410

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

From Figures 8 and 11 it is also clear that to compact material

in field, a heavy equipment is more effective than to apply many

passes of a light one.

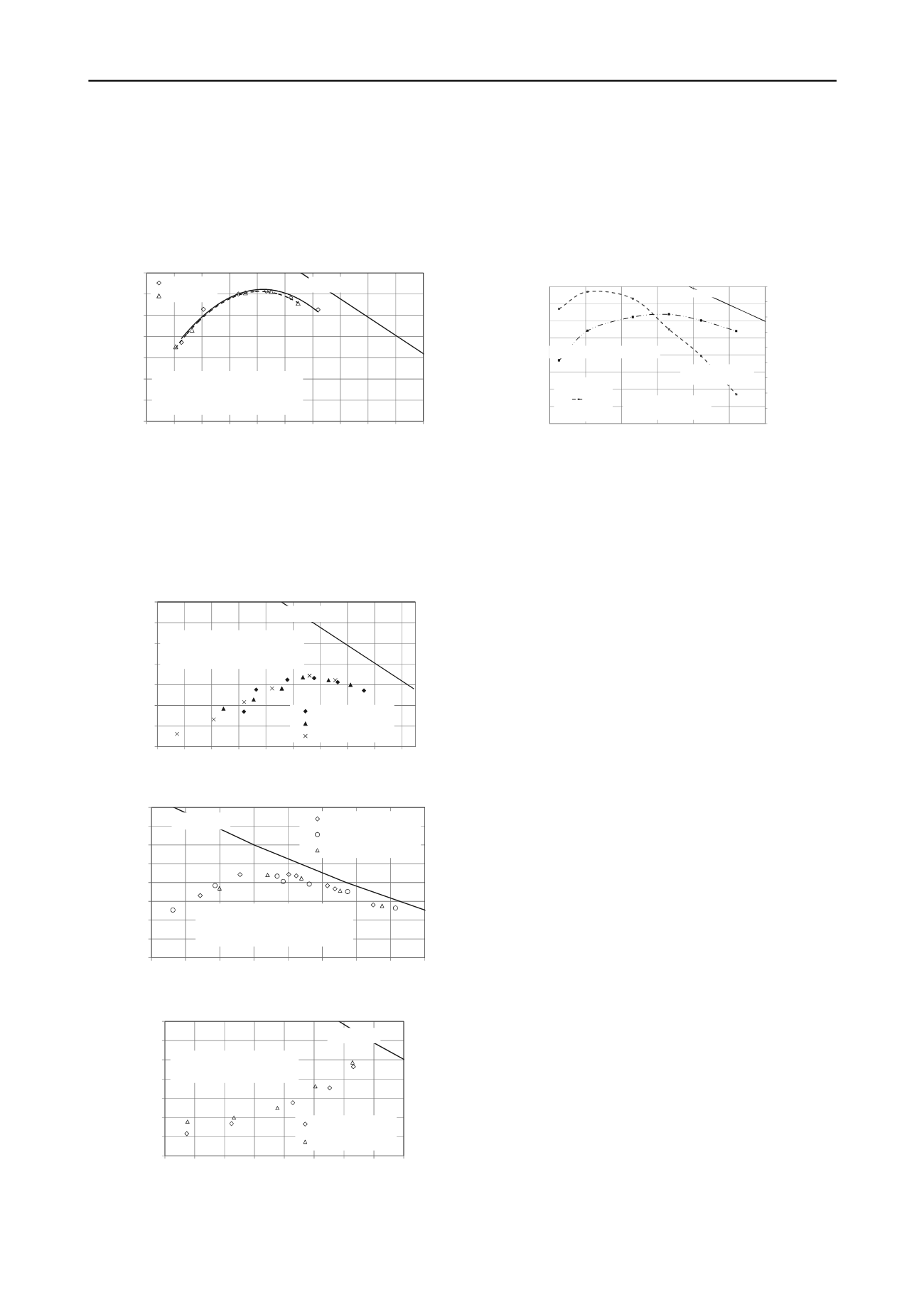

5.2.2 Gyration angle

The data obtained in this study indicates that the compaction

curve is independent of the gyration angles, at least for the two

gyration angles studied (Figure 12).

