1310

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

vary considerably, due to inherent differences between sites and

how the magnitude of improvement is both defined and

quantified. For example, Avalle and Carter (2005) reported a

depth of improvement to approximately 1.4 m in botany sands,

whereas Avalle (2007) reported a depth of 7 m in calcareous

sands. Additionally, time and cost constraints typically limit the

number of field tests that can be undertaken. In the case of

Mentha et al. (2011), there were requirements on the minimum

depth from the surface that cells could be placed to avoid

damage to the EPCs, as well as the minimum spacing between

adjacent EPCs to reduce stress shadowing effects. Such

arrangements provide physical limitations on the spatial

resolution of data that can be collected. As a result, contour

plots of vertical and lateral stress produced lack of resolution.

There is currently no employable theoretical model or robust

predictive model to accurately predict the depth of influence of

RDC, the energy imparted per blow or the effectiveness of RDC

on different soil types and site conditions. Moreover, there is

also limited published information from case studies to indicate

the optimal number of passes needed to attain the targeted soil

density for a given site or ground condition. A consequence is

that costly and time consuming field trials are inevitably

required before using RDC. Due to cost and time constraints

this can limit the usage of RDC in some projects.

2 NUMERICAL MODELLING

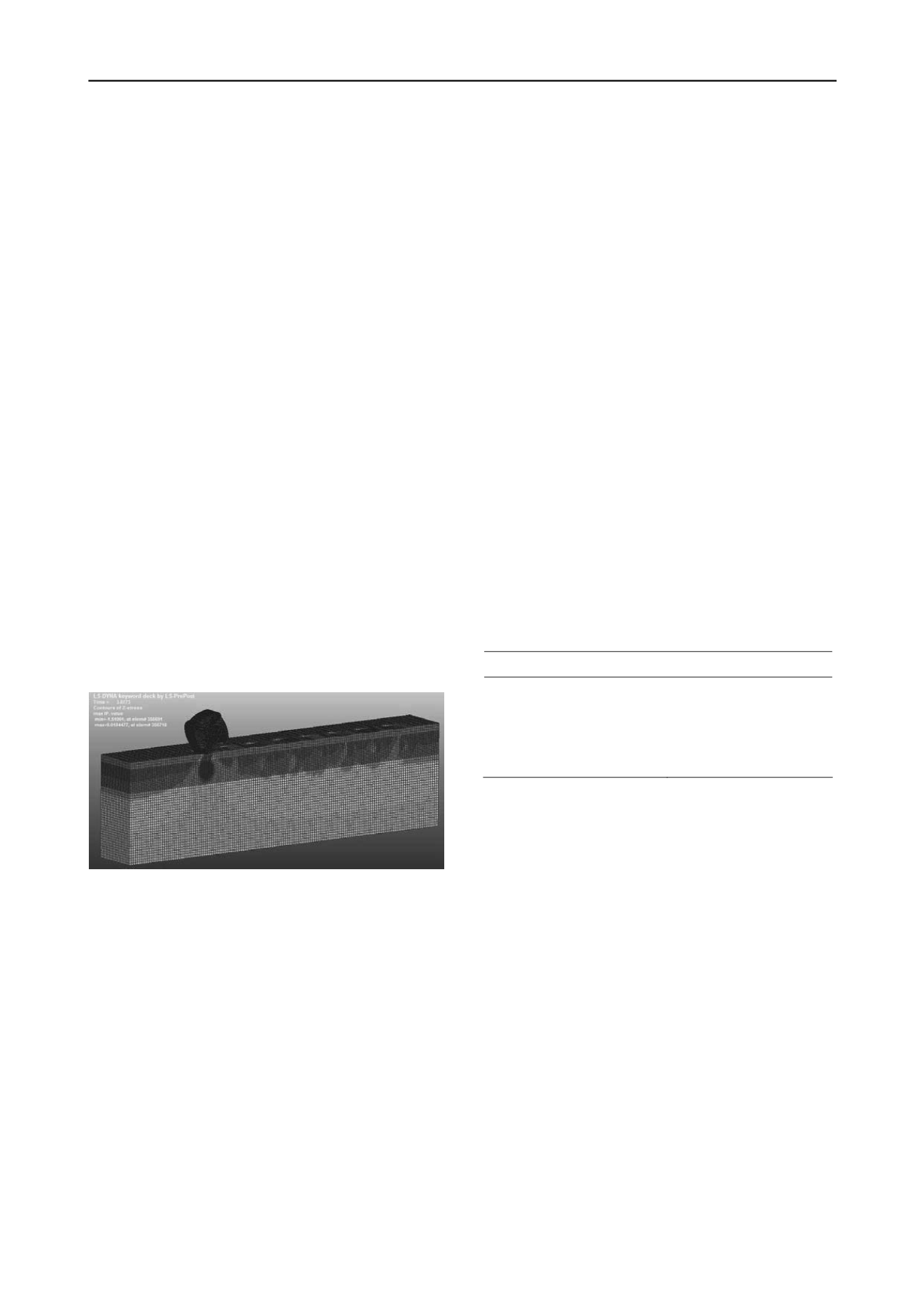

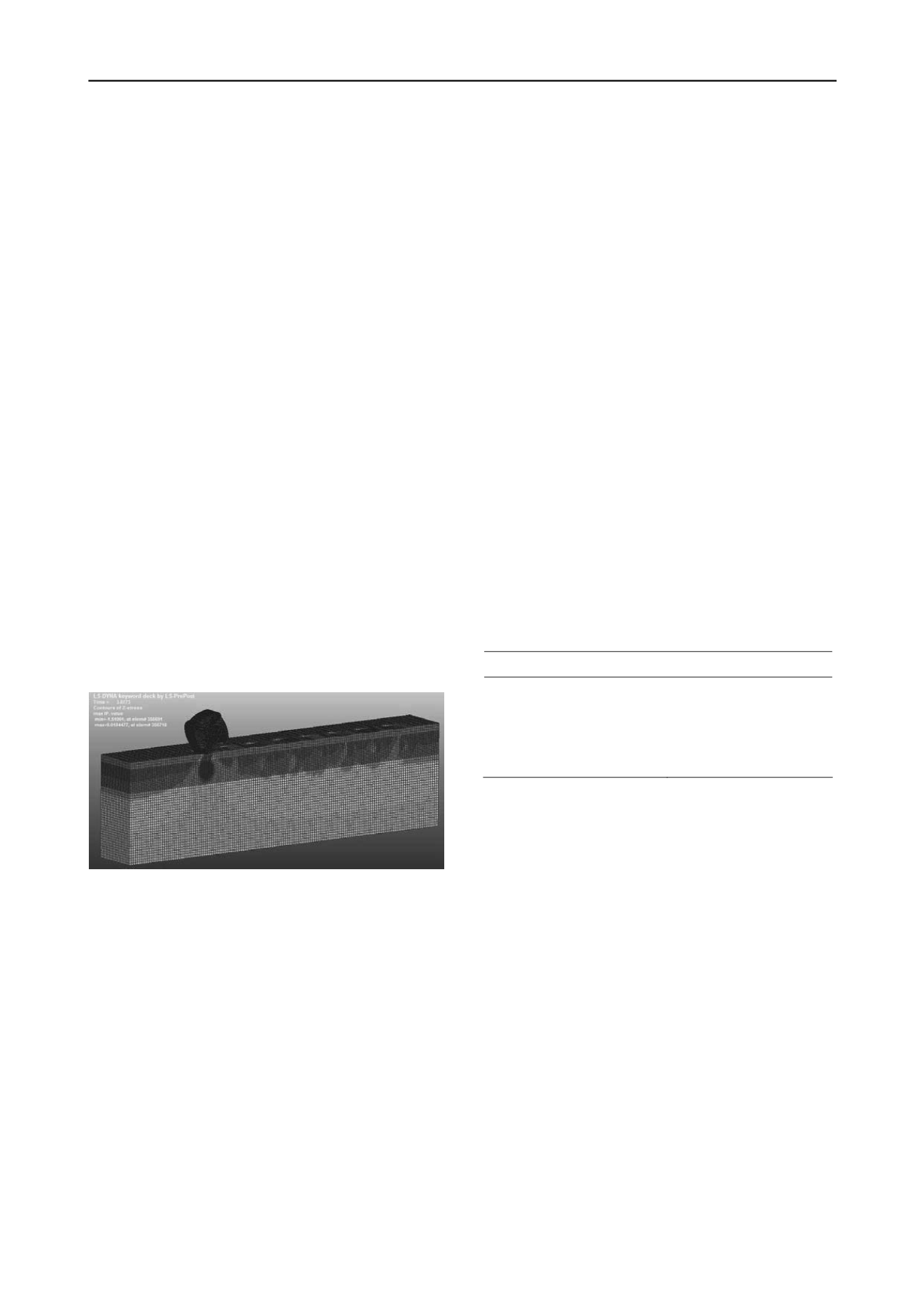

This research aims to fill the knowledge gap discussed

previously by evaluating the effectiveness of RDC using the

dynamic finite element modeling (FEM) software LS-DYNA

(Hallquist 2006). A 3D numerical model was developed that

allowed the rolling dynamics of the 4-sided impact roller to be

simulated. The model was then validated against field data

collected by Mentha et al. (2011). The adopted final FEM

model is illustrated in Figure 2.

