1307

Technical Committee 202 /

Comité technique 202

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8

0

20

40

60

80

100

120

140

2.0

k

2

k

2

u

2

1

st

cycle

Applied pressure,

p

(kN/m

2

)

Settlement of sleeper,

S

(mm)

0

20

40

60

80

0.0

0.1

0.2

0.3

0.4

0.5

100

Before tamping

After tamping

M sand

u

2

(mm)

No of loading cycles,

N

30%

100

0

20

40

60

80

3.0

2.5

2.0

1.5

1.0

0.5

0.0

Settlement after 100 loading cycles,

S

100

(mm)

Amount of sand (%)

Before Tamping

After Tamping

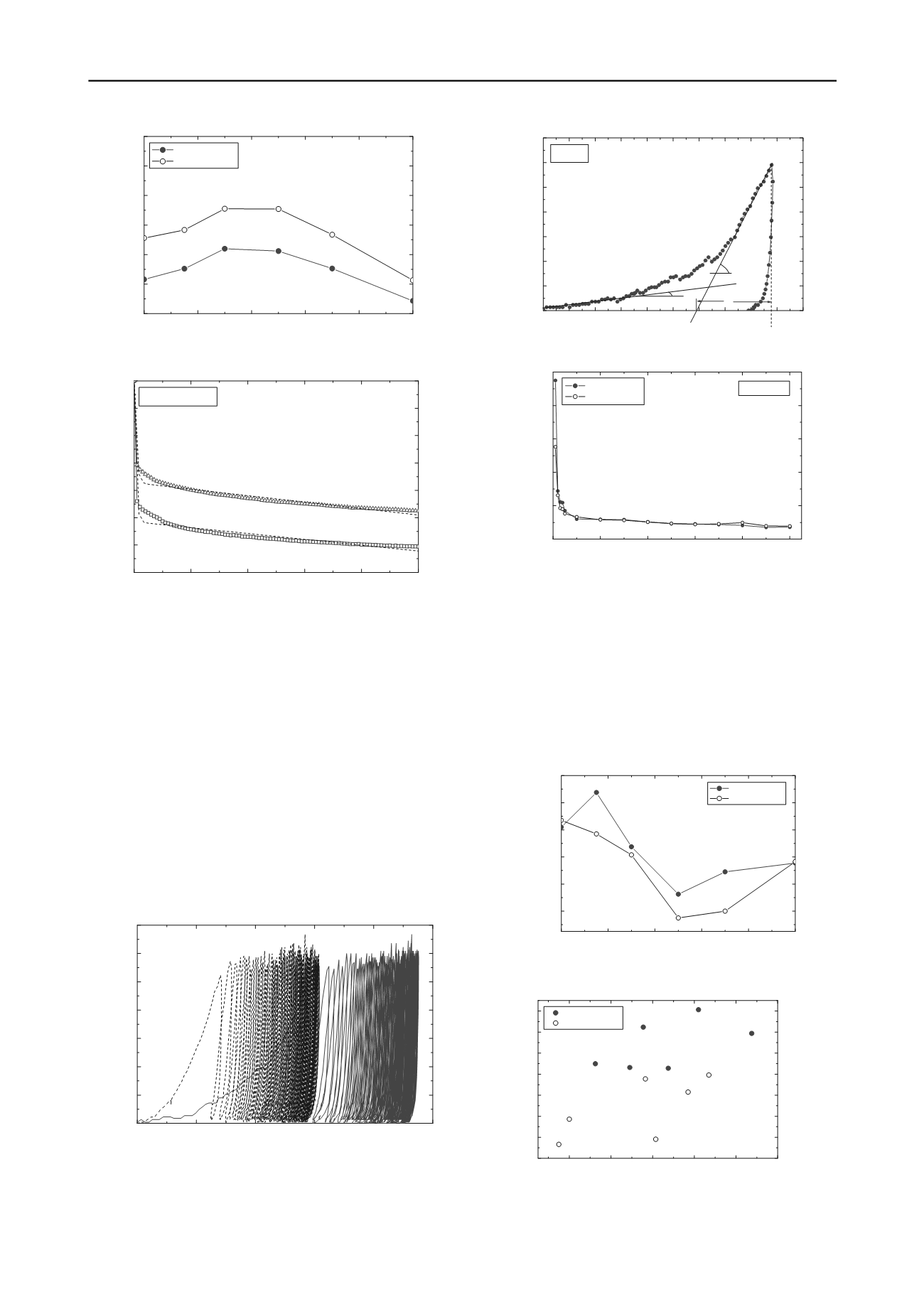

Figure 7. The settlement at 100 loading cycle vs. % sand

Figure 8. Relationships between

S

and

N

for fresh ballast and 30% sand

cases (before tie tamping application)

