430

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

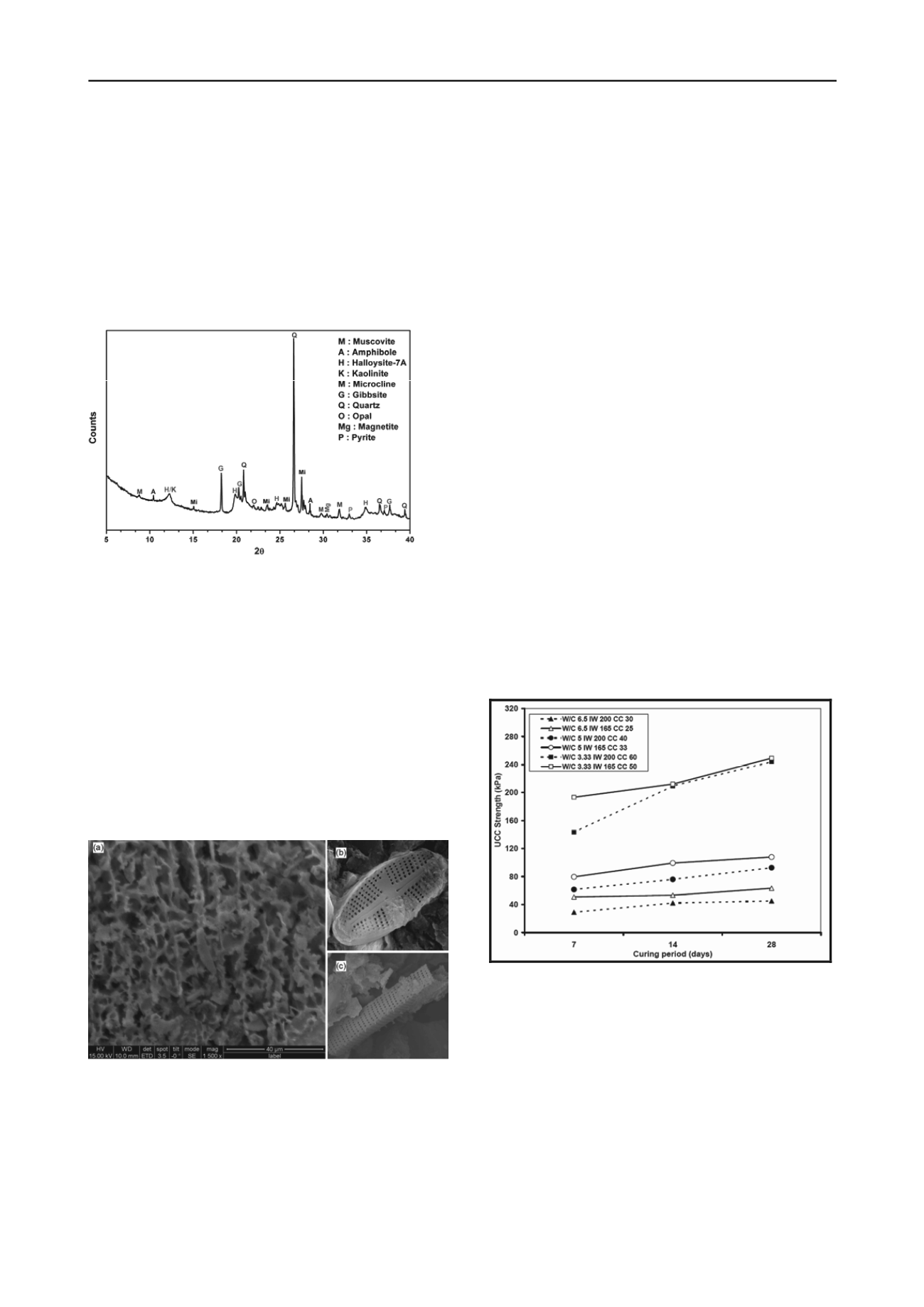

2.2 Soil Mineralogy

2.2.1 X-Ray Diffraction (XRD) Studies

XRD analysis was carried out using Bruker D8 Advance system

on powder samples. Samples were scanned using copper K

alpha (λ = 1.54 Å) radiation at a scanning rate of 1º/minute.