Figure 2. FEM model.

The FEM model consisted of two major parts: the 4-sided

impact roller itself, which is a simplified model of the

Broons

BH-1300 roller

(Figure 1), and the soil mass. The module is a

steel encased concrete block. As it rolls, any deformation

caused by the impact on the roller is very small and negligible.

Therefore, it is reasonable to assume that the roller acts as a

rigid body. The model utilized shell elements on the roller,

whilst 8-node quadrilateral solid elements were used on the soil

mass. To simulate the confinement and far field conditions, LS-

DYNA boundary conditions *BOUNDARY_SPC_BIRTH

_DEATH and *BOUNDARY_NON_REFLECTING were

prescribed to the sides and base of the soil mass. Two of LS-

DYNA’s soil constitutive models were examined, namely the

MAT_005_Soil_and_Foam and the MAT_193_Drucker_and_

Prager models. It was found that the MAT_005 underestimated

the soil settlement caused by the roller and was therefore

excluded from further modeling. During the initialization stage

of the modeling, the effects of gravity loading were added using

*LOAD_BODY_Z and *LOAD_RIGID_BODY. The contact

definitions between the roller and the soil mass is described in

LS-DYNA’s *CONTACT_AUTOMATIC_ SURFACE_TO_

SURFACE_ID. Finally, the *BOUNDARY_PRESCRIBED_

MOTION_RIGID option was used to define the rolling motion

(both horizontal and rotational speeds) of the roller. A detailed

description of the FEM is given by Bradley et al. (2012).

3 FIELD WORK AND LABORATORY TESTING

The field work undertaken by Mentha et al. (2011) took place at

the Project Magnet Tailings Storage Facility at the Iron Duke

Mine, South Australia. The fill material typically consisted of

coarse iron magnetite tailings that are a by-product of a

consistent treatment process. The results from sieve analyses

and plasticity tests indicated that the soil is a well graded sand

(SW) with small quantities of gravel-sized material (14%) and

clay fines (6%) of low plasticity (LL = ~22%, PL = ~11%).

The average field moisture content was ~5% and the water table

was located well below the influence depth of RDC.

The test pad consisted of three lanes; three lift heights of

1200 mm were achieved. The EPCs were strategically placed at

various vertical and lateral levels. The EPCs were connected to

a data acquisition system and a laptop to continuously record

the pressures induced by the 8-tonne BH-1300 impact roller.

EPC data for the roller at rest (static case) and in motion

(dynamic case) were analyzed and reported.

Triaxial and direct shear testing was carried out by the

authors to complement the results from Mentha et al. (2011) to

characterize further the engineering properties of the tailings

material. The results for key soil parameters, which are essential

for MAT_193, are summarized in Table 1. The Poisson’s ratio

was assumed to be 0.3. These values were used in the

subsequent numerical modeling.

Table 1. Summary of laboratory test results for key soil parameters.

Soil parameters

Results

Cohesion (kPa)

7

Angle of internal friction (°)

37

Elastic shear modulus (MPa)

5.7

Mass density (t/m

3

)

2.55

4 VALIDATION OF FEM

Validations of the FEM focused on both static and dynamic

(single pass at 10.5 km/hr rolling speed) cases. In the static

case, the variations of influence stress with respect to depth

from the FEM model were compared with solutions derived

from classic Boussinesq theory and Fadum’s chart.

Comparisons are summarized in Figure 3. Note that, the

influence stress plotted is due to the impact roller only;

excluding the overburden pressure due to the soil’s self weight.

Moreover, the FEM predicted an immediate settlement of

4.4 mm, which is very close to the solution given by theoretical

elastic theory of 5.1 mm.

In the dynamic case, the FEM was validated against field

data collected by Mentha et al. (2011), and the results are shown

in Figure 4. The comparison showed that the FEM accurately

predicted the influence stress at various depths and exhibited a

smooth trend. The FEM also predicted an immediate settlement

of 17.8 mm after a single pass. Mentha et al. (2011) reported

settlement data after the 8

th

and 16

th

passes only. In order to

directly compare the results, approximations using linear and

quadratic trend fitting to the field data yielded 17.0 and

18.5 mm respectively for a single pass. The settlement

predictions from the FEM lay between these two values. In

summary, the results showed that the FEM is able to predict

accurately the influence stress and soil settlement in the static

and dynamic cases.