408

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

(a)

(b)

(c)

Figure 1. Places from where the soils were sampled. (a) Silt (ML); (b)

Sand (SM); and (c) Clay, CH.

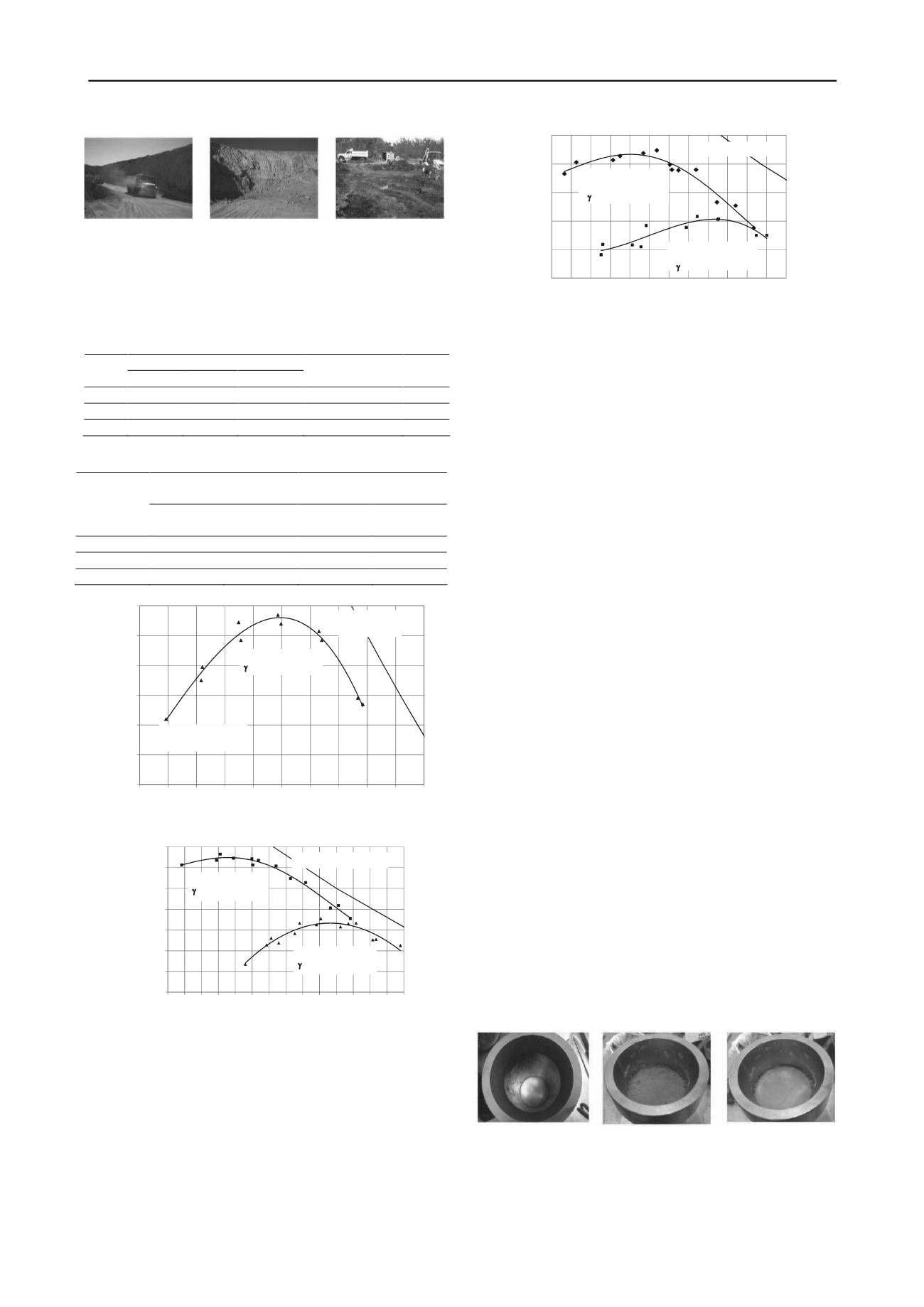

The index properties of the soils are listed in Table 1 and the

compaction characteristics obtained from Proctor and modified

tests are summarized in Table 2 (Figure 2 a 4).