12.0

12.5

13.0

13.5

14.0

14.5

15.0

15.5

14 16 18 20 22 24 26 28 30 32 34

Dry unit weight (kN/m

3

)

Water content (%)

1.25 degrees

1 degree

Vertical pressure = 600 kPa

Rate: 10 gyrations/minute

Dry unit weights at 500 gyrations

S

r

= 100 %

Figure 12.Effect of gyration angle (CH soil).

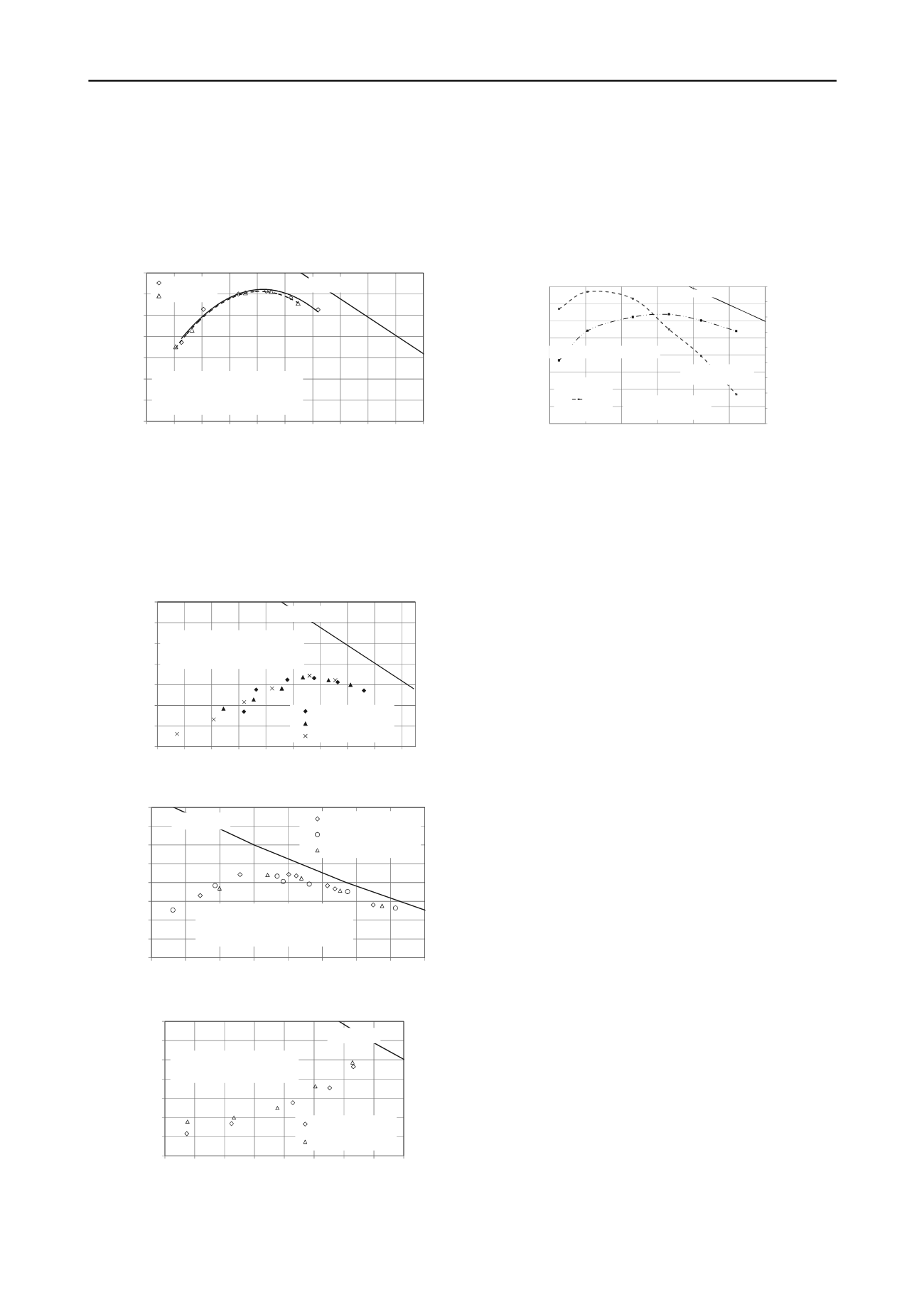

5.2.3 Gyration angle

The data obtained in this study indicates that the compaction

curve is independent of the gyration rate, at least for the three

gyration rates studied (Figures 13, 14 and 15). Thus, for

practical purposes it is convenient to carry out the tests at the

highest velocity tested in this study.