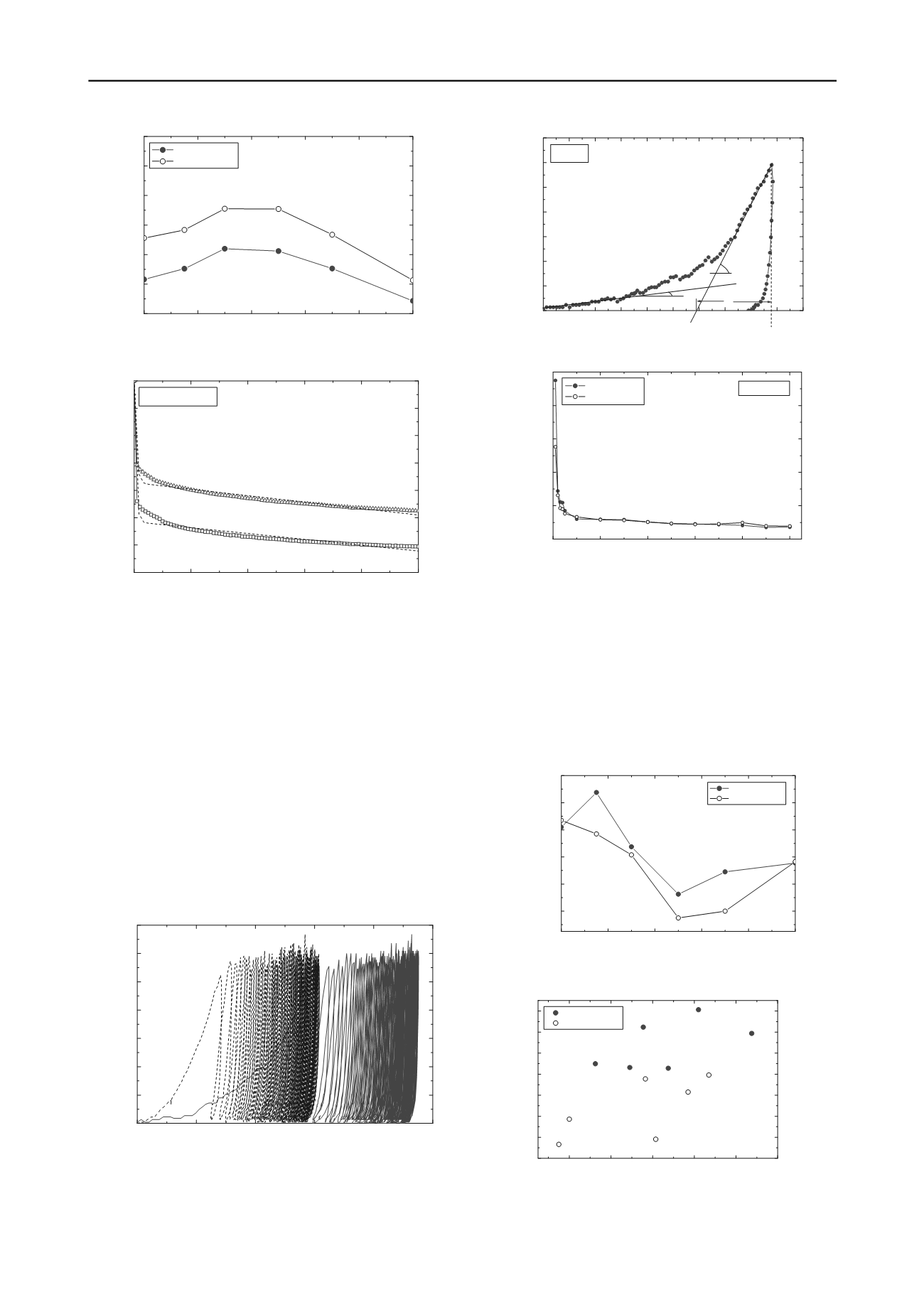

3.2 Effects of roadbed stiffness on settlement characteristics

Figure 9 shows typical relationships between sleeper settlement

and applied stress,

p

(30% sand case is shown here). It can

clearly be seen that settlement reduces in the 2

nd

phase (i.e.,

after tie tamping application), due to densification of the

specimen in the 1

st

phase (i.e., before tie tamping application

with 100 loading cycles).

In this research, the loading curves were fitted by bilinear lines,

and the slopes of the two lines were estimated as

k

1

and

k

2

as

shown in Figure 10. Displacement

u

2

was estimated by dividing

the applied stress by

k

2

as shown in Figure 10. The parameter

u

2

decreases and tends to show a constant value with

N

as shown

in Figure 11. Therefore, these constant values were used in the

following discussion.

Figure 9. Applied stress vs. settlement for 30% sand case

Figure 10. Calculation of

u

2

(Gravel specimen)

0

20

40

60

80

2.8

2.4

2.0

1.6

1.2

0.8

0.4

0.0

100

S

30%

= 1.49(1 - e

-1.44

N

) + 0.0047

N

S

0%

= 2.06(1 - e

-1.67

N

) + 0.0043

N

Before Tamping

30% sand

Fresh ballast

Settlement,

S

(mm)

No of loading cycles,

N

Figure 11. Relationships of

u

2

and

N

(30% sand case)

The relationships between

u

2

with %sand,

c

,

and

before and

after tie tamping application are shown in Figures 12-15

respectively. Figure 12 shows that 50% sand specimen is the

densest specimen (i.e., showing the smallest

u

2

). Figure 13

shows that

c

increases with

u

2

(though not very clearly),

indicating that loose specimen will result in higher initial

settlement, in both before and after tie tamping application.

Figure 14 shows that initial settlement period alter by tie

tamping application with a wider gap between the highest and

smallest

compared to those of before tie tamping application.

0

20

40

60

80

0.036

0.040

0.044

0.048

0.052

0.056

100

u

2

(mm)

Amount of sand (%)

Before Tamping

After Tamping

0.0

0.4

0.8

1.2

1.6

2.0

0

20

40

60

80

100

120

140

After tamping

Before tamping

Applied stress,

p

(kPa)

Settlement,

S

(mm)

Figure 12. Relationships of u

2

and% sand

0.036

0.040

0.044

0.048

0.052

0.056

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

c

u

2

(mm)

Before Tamping

After Tamping

Figure 13. Relationships of

u

2

and

c