442

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Plasticity). Note that the as-sampled moisture state was drier

than the Plastic limit. In the as-sampled moisture state, the -

2.36 mm scalped sample had a total suction, measured using a

WP4 Dewpoint Potential Meter, of 4,320 kPa. The specific

gravity of the solids, measured using a helium pcynometer, was

2.60.

The electrical conductivity (EC) and pH of a 5 (deionised

water) to 1 (-2.36 mm scalped, dry solids) paste of Jeebropilly

weathered rock were 356 µS/cm and 4.0, respectively. From the

measured EC, corrected to 25

o

C, and the relationship between

EC and osmotic suction (after U.S.D.A. 1954), an as-sampled

osmotic suction of 10 kPa was obtained, and a matric suction of

4,310 kPa was obtained by subtraction from the measured total

suction. The Emerson Class Number of the Jeebropilly

weathered rock was 1, implying that the material slakes and

disperses completely, and had a high potential for breakdown

and erosion.

Mg

2+

is the dominant cation in the Jeebropilly weathered

rock, and its high cation exchange capacity (CEC) of

16 cmol(+)/kg and sodium adsorption ratio (SAR) of 0.76

suggest a relatively high clay content, low permeability, limited

structure, the potential for compaction under trafficking, and the

potential for internal erosion.

