409

Technical Committee 101 - Session II /

Comité technique 101 - Session II

5. The mold was placed inside the machine (SERVOPAC).

It was programmed to compact the soil at a required

angle of gyration, vertical pressure and 500

gyrations.This step was repeated for the 180 samples of

each soil type.

6. After the sample was compacted at 500 gyrations, it was

extracted. The dimensions and weight were taken and

registered.

(a)

(b)

Figure 6.(a) Ejection of the compacted sample; (b) the dimensions of the

sample were taken.

7. In the final step the sample was taken apart to obtain

samples to determine el water content.

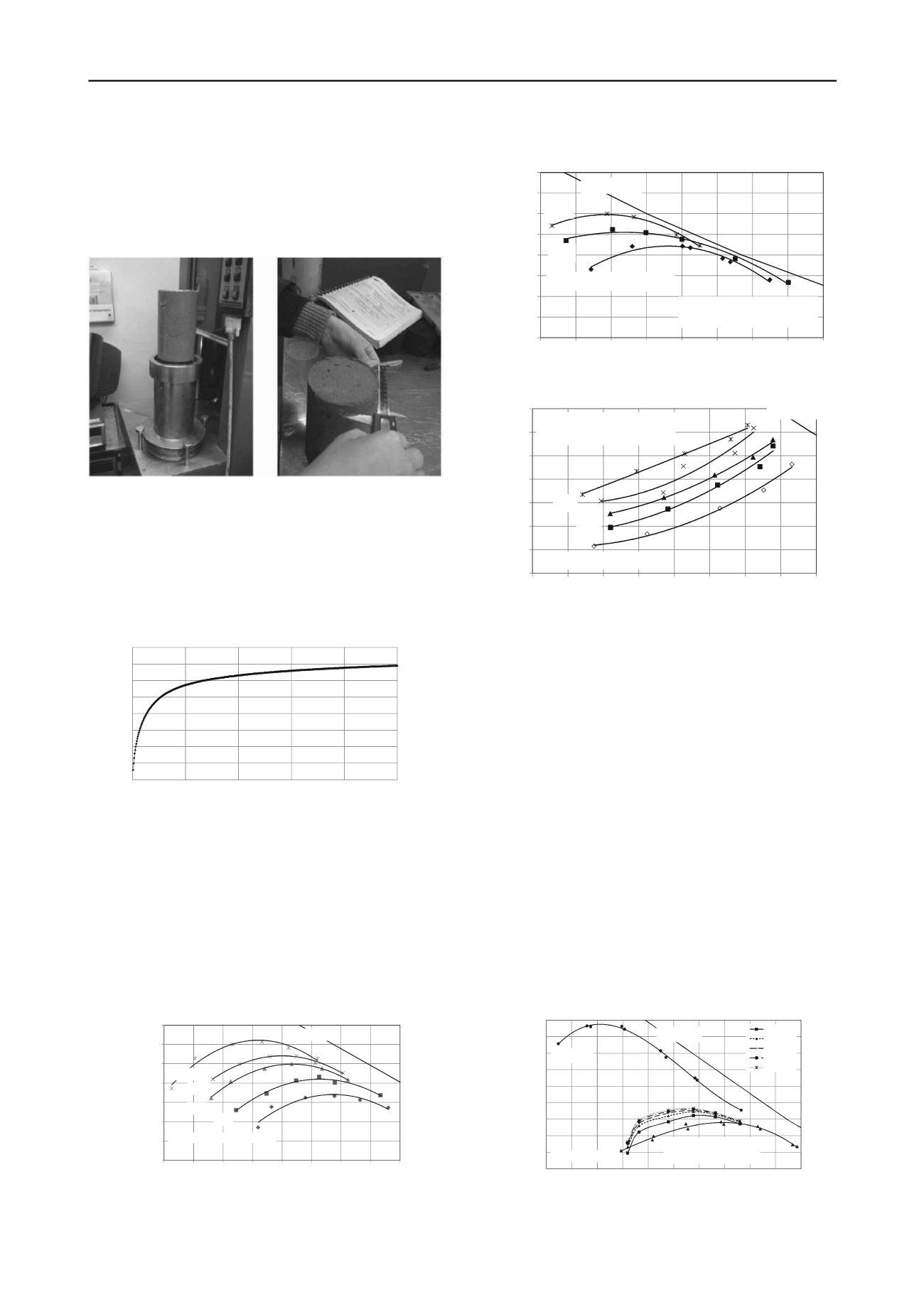

8. With data of water conent, height of the specimen and

dimensions, the dry unit weight was calculated at every

gyration. A typical plot obtained for every single

sample is ilustrated in Figure 7.

11.6

11.8

12.0

12.2

12.4

12.6

12.8

13.0

13.2

0

100

200

300

400

500

Dry unit weight (kN/m

3

)

Gyration number

Figure 7.Typical plot of dry unit weight versus gyration number

From Figure 7 data at 100, 200, 300, 400, and 500 gyrations

were taken to plot the compaction curves.

5 DISCUSION OF RESULTS

5.1 Compaction curves from gyratory compactor

Figure 8, 9 and 10 illustrates the compaction curves obtained at

different vertical pressures, 1.25 angle of gyration, 10 gyrations

per minute and for each soil type. The dry unit weight plotted in

these figures was taken at gyration number 500.

12.0

12.5

13.0

13.5

14.0

14.5

15.0

15.5

16

18

20

22

24

26

28

30

32

Dry unit weight (kN/m

3

)

Water content (%)

Vertical pressure = 200 kPa

300

400

500

600

S

r

= 100 %

Figure 8. Compaction curves for CH soil.

11.0

11.5

12.0

12.5

13.0

13.5

14.0

14.5

15.0

25 27 29 31 33 35 37 39 41

Dry unit weight (kN/m

3

)

Water content (%)

Sr = 100 %

Vertical pressure: 200 kPa

300

600

Rate: 10 gyrations/minute

Gyration angle: 1.25 degrees

Figure 9. Compaction curves for ML soil.

