1306

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

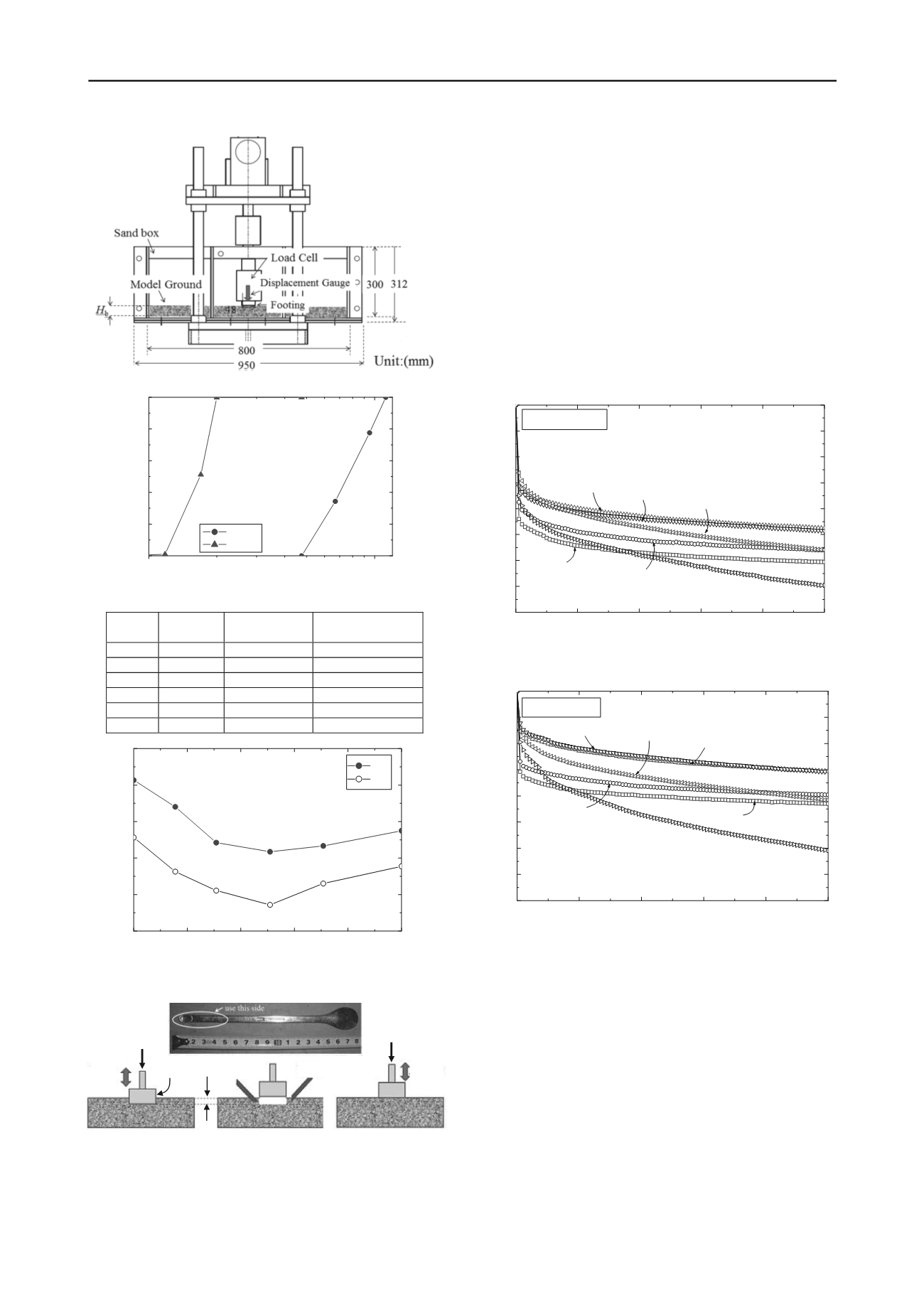

Figure 1. Model test apparatus for model test

0

20

40

60

80

100

3.2

2.8

2.4

2.0

1.6

1.2

0.8

0.4

0.0

Before Tamping

100% sand

70% sand

50% sand

30% sand

15% sand

Fresh ballast

Settlement,

S

(mm)

No of loading cycles,

N

100

3.2

2.8

2.4

2.0

1.6

1.2

0.8

0.4

0.0

0

20

40

60

80

After Tamping

70% sand

15% sand

50% sand

30% sand

100% sand

Fresh ballast

Settlement,

S

(mm)

No of loading cycles,

N

Figure 2. PSDs of gravel and M sand

Table 1. Model test conditions

Case

No

% sand

Dry density,

(kg/m

3

)

Relative density,

D

r

(%)

1

0

1519

80

2

15

1698

80

3

30

1829

80

4

50

1929

80

5

70

1788

80

6

100

1684

80

Figure 3. Max and min void ratios vs. % sand (Kumara et al., 2012)