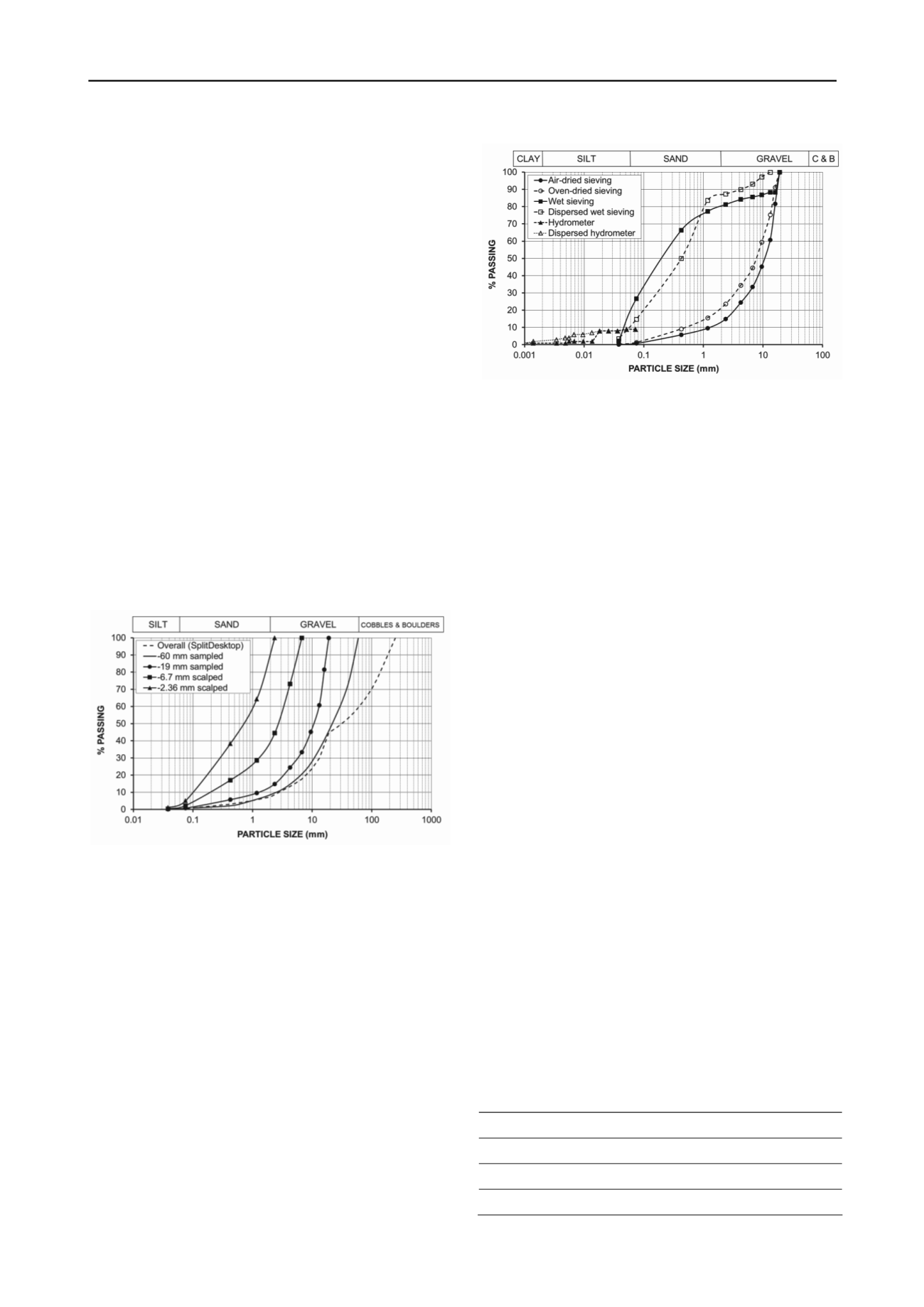

The particle size distribution curves obtained from

photographs using SplitDesktop (

-

desktop/) or by dry sieving after air-drying of the -19 mm

scalped Jeebropilly weathered rock are shown in Figure 1,

together with the scalped curves obtained by the removal of the

oversize, for use in the various laboratory tests.

Figure 1. Particle size distribution curves of Jeebropilly weathered rock

overall, and scalped for use in various laboratory tests.

