1303

Technical Committee 202 /

Comité technique 202

The tunnel structure 2 above the belt conveyor is founded by

the vibration-free CMC method. For the construction of the

15 m tall embankment 70 m wide at its base, the stone columns

technology were used.

Figure 6 gives an overview of the different improvement

techniques carried out in the area of the belt conveyors

structure 2. The longitudinal section elevations showed a height

difference of respectively 1.75 m. The shallow stone columns

reach 10 m to 15 m deep.

Figure 6. 15m high difference including ripping holes for the two

devices RSV, CMC directly on BW2 and pressumeter PMT in front.

4 RESULTS OF THE SOIL IMPROVEMENT

Hereafter, examples of results for the stone columns treatment

area are shown. Test areas and boring before and after treatment

were performed near the highest embankment section to be able

to derive the soil parameters of the calculation model.

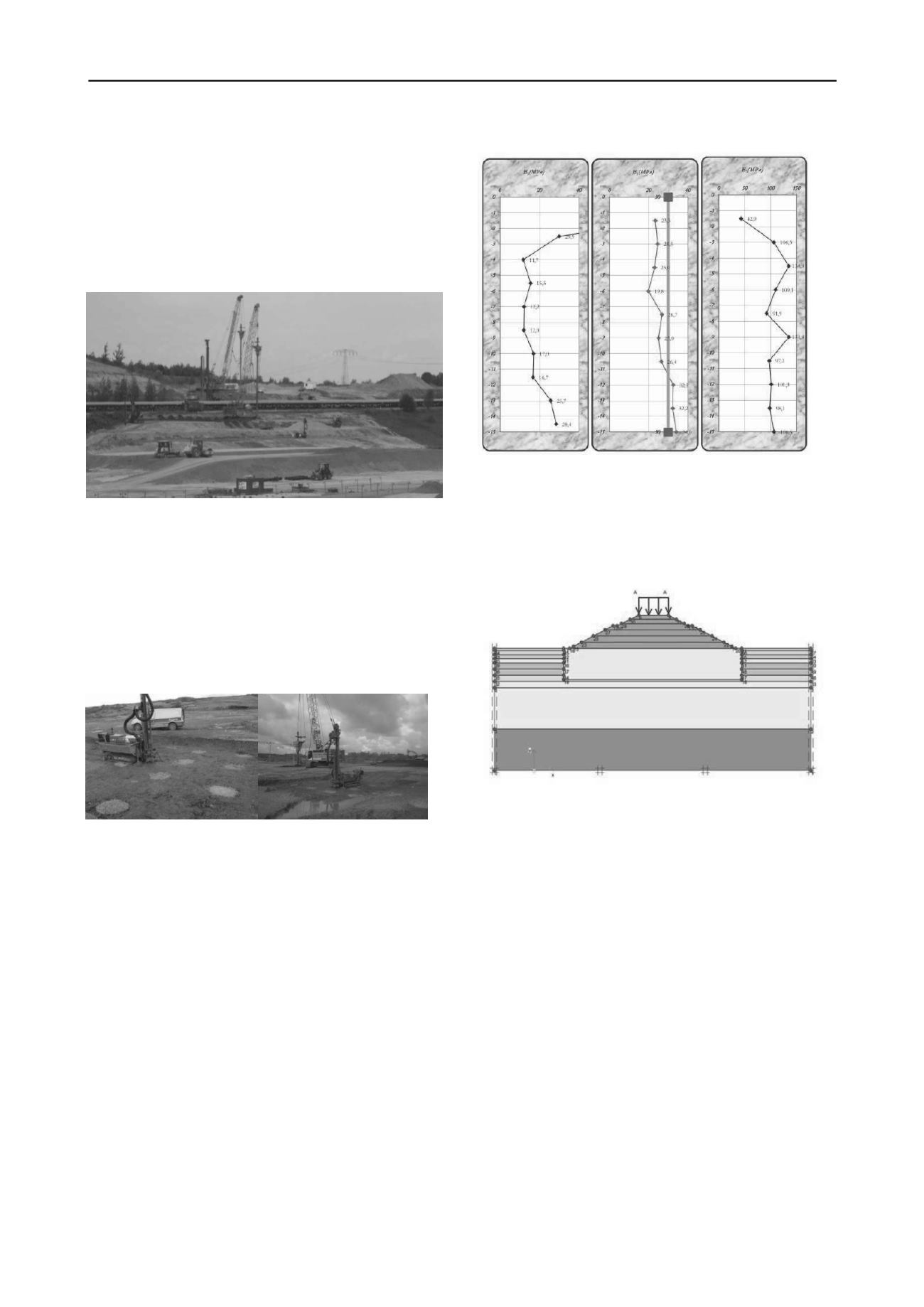

The Menard pressuremeter tests were performed within the

stone columns and in the center of the grid of installation.

Figure 7. Execution of the Ménard pressuremeter between and centrally

in the columns

Due to the compaction at optimum proctor water content

corresponding to figure 8 most often an improvement between

the columns with the factor of 2 was measured. With the mean

stiffness modulus of E

c

= 100 MN/m

2

in the columns with at

least 70 cm diameter, this results in a 3 times higher design

relevant modulus of E

s

=30 MN/m

2

for the improved ground.

The Stiffness modulus was doubled after treatment in the

center of the grid of installation, in between columns. This fairly

remarkable result was made possible by the water content close

to the optimum Proctor of the deposits of the mining ground,

and also by the powerful V23 vibrator. A transfer of these high

values to other constructions projects without these optimal

conditions is not possible and it is highly recommended to use a

project-specific calibration with test fields and the Ménard

pressuremeter for other projects.

The results of the cone penetration tests also showed an

improvement factor of 2. It should be noted that the initial

values may have been too low. The improvement as shown by

CPT`s is similar to the Ménard pressuremeter. The stiffness

modulus in cohesive soils can only be measured by

pressuremeter and oedometer tests on undisturbed soil samples.

Preliminary investigation between columns

centrally in columns

Figure 8. Results from in-between and at the center of the columns

5 NUMERICAL ESTIMATION OF SETTLEMENT

Based on the design soil parameters, the settlement calculation

was created in the course of a Diploma thesis (Vogel 2011) with

the PLAXIS software.

Figure 9. CAD model and PLAXIS model

The layers of the fill deposit from ground level up are

divided per figure 9 into different layers. The first 20 meters

from the edge of the model to the toe of the embankment are

modelled using the thin layered structure of the graded soil

charactistics of the dump.

The improvement depth by stone columns below the

embankment was 15 m. This improved ground beneath the dam

is modelled using a composite layer with a composite average

modulus E

s

= 30 MN/m

2

.

The last two layers of fill are assumed to be each 20 m thick

at the lower part of the model domain.

As part of the thesis (Vogel 2011), different behaviour laws

for the modelling of the stress-strain relation of the fill material

were compared and each corresponding calculations resulted in

very variable estimation of the settlements. Between the linear-

elastic, perfectly plastic Mohr Coulomb model with one meter

expected settlements to the more realistic elastoplastic

Hardening Soil model, a difference of half a meter in the

estimated long term settlement were calculated using PLAXIS

software.

In this paper, we present the results of the Hardening Soil

model, where the stiffness modulus for the settlement

calculation for the next load level are sequentially recalculated

and increased after each load level according to oedometer and

pressuremeter test results.

Each of the following six stages corresponds to an

embankment height increase of nearly 3 m with corresponding