135

Honour Lectures /

Conférences honorifiques

9

o e

d g g

g

C C

J D K

L

(6)

where

D

g

is the diffusion coefficient for the chemical in the

GML. Conservative (high) estimates of

J

d

will occur when

C

e

is assumed to be zero.

Since geomembranes are not porous media, the nature

of

D

g

is not the same as that of

D

*

. For example, based on

an extensive summary of both

K

g

and

D

g

values from the

literature reported by Rowe (1998), the upper limit on the

vast majority of the

D

g

values is on the order of 1 x 10

-1l

m

2

/s, with numerous values ranging from one to several

orders of magnitude lower than this value. Thus, values of

D

g

generally are several orders of magnitude lower than

values of

D

*

. However, despite such low magnitude

D

g

values, Park et al. (1996b) illustrate that molecular

diffusion of organic chemicals through intact GMLs can be

substantially greater than leakage through geomembrane

defects. A major reason for this difference is that that

cross-sectional area for diffusive mass flux through a GML

is the entire surface of the GML, whereas mass flux due to

leakage through a GML is associated with only a small

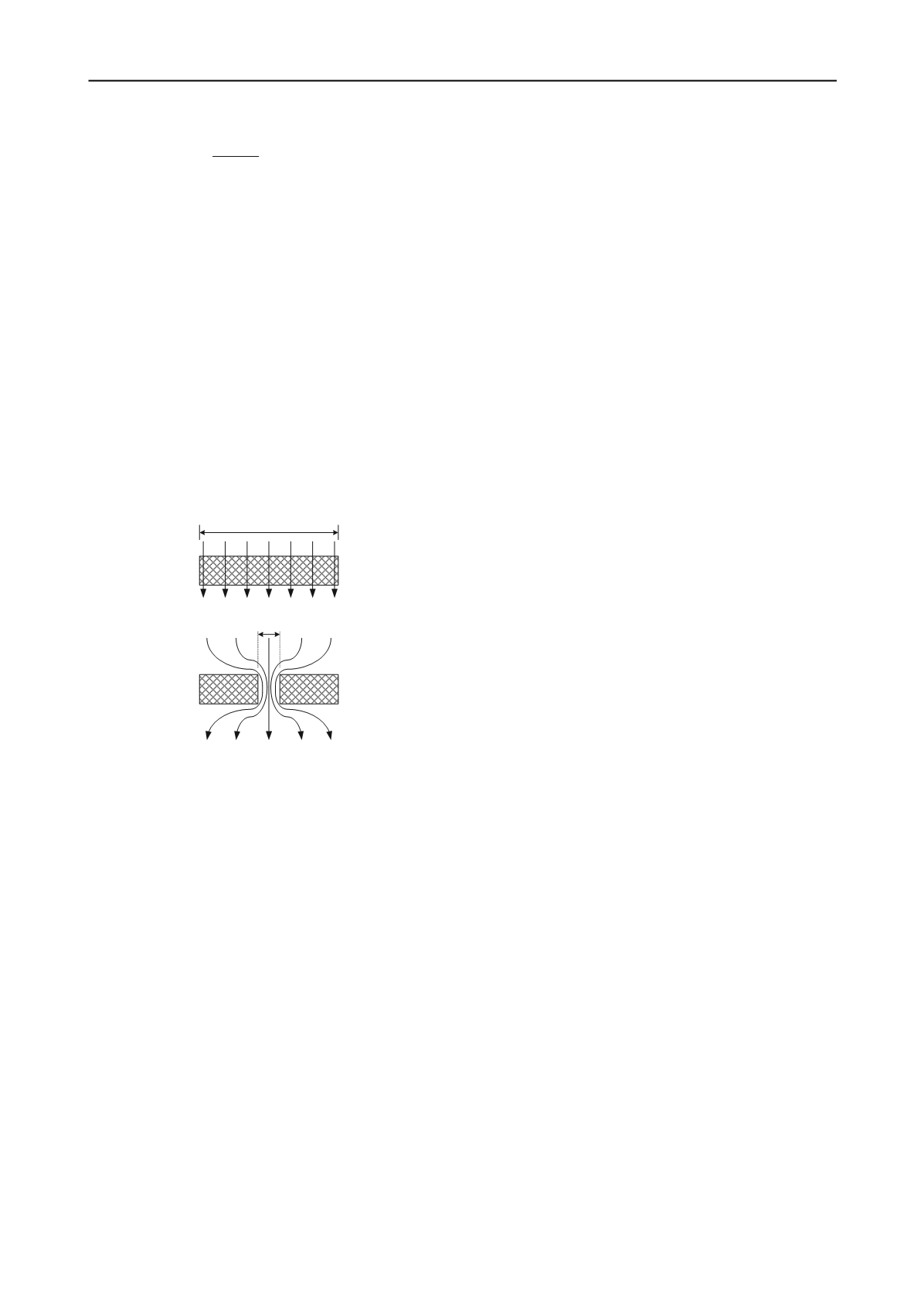

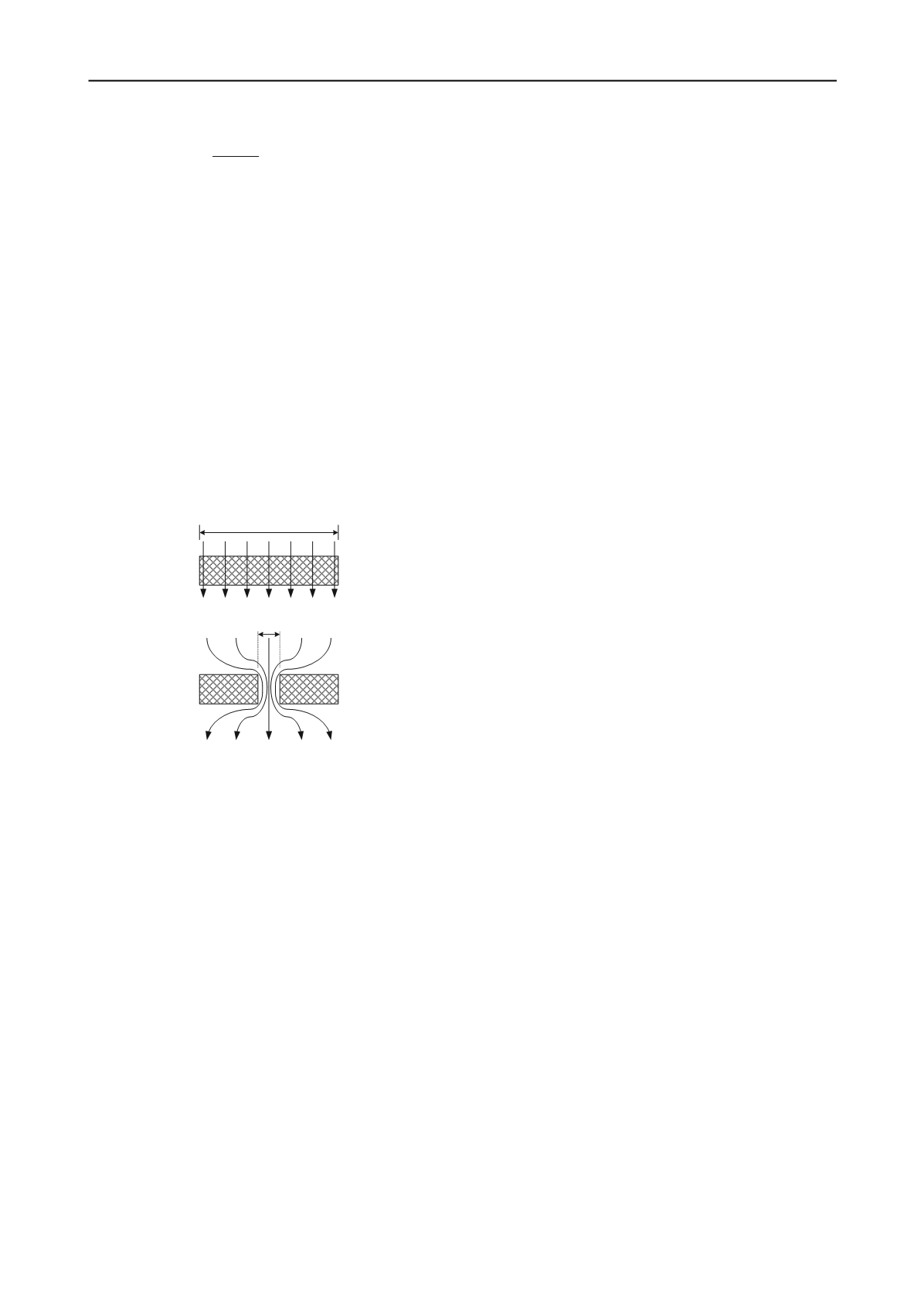

percentage of the surface area (see Fig. 8).

Leakage through Defect Area,

A

d

Area,

A

Diffusion

Figure 8. Cross-sectional areas for diffusion versus leakage

through a GML.