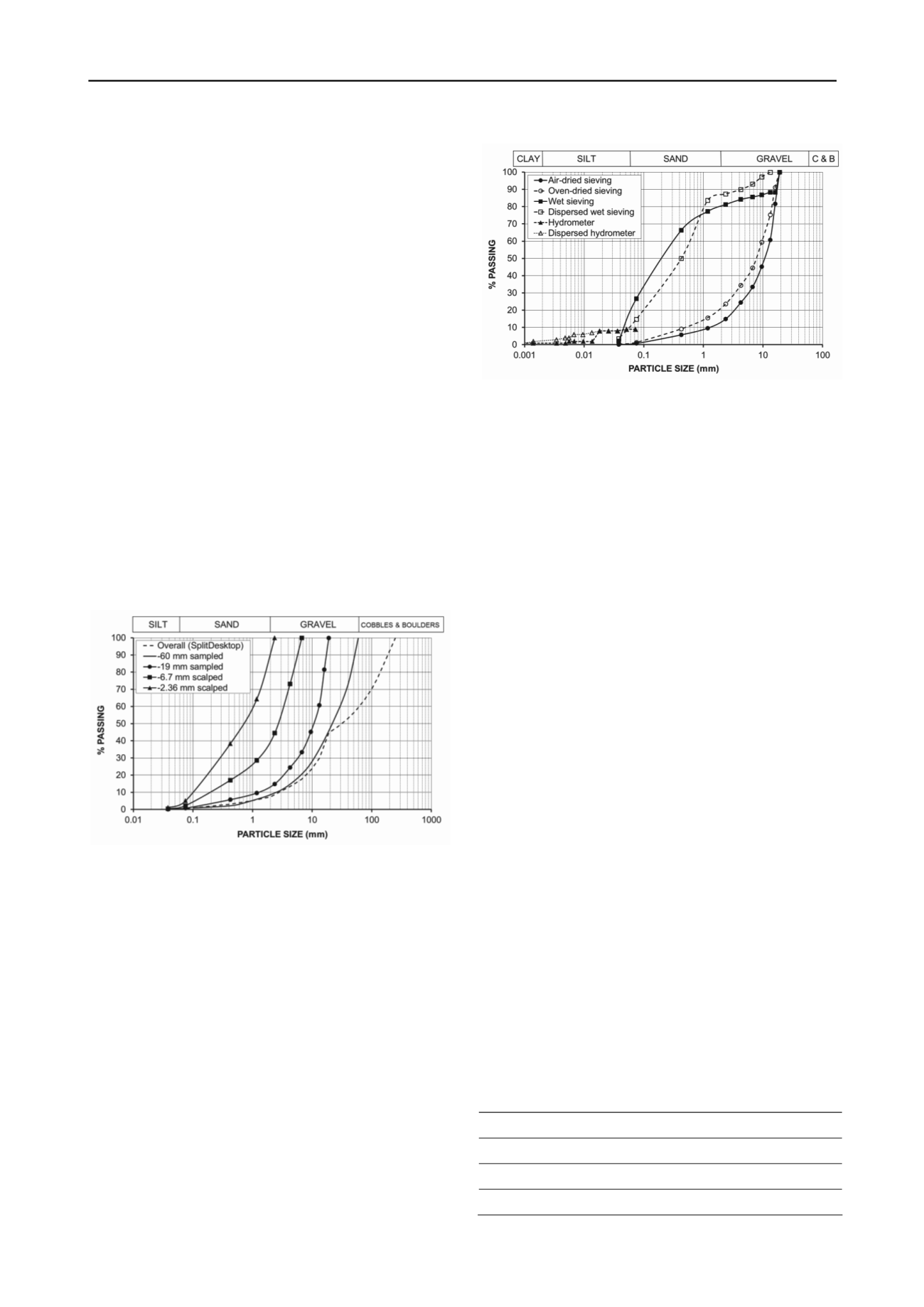

The particle size distribution curves obtained for the -19 mm

scalped Jeebropilly weathered rock by dry sieving after air-

drying or 60

o

C oven-drying, by wet sieving using tap water

without or with dispersant added, and by hydrometer analysis in

deionised water without or with dispersant added, are shown in

Figure 2.

It is clear from Figure 2 that Jeebropilly weathered rock is

extremely prone to breakdown in the presence of water,

dominated by the gravel fraction breaking down to sand-size,

with no appreciable generation of silt and clay fines. The results

of the hydrometer analyses suggest that the fines content is less

than 10% by mass, and that the clay content is negligible.

However, it is likely that the intrinsic particle size does contain

appreciable silt and clay fines, and that these would require

more energy to be released than is applied in the standard test

procedure. The effect of adding dispersant is minor.

Laboratory Standard compaction testing of -19 mm scalped

Jeebropilly weathered rock indicated a low Maximum Dry

Density (MDD) of only 1.52 t/m

3

, at an Optimum (gravimetric)

Moisture Content (OMC) of 19.0%, close to the Plastic Limit of

the material. At the MDD and OMC, the material has a high

porosity of 0.42 and a low degree of saturation of 69%.

Figure 2. Particle size distribution curves of -19 mm scalped Jeebropilly

weathered rock obtained with different pre-treatments and testing

methods.

4 SHEAR STRENGTH

Shear strength testing of loosely-placed, -2.36 mm scalped

Jeebropilly weathered rock, at its as-sampled gravimetric

moisture content of 14.8% (that is, tested “dry”) or tested in a

water bath (that is, tested “wet”), was carried out in a 60 mm

direct shear box. It demonstrated that the shear strength

envelopes obtained were not substantially dependent on the

shearing rate over the range from 0.01 mm/min to 1 mm/min;

implying that drained conditions existed over this range.

On testing dry, the loose-placed dry density of the

Jeebropilly weathered rock averaged 0.908 t/m

3

. This increased

to an average 1.226 t/m

3

after 24-hour compression under a

normal stress of 500 kPa, and to an average 1.370 t/m

3

(75% of

MDD) after shearing. Compression increased the average

degree of saturation from the loose-placed value of 20.7 to

34.4% and 36.9% after shearing, as the average porosity

decreased from 0.650, to 0.528 to 0.510, respectively.

On testing wet, the loose-placed dry density of the

Jeebropilly weathered rock averaged 0.991 t/m

3

. This increased

to an average 1.351 t/m

3

after 24-hour compression under a

normal stress of 150 kPa, and to an average 1.445 t/m

3

(82% of

MDD) after shearing. Compression decreased the average

gravimetric moisture content from the loose-placed value of

70.4 to 35.5% and 34.3% after shearing, as the average porosity

decreased from 0.647, to 0.480 to 0.471, respectively.

The shear strength parameters obtained for -2.36 mm scalped

Jeebropilly weathered rock are summarised in Table 1, in terms

of apparent cohesion and friction angle, and friction angle only

(assuming zero cohesion). These values are in broad agreement

with those recommended for comparable coal mine spoil

materials (Simmons 1995).

Shear strength testing of -2.36 mm scalped Jeebropilly

weathered rock was also carried out in a 300 mm direct shear

box at a shearing rate of 1 mm/min. The shear strengths

obtained from the 60 mm and 300 mm direct shear box testing

at a shearing rate of 1 mm/min are compared in Figure 3. The

results from the smaller shear box cover a far greater range

between dry and wet conditions than those from the 300 mm

shear box, and appear more plausible.

Table 1. Shear strength parameters for Jeebropilly weathered rock.

State

Dry

Wet

Apparent cohesion (kPa)

29

6.0

Apparent friction angle (deg.)

27.2

19.5

Friction only angle (deg.)

35.2

22.0