1308

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

0

20

40

60

80

100

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

Amount of sand (%)

Before Tamping

After Tamping

0

20

40

60

80

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

2.2

100

c

Amount of sand (%)

Before Tamping

After Tamping

Figure 14. Relationships of

u

2

and

0.036

0.040

0.044

0.048

0.052

0.056

0.2

0.3

0.4

0.5

0.6

0.7

0.8

u

2

(mm)

Before Tamping

After Tamping

0.036

0.040

0.044

0.048

0.052

0.056

0.002

0.004

0.006

0.008

0.010

0.012

u

2

(mm)

Before Tamping

After Tamping

Figure 17. Relationships of

and % sand

0

20

40

60

80

0.000

0.002

0.004

0.006

0.008

0.010

0.012

100

Amount of sand (%)

Before Tamping

After Tamping

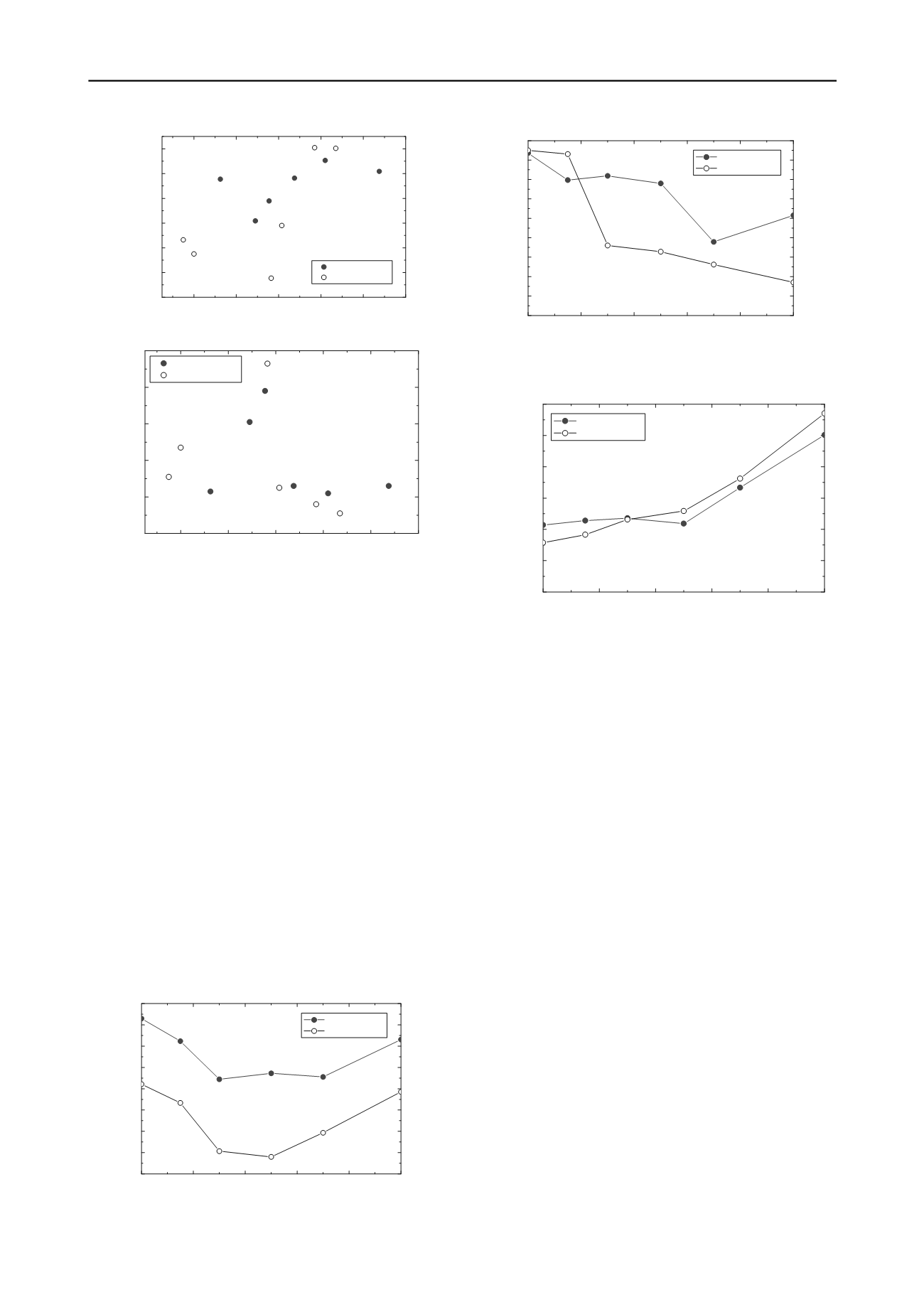

Figure 15. Relationships of

u

2

and

3.3 Effects of tie tamping application on settlement

characteristics

Figure 18. Relationships of

and % sand

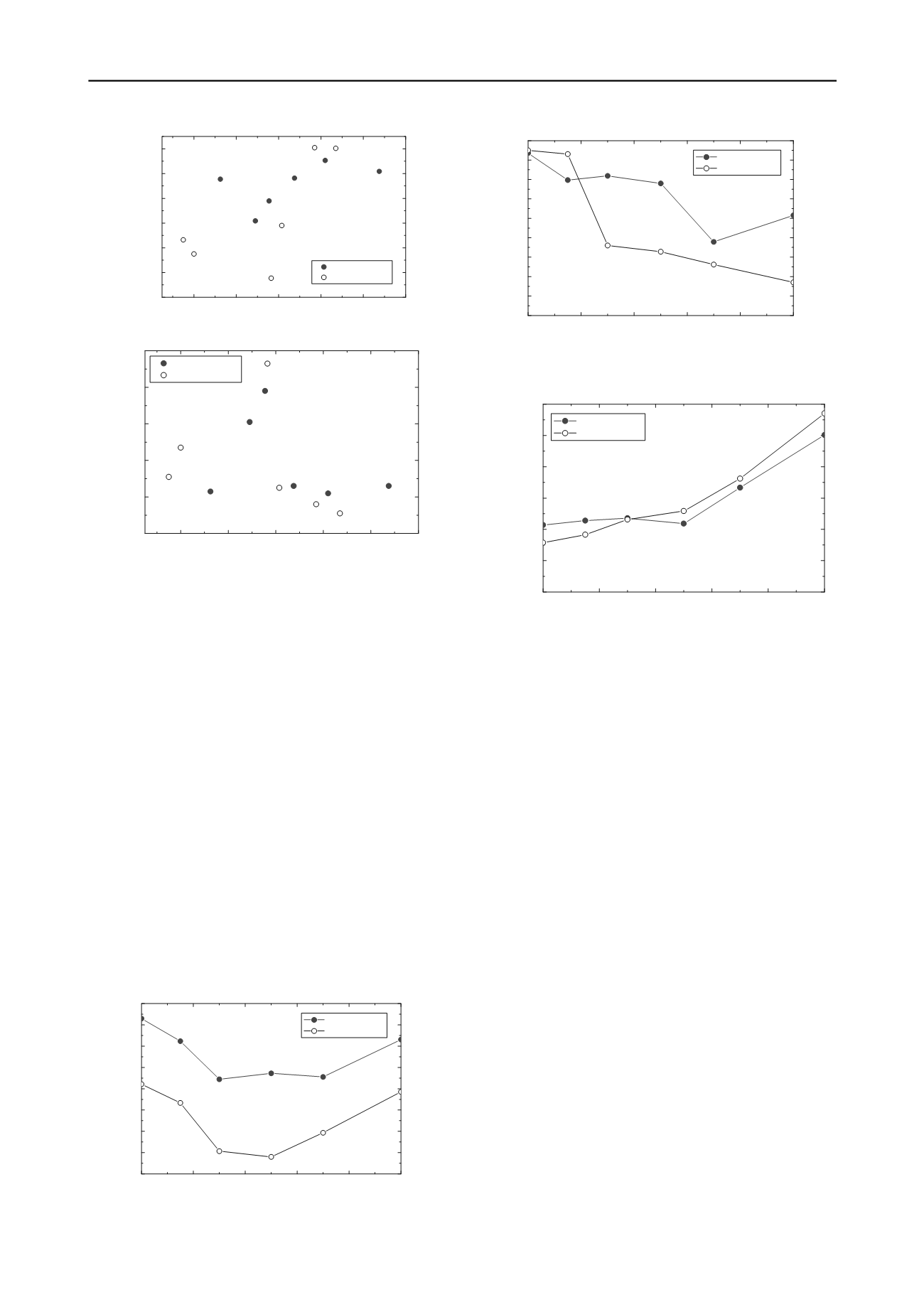

Figures 16-18 show how

c

,

and

change with %sand. Figure

16 shows that

c

, parameter indicating initial settlement amount,

reduces until 30-50% sand and then increases, almost same as

how

e

max

and

e

min

change with %sand (Figure 3). While

parameter indicating period of initial settlement process,

reduces with %sand,

, parameter indicating rate of residual

settlement, increase with %sand. The results of

can be

interpreted as initial settlement period increases with degree of

fouled ballast (i.e., increasing of %sand). The results of

can be

interpreted as rate of residual settlement increases with degree

of fouled ballast (i.e., increasing of %sand).

4 CONCLUSIONS

The effects of sand intrusion into ballast and tie tamping

application on settlement characteristics were investigated using

series of cyclic loading model tests. The following conclusions

were derived from this research:

(1) The characteristics of the initial settlement process are