Because diffusion of VOCs through single polymer

GMLs has been an issue, recent research has focused on

evaluating alternative GMLs for the ability to minimize

VOC diffusion. For example, Sangam and Rowe (2005)

evaluated the effect of fluorinating the surface of an HDPE

on the diffusion of VOCs through the GML. In essence,

the surface fluorination reduces the affinity of the GML to

VOCs. Sangam and Rowe (2005) reported that the

diffusion coefficient for the surface fluorinated HDPE was

on the order of 1.5 to 4.5 times lower than that for the

untreated HDPE, depending on the specific hydrocarbon

evaluated. Similarly, McWatters and Rowe (2010)

evaluated the ability of two coextruded GMLs to reduce

the diffusive flux of VOCs. Coextrusion involves

extruding two or more layers of dissimilar polymers into a

single film. McWatters and Rowe (2010) reported

improved resistance to BTEX diffusion for the two

coextruded GMLs, a polyamide (nylon) GML and an

ethylene vinyl-alcohol (EVOH) GML, relative to that for

either an LLDPE or a PVC GML. The results of these and

other studies indicate that alternatives to the single

polymer GMLs may offer improved performance in terms

of VOC diffusion.

4.2.4

Diffusion through Geosynthetic Clay Liners

Geosynthetic clay liners (GCLs) are relatively new barrier

materials, having first been used in a landfill in 1986

(Bonaparte et al. 2002). Traditional or conventional GCLs

are thin (~ 5 to 10 mm), prefabricated (factory

manufactured) hydraulic barriers (liners) that consist

primarily of a processed clay, typically sodium bentonite,

or other low permeability material that is either encased or

"sandwiched" between two geotextiles or attached to a

single polymer membrane (i.e., geomembrane) and held

together by needle-punching, stitching, and/or gluing with

an adhesive. The hydraulic resistance of these conventional

GCLs that do not include a geomembrane or polymer film

is attributed to the bentonite component of the GCL, which

swells in the presence of water to form a tight sealing

layer. Although GCLs can be subjected to significant

incompatibility upon permeation with chemical solutions

or liquids, resulting in potentially significant increases in

hydraulic conductivity, the values of

k

h

for GCLs

permeated with dilute chemical solutions or water tend to

be less than about 1 x 10

-10

m/s (e.g., Shackelford et al.

2000). Such low

k

h

values and the relative thinness of

GCLs imply that diffusion would be a significant, if not

dominant, transport process through GCLs. Accordingly,

several studies have evaluated the diffusion of chemicals

through GCLs (Lake and Rowe 2000, 2005, Rowe et al.

2000, Malusis and Shackelford 2002a, Lange et al. 2009,

Paumier et al. 2011, Malusis et al. 2013).

For example, consider the results of the study shown in

Fig. 9 for diffusion of KCl through a GCL. In this study,

diffusion of KCl was hypothesized to be affected by the

ability of the bentonite in the GCL to exhibit

semipermeable membrane behavior, whereby solutes are

excluded from the smaller pores in the clays, thereby

restricting the diffusion of the KCl (Malusis and

Shackelford 2002b). Such solute restriction also results in

chemico-osmosis, or the movement of liquid from lower

solute concentration to higher solute concentration, or

opposite to the direction of diffusion. Accordingly, the

GCL was tested in an apparatus that was able to measure

simultaneously both the membrane efficiency of the GCL

and the

D

*

of the KCl.

The membrane efficiency refers to the relative degree

or extent of solute restriction (also referred to as "ion

exclusion"), and is quantified in terms of a membrane

efficiency coefficient,

(Shackelford et al. 2003).

Although negative values of

have been reported in some

cases due to atypical circumstances resulting from

processes such as "diffusion-osmosis" (Olsen et al. 1990),

values typically range from zero for clays exhibiting no

membrane behavior and, therefore, no solute restriction, to

unity (100 %) for "perfect" or "ideal" membranes that

restrict the passage of all solutes. Because soils generally

exhibit a range of pore sizes, some of the pores in clays

may be restrictive whereas others are not. As a result, most

natural soils that exhibit membrane behavior do so as

"imperfect" or "non-ideal" membranes, such that 0 <

< 1

(Shackelford et al. 2003). In particular, bentonite has been

shown to possess the potential for significant membrane

behavior, such that the possible effect of membrane

behavior on solute transport through any bentonite-based

barrier should be considered (Shackelford 2011, 2012,

2013).

In terms of the results in Fig. 9, Fig. 9a shows the

correlation between the measured value of

for the GCL

and the source concentration of KCl,

C

o

, used in the test.

Due to physico-chemical interactions between the salts in

the pore water of the bentonite and the bentonite particles,