431

Technical Committee 101 - Session II /

Comité technique 101 - Session II

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

ratio it can be concluded that the cementation compounds are

still insufficient to bind the clay fabric in case of high W/C ratio

whereas at the lowest W/C ratio the cement matrix is

continuous binding the clay aggregates contributing to a

significant strength gain.

It can be seen from Figure 3 that the effect of curing is

almost negligible and this is mainly because the organics

tending to coat the surface of the soil particles impeding the

interaction between clay minerals and the cement hydration

products harming the long term strength gain contributed by

secondary reactions (Chen & Wang 2006). Results indicate that

for the same W/C ratio the variation in initial water content has

very little influence on the long term strength gain thus

confirming the critical role played by W/C ratio in strength

development of cemented clays as suggested by Miura et al.

(2001).

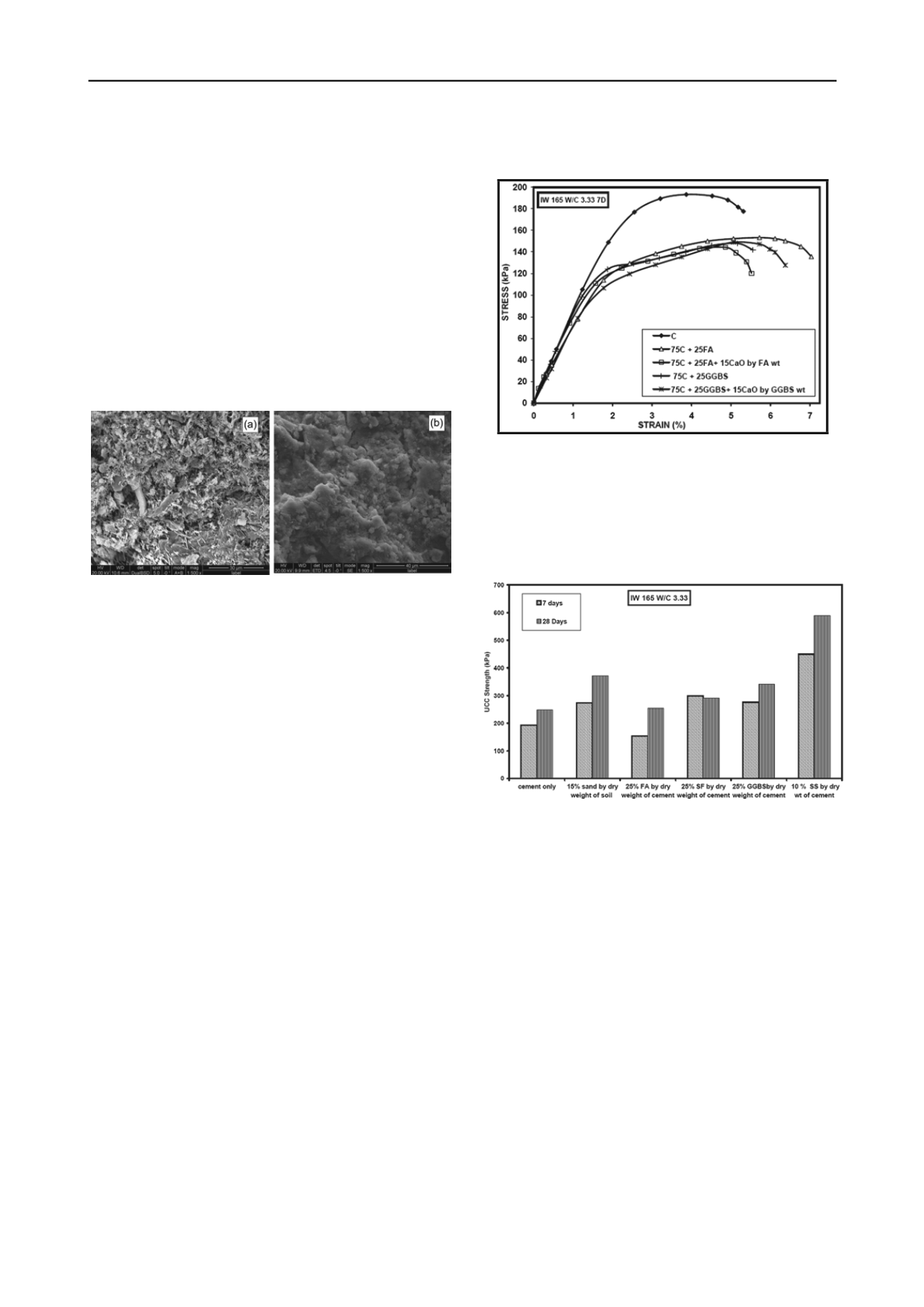

Figure 4. Fabric of Cemented Kuttanad clay (a) W/C 6.5 (b) W/C 3.33

3.2 Cement Composite binder combination

With an effort to economize and reduce the carbon foot print of

the proposed ground improvement technique, composite binder

combinations such as cement – Lime, Cement – FA and Cement

– GGBS were tried.

3.2.1 Cement-Lime

Quick lime as reported in literature (Åhnberg and Johansson

2005) as a possible replacement for cement was tried in

different proportion with cement and the UCC tests were done

on stabilized soil samples. For IW 165 % and W/C ratio 5,

Cement(C) - Quick Lime (L) binder combinations of 75C-25L

and 50C-50L were tried and the UCC strength at the end of 14

days curing was found. UCC strength of the sample with only

cement as binder was 99 kPa where as with lime replacement

the strengths significantly reduced to 33 kPa (75C-25L) and 25

kPa (50C-50L). Development of strength happens when the

added lime reacts with the clay minerals. As soon as lime is

added, pH increases and there is De-flocculation of soil fabric

and removal of organics adsorbed on to the minerals. The

organic matter hinders the reactions between added lime and the

clay minerals present in the soil hence there is no beneficial

effect of lime replacement observed. Diatom silica is also found

not reacting with the added lime confirming the role of

components such as organic content and sesquioxides (Van

Capellen et al. 2001) present in the soil inhibiting its solubility,

finally retarding the puzzolonic reactions responsible for

strength development.