Identification of minerals was done by comparing the XRD

patterns got from the soil with the standard data sets of the

known minerals (JCPDF, Powder Diffraction File, 1990). The

peaks for the Kuttanad soil and its corresponding minerals are

shown in Fig. 1.

Figure 1. XRD of Kuttanad clay

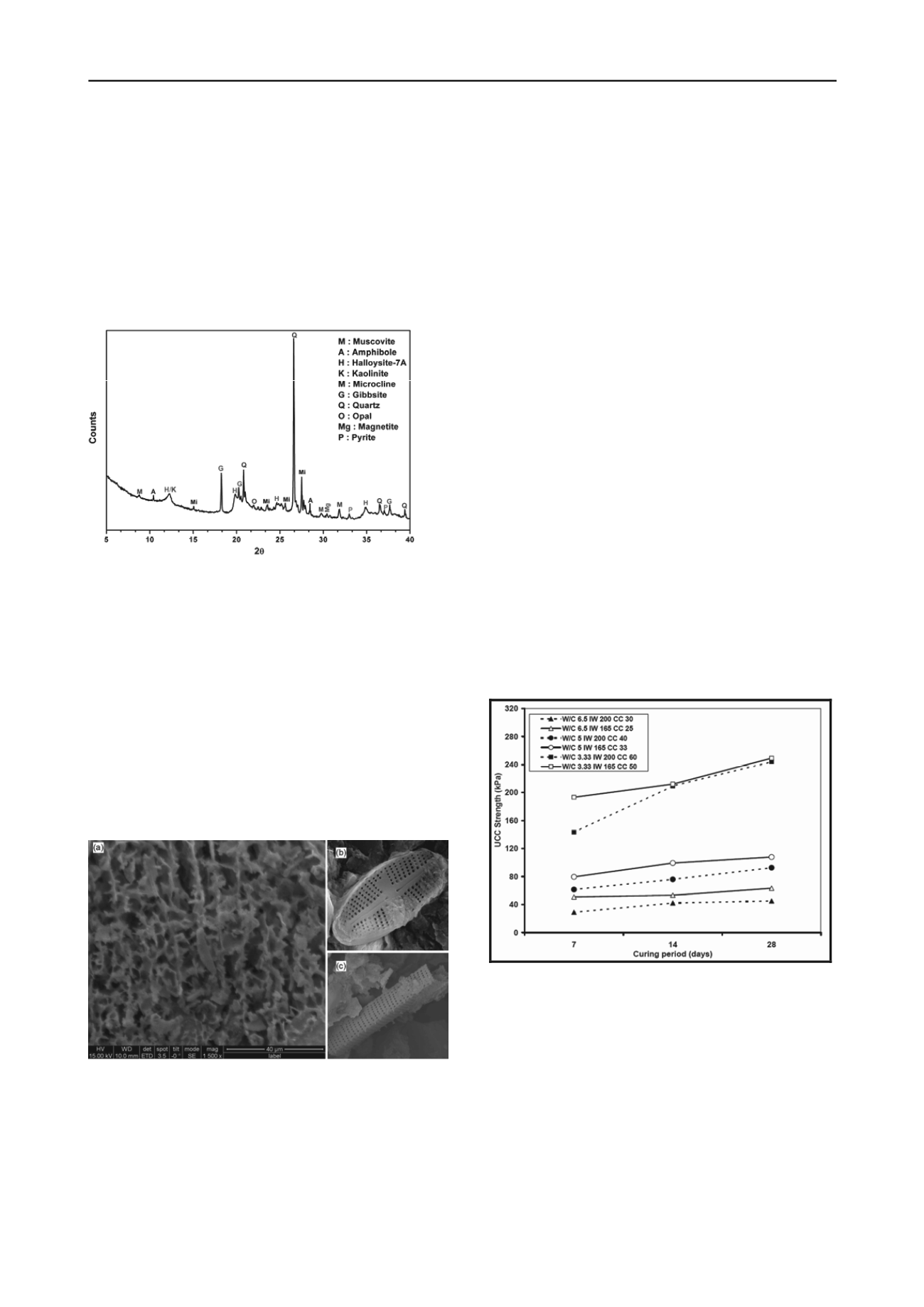

2.2.2 Scanning Electron Microscopy (SEM)

The Quanta Environmental Scanning Electron Microscope

(ESEM) was used in analyzing the fabric of the uncemented and

cemented clay. A study of the micrographs of uncemented

Kuttanad soil sample prepared by freeze drying technique

indicates an open honeycomb type of fabric arrangement, as

shown in Fig. 2(a). The fabric shows the presence of frustules,

Fig .2(b & c), which are skeletal remains of diatoms, composed

of amorphous silica (opal, presence also verified by XRD

analysis). Diatomaceous frustules in marine sediments are

known to play a significant role in controlling the geotechnical

properties of the soil (Rajasekaran 2006) and this study tries to

throw some light on the ability of this amorphous form of silica

to participate in the strengthening reactions with binders.

Figure 2. (a) Open fabric of Kuttanad marine clay and (b) & (c) Diatom

frustules in Kuttanad clay

2.3 Binders

In the current study ordinary Portland cement of 43 grade was

used as the binder. Initially the effect of cement stabilization

was evaluated by varying parameters such as IW, W/C and

curing period. And then the effect of different composite binder

combinations with mineral admixtures and puzzolonic materials

such as quick lime (CaO), Ground granulated blast furnace slag

(GGBS) and Fly ash (FA) on Kuttanad soil stabilization was

studied. Further for W/C ratio of 3.33 addition of FA, GGBS,

Silica fume (SF), Sodium Silicate (SS) and Fine sand to cement

on the strength of Kuttanad clay was evaluated.

2.4 Sample Preparation

The clay was thoroughly hand mixed and IW was increased to

165 % and 200 %. The intentional increase in the initial water

content before stabilizing was done to simulate the field

conditions where there is a raise in the insitu water content