12.0

12.5

13.0

13.5

14.0

14.5

15.0

15.5

16 18 20 22 24 26 28 30 32 34

Dry unit weight (kN/m

3

)

Water content (%)

10 gyrations/minute

20 gyrations/minute

30 gyrations/minute

Vertical pressure = 200 kPa

Gyration angle: 1.25 degrees

Dry unit weights at 500 gyrations

S

r

= 100 %

Figure 13.Effect of gyration rate (CH soil).

11.0

11.5

12.0

12.5

13.0

13.5

14.0

14.5

15.0

25 27 29 31 33 35 37 39 41

Dry unit weight (kN/m

3

)

Water content (%)

10 gyrations/minute

20 gyrations/minute

30 gyrations/minute

S

r

= 100 %

Vertical pressure: 200 kPa

Gyration angle: 1.25 degrees

Dry unit weights at 500 gyrations

Figure 14.Effect of gyration rate (ML soil).

12.0

12.5

13.0

13.5

14.0

14.5

15.0

15.5

12 14 16 18 20 22 24 26 28

Dry unit weight (kN/m

3

)

Water content (%)

10 gyrations/minute

30 gyrations/minute

S

r

= 100 %

Vertical pressure: 200 kPa

Gyration angle: 1.25 degrees

Figure 15.Effect of gyration rate (SM soil).

5.3 Shear stresses from gyratory compaction

The data registered during the compaction in the gyratory

compactor not only includes the height of the specimen, the

vertical pressure and the gyration angle, it also contains the

shear stress developed during the whole process of compaction.

Figure 16 shows an example of the magnitude of the shear

stresses that can be developed during the process of compaction

of a claywith 600 kPa of vertical pressure.

12.2

12.6

13.0

13.4

13.8

14.2

14.6

15.0

15.4

15.8

110

130

150

170

190

210

230

250

270

16

18

20

22

24

26

28

Shearstress (kPa)

Watercontent (%)

Vertical pressure= 600 kPa

Rate = 10 gyrations/minute

Gyrationangle =1.25 degrees

500

Dry unit weight (kN/m

3

)

S

r

=100 %

Shear stresscurve

at 500 gyrations

Compactioncurve at 500 gyrations

Figure 16.Shear stress curve for CH soil (600 kPa of vertical pressure).

From Figure 16 it can be observed that the shear stress tends

to increase when the compacted soil is on the dry side of the

compaction curve, however, close to the optimum, the shear

stresses are reduced. It was expected because as the water

content increases the contacts between grains are reduced and as

a consequence the shear stresses are reduced.

6 CONCLUSIONS

The study of the behavior of compacted soils is of paramount

importance becuase this kind of material is involved in the

construction of almost all civil engineering structures. Its

quality control has been determined by the evaluation of two

parameters, that is to say, the field and laboratory density. To

evaluate the second one, the standard or modified Proctor tests

have been in use long time ago, however, these test are far from

developing the same soil structure provided for example for a

sheepsfoot roller which are utilized to compact fine-grained

soils. For this reason, the gyratory compactor has been put

forward as a new lab equipment to determine the standard and

modified compaction curves. This paper presented a series of

compaction curves developed in this equipment. It was

observed that there are a series of combinations of variables that

can be controlled in the gyratory compactor to obtain the

standard compaction curve. On the other hand, the compaction

curves seems to be independent of variables as the gyration

angle and the gyration rate, at least for the two gyration angles

studied and the three velocities. In addition, it is clear that to

increase the dry density of a soil, it is more effective to utilize

heavy equipment that many passes of a light one.

7 REFERENCES

Milberger, L., Dunlap, W. (1966). A gyratory compactor for molding

large diameter triaxial specimens of granular materials.Research

report number 99-2.Texas Highway department in cooperation with

the U.S. Department of Commerce.

Mokwa, R., Cuelho, E., y Browne, M. (2008). Laboratory Testing of

Soil Using Superpave Gyratory Compactor.Transportation

Research Board, 2008.

Ping, W.V., Xing, G., Leonard, M., y Yang, Z. (2003).Evaluation of

Laboratory Compaction Techniques for simulating field soil

compaction (Phase II). Report No. FL/DOT/RMC/BB-890(F).

mpactor_33.

Norma ASTM D 698-07e1, Standard Test Methods for Laboratory

Compaction Characteristics of Soil Using Standard Effort (12 400

ft-lbf/ft

3

(600 kN-m/m

3

)).