3.2.2 Cement - Mineral admixtures

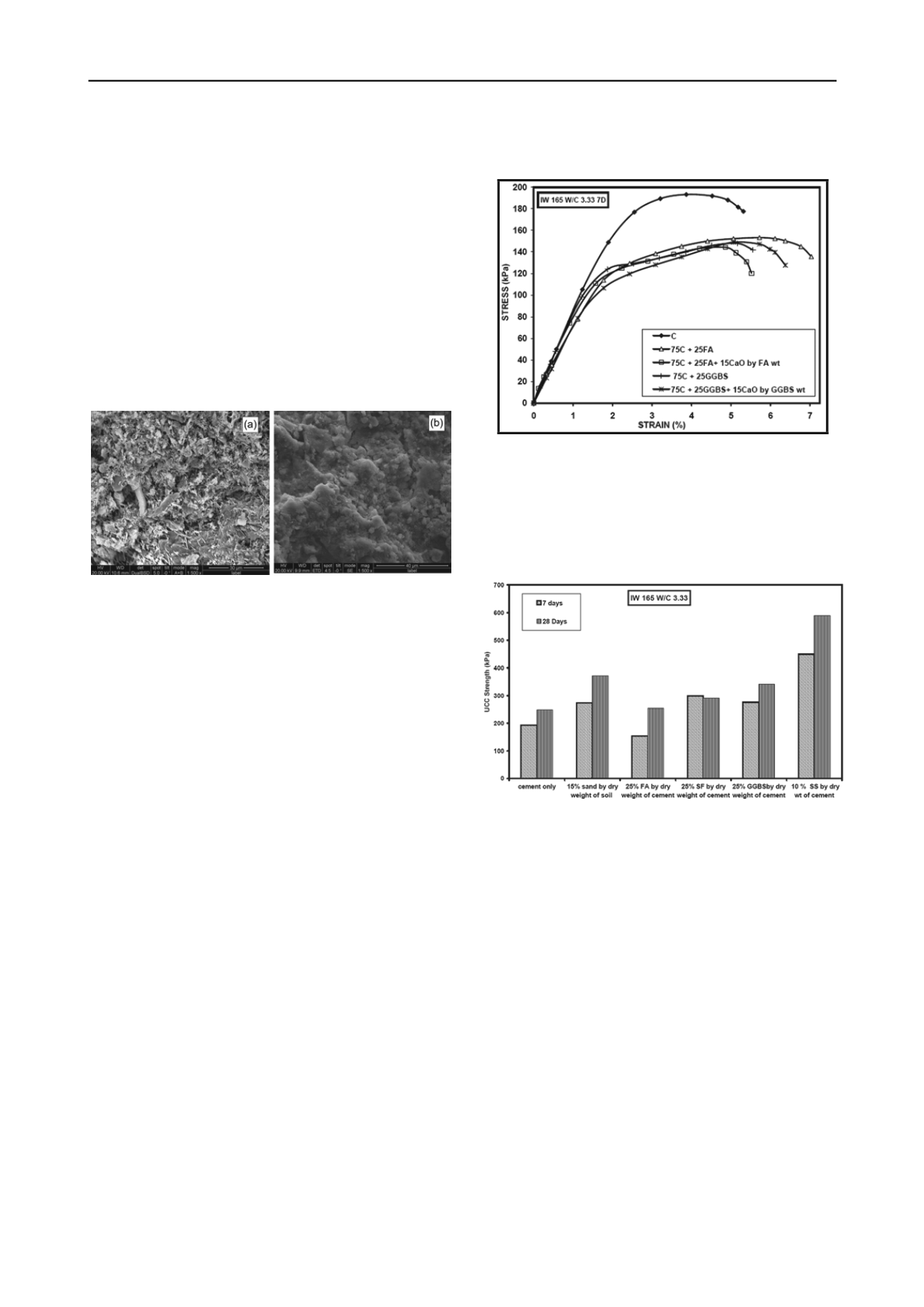

Figure 5, shows the stress – strain characteristics of cement with

GGBS and Fly ash binder combination with and with out lime.

It can be clearly seen that the effect of replacing a portion of

cement with either of the mineral admixtures (GGBS / FA)

results in strength loss when compared to the cement alone case.

Hence it reinforces the fact that the positive effect of puzzolonic

reactions is not enough to offset the role of cement which is

replaced. Both lime released and lime added have insignificant

role to play in enhancing the strength of the Cement - Mineral

admixture stabilized Kuttanad soil.

Figure 5. Stress Vs Strain for cement- mineral admixture combination

3.3 Role of Admixtures

To further enhance the strength of soil with cement as binder

different additives with varying reactive silica content were

considered. Results from UCC tests of different additives such

as Fine sand, Fly ash, Silica fume, GGBS and Sodium silicate

used along with cement are shown in Figure 6.

Figure 6. Effect of various additives on UCC strength of cemented soil

It is evident from Figure 6, that addition of fine sand to the

mix has enhanced the shear strength of the cement stabilized

soil. The mechanism of strength enhancement in this case can

be attributed to the matrix of cemented sand supporting the

weak soil within it. It is well known that the cement can bind

very effectively the coarser sand particles involving lesser

contact points than the fine organic soil.

The addition of fly ash resulting in no strength improvement

can also be due to the interaction of the strengthening matrix of

both soil cement and fly ash cement system leading to a weaker

framework.

Silica fume as an additive with cement resulted in 17 %

strength increment in case of 28 days cured samples (Figure 7).

The strength increment is marginal and can be attributed to the

participation of silica fume in the pozzolanic reactions,

involving lime liberated from cement hydrolysis.

Adding 25 % GGBS by weight of cement resulted in a

strength increase of about 37 % at the end of 28 days curing

(Figure 7). The strength increase is due to the formation of

cementation products because of the alkali activation of GGBS

caused by cement hydrolysis (Taylor 1997). GGBS is coarser

and accommodates soil in its matrix and the subsequent

production of cementitious products by itself results in effective

binding giving an enhanced strength.