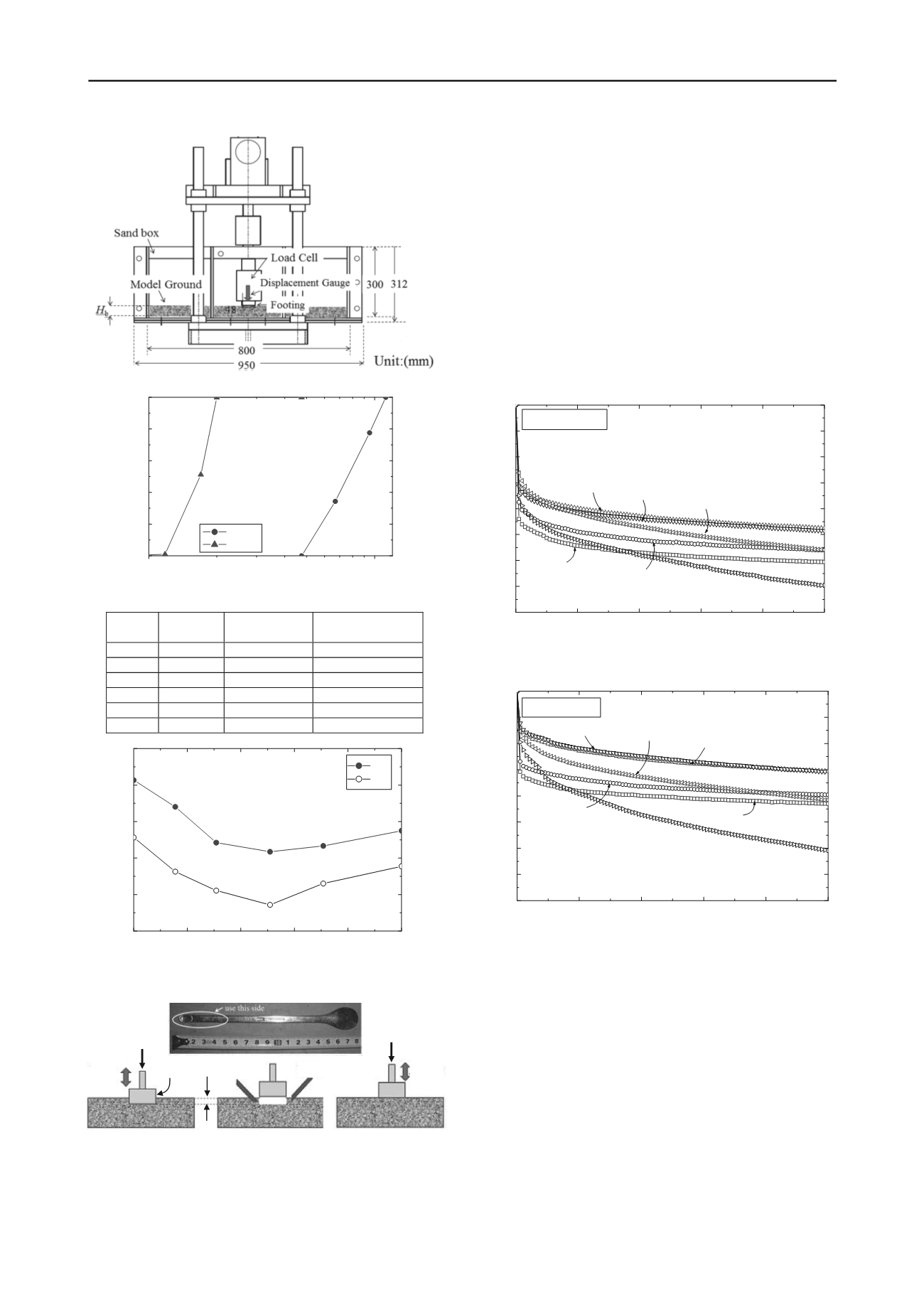

Figure 4. The tool and procedure used for simulating tie tamping

application

3 RESULTS

3.1 Effects of PSDs on settlement characteristics

Figures 5 and 6 show the results of settlement,

S

with no. of

loading cycles,

N

for fresh ballast (i.e., gravel) and fouled

ballast (i.e., 15, 30, 50, 70% and 100% sand) cases before and

after tie tamping application respectively. It clearly shows that

fouled ballast alters the settlement characteristics of fresh ballast

significantly, both before and after tie tamping application. As

shown in Figures 5 and 6, the smallest settlement was observed

in cases of 30 and 50% sand specimens. The smallest settlement

observed for 30 and 50% sand cases can be understood from the

results of void ratios,

e

max

and

e

min

with % sand as shown in

Figure 3 where it shows minimum values of void ratios were

observed for the mixtures with 30-50% sand.

1

2

3 4 5 6 7 8 9

0

20

40

60

80

100

10 12

Percent passing (%)

Grain size,

D

(mm)

Gravel

M sand

Figure 5. Relationships between no. of loading cycles and settlement

before tie tamping application

0

20

40

60

80

0.2

0.4

0.6

0.8

1.0

1.2

100

e

max

e

min

Max and min void ratio,

e

max

and

e

min

Amount of M sand (%)

Figure 6. Relationships between no. of loading cycles and settlement

after tie tamping application

Figure 7 shows the results of settlement at 100

th

loading cycle,

S

100

vs. %sand for all the tests and clearly indicates how PSDs

affect settlement both before and after tie tamping application.

The relationship is quite similar to

e

max

and

e

min

relationships

with % sand (Figure 3).

The relationships between no. of loading cycles,

N

and sleeper

settlement,

S

were obtained using Eq. 1 (Sekine et al., 2005),

100 loading cycles

Lift the sleeper by

Inserting

tie tamper and filling the gap

by moving it laterally

100 loading cycles

N=100

N=10

Tie tamper

Tie tamper

100 loading cycles

N=100

Ballast

Sleeper

p

=120kPa

p

=120kPa

N

e c S

N

1

(1)

where

c

and

represent the initial settlement process, and

represents the process of residual settlement. The relationships

for fresh ballast (i.e., gravel) and 30% sand cases are shown in

Figure 8.