altered considerably after tie tamping application; especially if

ballast is mixed by more than 30% fine materials.

As shown in Figure 16,

c

reduces with %sand up to 30-50% and

then increases. This tendency is same for both before and after

tie tamping application. However, change of

with %sand is

more after tie tamping application for the specimens with more

than 15% sand. That’s, initial settlement period increases

significantly with %sand after tie tamping application (Figure

17). The results also showed that rate of residual settlement is

higher after tie tamping application for the specimens with more

than 30% sand (Figure 18). That’s, tie tamping application

seems effective for fouled ballast mixed with up to 30% fines.

(2) Rate of residual settlement increases after tie tamping

application if ballast is mixed by more than 30% fine materials.

Therefore, tie tamping application seems effective for fouled

ballast with less than 30% fines.

5 ACKNOWLEDGEMENTS

Japanese Government is acknowledged for providing financial

assistance to the first author to study in Yokohama National

University, Japan through a Monbukagakusho scholarship.

6 REFERENCES

Indraratna B., Shahin M., Rujikiatkamjorn C. and Christie D. 2004.

Stabilisation of ballasted rail tracks and underlying soft formation

soils with geosynthetics grids and drains. GeoShanghai

International Conference, Shanghai, China, June 2-4, 2006.

Kumara G.H.A.J.J., Hayano K., Ogiwara K. and Takeuchi M. 2012.

Fundamental study on the simple evaluation methods for particle

size distribution and maximum/minimum void ratio of sand-

gravel mixtures, 2

nd

International Conference on Transportation

Geotechnics, Hokkaido, Japan, 572-577, September 10-12, 2012.

Sekine E., Ishikawa T. and Kouno A. 2005. Effect of ballast thickness

on cyclic plastic deformation of ballasted track, RTRI Report, 19

(2), 17-22 (in Japanese).

Figure 16. Relationships of

c

and % sand