Table 1.Index properties of the test soils.

Atterberg limits

Soil

Type LL (%) PL (%) PI (%)

% passing 200

sieve (%)

G

s

CH 66

25

41

85.7

2.61

ML 44

33

11

87.0

2.56

SM NP

NP

NP

37.0

2.52

Table 2.Compaction characteristics.

Standard effort (ASTM

D698)

Modified effort (ASTM D

1557)

Soil type

w

opt

(%)

dmax

(kN/m

3

)

w

opt

(%)

dmax

(kN/m

3

)

CH

30.0

13.32

---

---

ML

30.5

13.33

24.5

14.59

SM

23.54

14.04

19.0

15.17

12.2

12.4

12.6

12.8

13.0

13.2

13.4

20 22 24 26 28 30 32 34 36 38 40

Dry unit weight (kN/m

3

)

Water content (%)

Proctor standard

CH Soil

Sr = 100%

G

s

= 2.61

w

opt

=

30 %

dmax

=

13.32 kN/m

3

Figure 2.Compaction curve of the CH soil.

12.0

12.4

12.8

13.2

13.6

14.0

14.4

14.8

21 22 23 24 25 26 27 28 29 30 31 32 33 34 35

Dry unit weight (kN/m

3

)

Water content (%)

S

r

= 100 %; G

s

= 2.56

w

opt

= 24.5 %

dmax

= 14.59 kN/m

3

w

opt

= 30.5 %

dmax

= 13.33 kN/m

3

Figure 3. Compaction curves of the ML soil.

13.0

13.5

14.0

14.5

15.0

15.5

15 16 17 18 19 20 21 22 23 24 25 26 27

Water content (%)

Dry unit weight (kN/m

3

)

Modified

w

opt

= 19 %

dmax

= 15.17 kN/m

3

Proctor standard

w

opt

= 23.54 %

dmax

= 14.04 kN/m

3

S

r

= 100 %; G

s

= 2.52

Figure 4. Compaction curves of the SM soil.

4 TEST PROCEDURES.

4.1 Compaction curves. Proctor standard and modified

(ASTM D698 and ASTM D 1557)

To obtain the standard and modified compaction curves, the

ASTM procedures were followed (ASTM D698 and ASTM

D1557). From these procecdures, the method A was utilized in

both cases since all material tested passed sieve number 4.

4.2 Compaction curves. Gyratory compactor

As was mentioned in previous paragraphs, in this equipment the

operator can control variables such as: vertical pressure, angle

of gyration, height of specimen, density, etc. In this study, the

controlled variables were as follows:

Vertical pressure: 200, 300, 400, 500, and 600 kPa.

Angle of gyration: 1 and 1.25 degrees

Number of gyrations: 500

Rate of gyrations: 10, 20 and 30 gyrations/min

Soil type: 3

Mass of compacted soil: 2300 g

Once the soils were gathered, the material larger than No. 4

sieve was discarded. The material passing was allowed to dry at

environmental conditions and subsequently itwas mixed

throughly and then stored in sacks.

For all three soils, the procedure followed to evaluate the

compaction curves was as follows:

1. 180 soil samples of 2300 g of dry soil (of each soil type)

were weighted so that to cover all the combinations of

the variables to be controlled (5 vertical pressures x 2

angles of gyration x 3 rates of gyration x 1 sample at

each point x 6 points on the compaction curve).

2. Different amounts of water were added to each sample

so that to cover the range in which the modified and

standard tests were found (to develop each curve, six

points were considered).

3. The soil samples were stored during 24 hours.

4. An amount of 2300 g of wet soil was placed inside the

compaction mold (Figure 5b and 5c), but previously

some plastic strips were placed on the interior wall of

the mold so that the soil did not stick and the sample

could be extracted (Figura 5a). In addition, another

plastic circle was placed on top of the soil so that it did

not stick against the top compaction platen.

(a)

(b)

(c)

Figure 5.(a) Strips inside the interior wall of the mold; (b) 2300g of wet

soil were placed in the mold, and, (c) A plasticcirclewas placed on top

of the mold for the soil not to stick to the compaction platen.