because of wet binder dispensing methods adopted during deep

mixing (Horpibulsuk et al. 2004). Cement quantity to be added

for preparing the mixes was calculated based on W/C ratio. In

the present investigation three W/C ratios were used namely

6.5, 5 and 3.33. Cement was added to the soil and mixed

thoroughly for about 10 minutes as suggested by Miura et al.

2001. Split moulds having diameter 38 mm and height 76 mm

(Length/Diameter = 2) with sides slightly lubricated with oil

were used for casting and curing the stabilized mixes. The well

mixed paste was transferred to the split mould in three layers.

Spreading of the paste into the mould and removal of air

entrapped during casting was done by giving mild tamping for

each layer. The samples caste in the split moulds were cured for

7, 14 and 28 days in desiccators maintained at 100 % relative

humidity. Similar methodology of making samples was adopted

for different composite binder combinations adopted in this

study.

3 RESULTS AND DICUSSION

3.1 Cement as binder

Figure 3 presents the UCC strength of cement stabilized

samples at different W/C ratio with varying IW and Cement

Content (CC) with curing period.

Figure 3. Unconfined compressive strength (UCC) of cement stabilized

samples

It can be seen from Figure 3 that with reducing W/C ratio there

is an increase in the strength developed. Even though the

cement percentage corresponding to the W/C ratios used in the

study is high (more than 25 %) the strength attained is very low.

This might be due to the organic content present in the soil

hindering the cement hydrolysis and subsequent strength

development. It can also be inferred that up to W/C ratio of 5

there is a marginal improvement in the UCC strength but when

the W/C ratio further reduces to 3.33 the strength gained is

significant. This is because the organic components gets enough

calcium at lower water cement ratios so that surplus calcium is

available in solution to aid the cement hydration and hardening

reactions contributing to better strength development. From

(Figure 4) the fabric changes happening over reduction in W/C