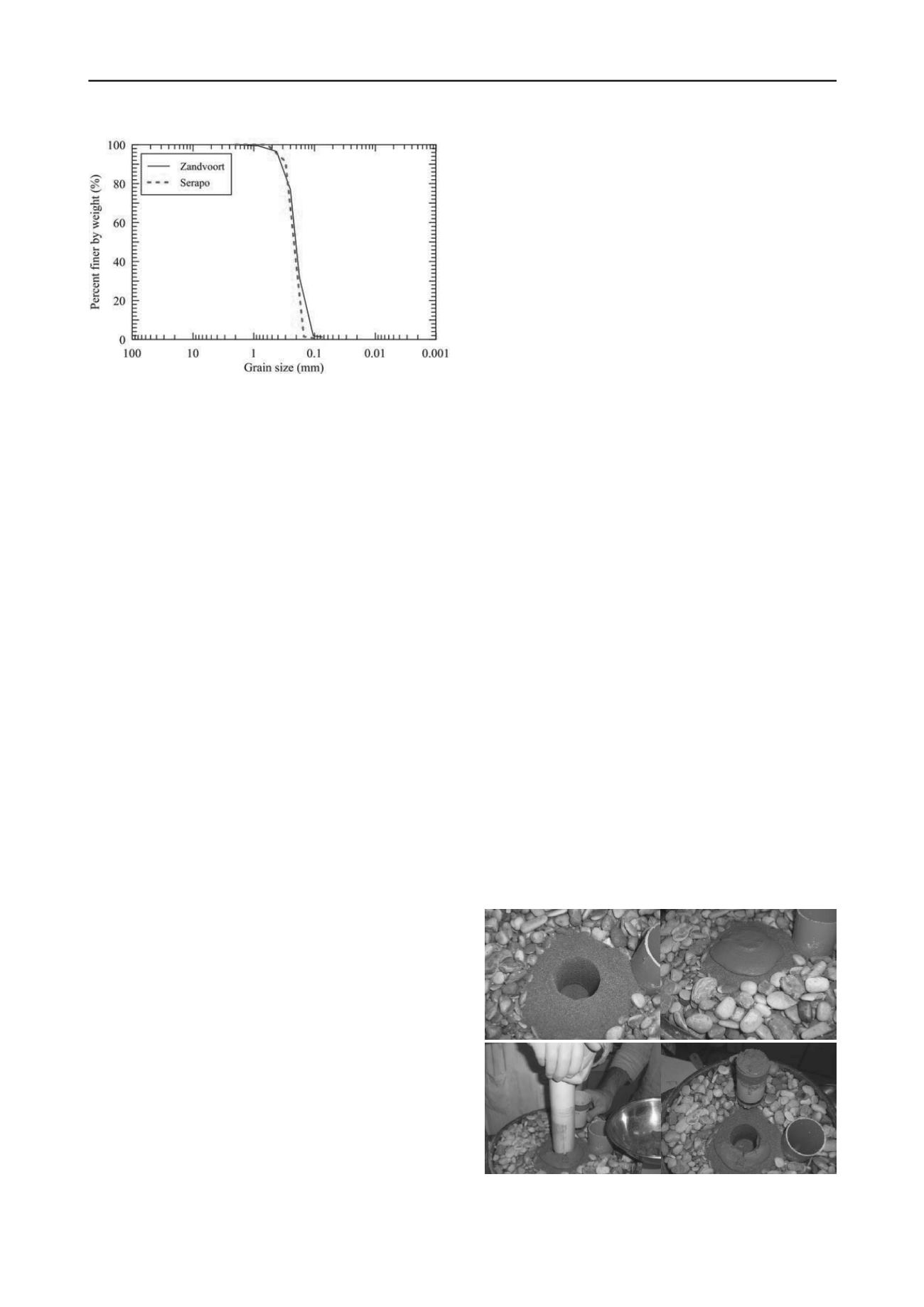

experimental set up was designed and used (Figure 2).

The apparatus was essentially composed of a watertight

container in which a cylindrical sand core, reproducing the site

conditions, is placed and surrounded by a gravel filter, with

installed an open pipe for water level control (Figure 2a).

A cylindrical cavity was then prepared and filled with the

stabilized soil just after the mixing operations (Figure 2b). After

a time span equal to that adopted on site before sampling, a

laboratory wet-grab specimen was retrieved (Figure 2c and 2d).

The two types of specimens, i.e. laboratory (“LS”) and

laboratory wet-grab

(“LWGS”), were cured at 20°C and at 95%

relative humidity in curing tanks and removed from the moulds

just before the test.

In order to investigate the influence of the sand type and

mineralogy on the performance of the stabilized material, a

marine soil namely Serapo Sand (Figure 1) was also used to

prepare laboratory and laboratory wet-grab specimens.

The experimental investigation mainly consisted of

unconfined compression tests. The specimens were tested at

different curing times, ranging from 7 to 125 days.

To evaluate the influence of the physical and chemical

characteristics of the natural soils (Zandvoort and Serapo sands)

SEM (Scanning Electron Microscope) and EDS (Energy

Dispersive Spectroscopy) analysis were carried out.

A CamScan MX2500 electron microscope, equipped with a

EDAX EDS (energy dispersive X-ray spectrometer) system was

used to determine both the morphology and chemical

composition of the grains. Two small samples for both sands

were first oven dried at 40°C for 24 h and then coated with a

layer of carbon using an high-vacuum evaporative coater to

prevent the accumulation of electrostatic charges at the surface

during irradiation.

4 RESULTS AND DISCUSSION

The results of the unconfined compression tests performed on

the three series of samples (SWGS, LS, LWGS) are presented in

Figure 2. Experimental set-up for laboratory wet grab specimens: a)

cavity preparation, b) mixture pouring, c,d) specimen retrieval.