12.0

12.5

13.0

13.5

14.0

14.5

15.0

15.5

10 12 14 16 18 20 22 24 26

Dry unit weight (kN/m

3

)

Water content (%)

S

r

= 100 %

Vertical pressure: 200 kPa

300

600

Rate: 10 gyrations/minute

Gyration angle: 1.25 degrees

Figure 10. Compaction curves for SM soil.

As can be noted from Figures 8, 9 and 10, the dry unit weight

increases and the optimum water content is reduced as the

vertical pressure increases, however, this trend is clear for the

CH and ML soil. On the other hand, for the SM soil, the dry

unit weight increases, but for water contents larger than the

optimum of the Proctor standard test, the material cannot be

compacted because water starts to flow out of the mold. For this

reason, the compaction curves do not show the maximum dry

unit weight that can be observed in the standard compaction

curve obtained by impacts.

5.2 Effect of different variables on the compaction curve

5.2.1 Gyration number

In Figures 8 to 10 the value of dry unit weight that was plotted

was calculated at gyration number 500, however, for each

compacted sample, it was obtained a curve of gyration number

versus dry unit weight. Thus, to detect the effect of the number

of gyrations, some of the compaction curves were plotted on the

compaction space together with the standard and modified

curves (Figure 11). As seen from this figure and also from

Figure 7, the mayor change in the dry unit weight is noted in the

first 100 or 200 cycles. For further gyrations, there is only a

slow change in dry unit weight. Thus, it can be concluded that

the soil can be compacted with 100 or 200 gyrations.

12.2

12.6

13.0

13.4

13.8

14.2

14.6

15.0

15.4

15.8

16 18 20 22 24 26 28 30 32 34 36

Dry unit weight (kN/m

3

)

Watercontent (%)

Vertical pressure = 200 kPa

Rate = 10 gyrations/minute

Gyration angle = 1.25 degrees

100 giros

200

300

400

500

Modified

Proctor standard

Sr = 100 %

Figure 11. Effect of number of gyrations on the compaction curve (CH

soil).