3062

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

2 EXPERIMENTAL PROGRAM

This research analyzes the hydration behavior of the GCL from

underlying soil under different field exposure conditions,

including daily thermal cycles before waste placement, and

constant temperatures induced by the waste decomposition after

waste placement. Also, the effect of normal stresses provided by

the overlying layers (e.g., Leachate Collection System (LCS),

cover soil) is investigated. The hydration progression of three

GCL products (GCL1, GCL2, and GCL3) which have

significantly different manufacturing techniques has been

evaluated in this study. Ontario Leda clay (CL in USCS

classification system, ASTM D2487), clayey sand (SC), silty

sand (SM), and ordinary construction sand (SP) were used to

investigate the effect of the subsoil grain size distribution on

GCL hydration. The hydration process was monitored by

measuring the gravimetric moisture content (i.e. mass of

water/mass of dry material) of the GCL up to 40 weeks.

2.1

GCL properties

GCL 1 and GCL2 contained fine granular sodium bentonite

with D

50

of 0.35 mm while GCL3 was coarse granular with D

50

of 1 mm. All GCLs had NW cover geotextiles. The main

difference of the GCLs was the connection layer and also the

type of the carrier geotextile (Table 1). GCL1 and GCL2 had

similar swell and plasticity indices of 24 ml/ 2g min. and 216%

(ASTM D 4318), respectively. GCL3 had a swell index of 23

ml/ 2g min. and plasticity index of 262%. The water retention

curves for these GCLs have been presented by Beddoe et al.

(2011). The submerged moisture content, i.e., the maximum

gravimetric moisture content which the GCL could attain while

immersed in water is also given in Table 1.

Table 1. GCL properties

GCL

Total dry

mass/area

(g/m

2

)

Carrier/

Cover

Geotextile

Connection

Layer

Submerged

Moisture

Content

1 4555-4988

W/ NW

NPTT

150±10

2 3312-4006

SRNW/ NW

NPTT

118±5

3 4499-5295

W/ NW

NP

190±10

W = Woven, NW = Nonwoven, SRNW = Scrim reinforced nonwoven,

P = Needle punched, NPTT = Needle punched and thermally treated.

N

2.2

Soil properties

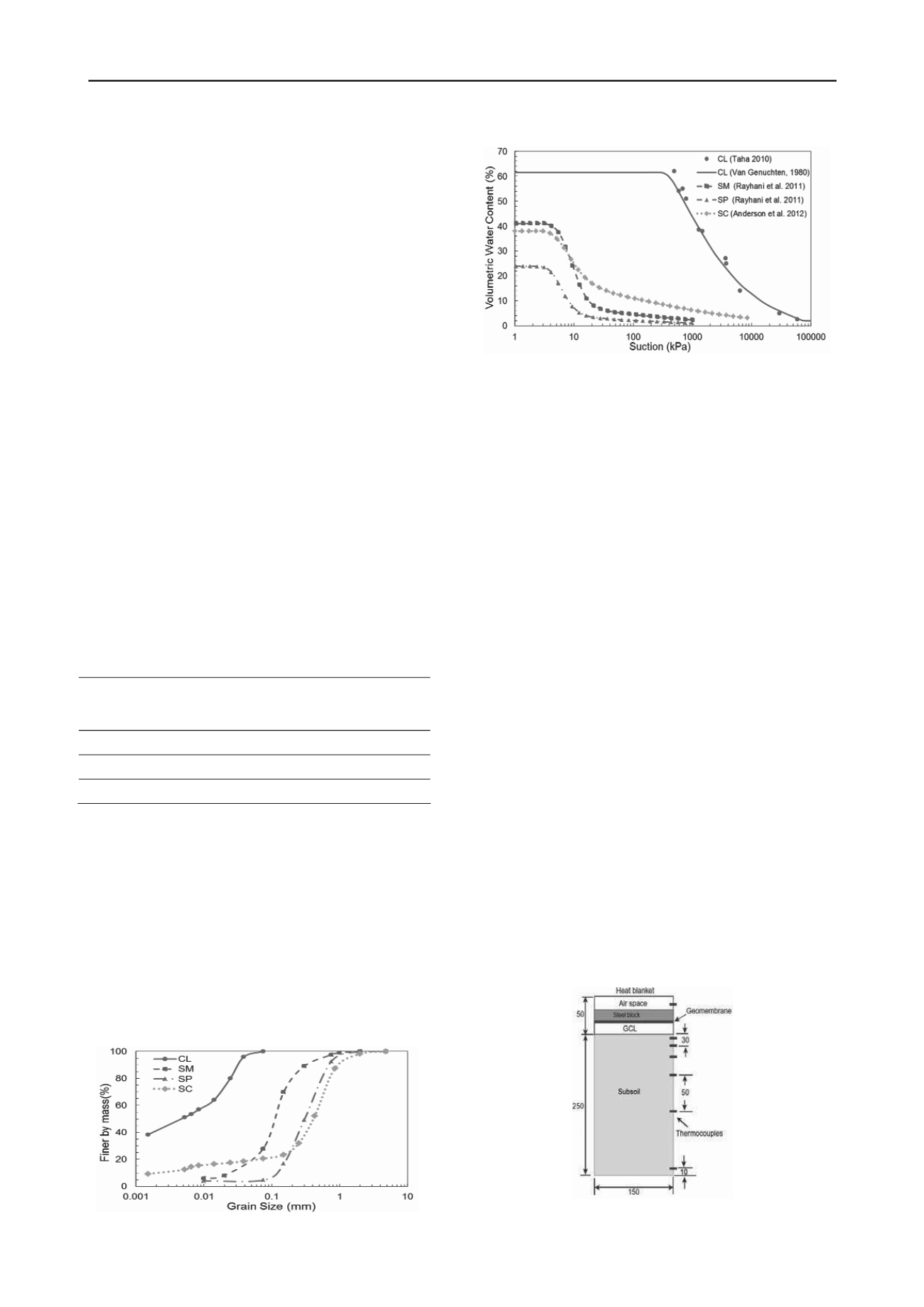

The basic geotechnical properties of the four subsoils were

determined through laboratory testing (Figure 1). The sand (SP),

silty sand (SM), and clayey sand (SC) contained 5%, 35%, and

21% fines passing through the 0.075 mm sieve, respectively.

The plasticity indices of the clay and the fine portion of clayey

sand were measured at 21.6%, and 4%, respectively (ASTM D

4318). The maximum dry densities of the sand, silty sand,

clayey sand, and clay were measured at 1.68, 1.83, 1.96, and

1.43 Mg/m

3

with the corresponding optimum moisture contents

of 10%, 11.4%, 11.3%, and 28.3%, respectively (

ASTM D 698

).

(a)

Figure 1. (a) Grain size distributio (b) matric suction curves for the

2.3

Sample preparation

am of instrumented test cells

2.4

Experimental procedure

ct of constant temperature on

i

y

n and

subsoils examined.

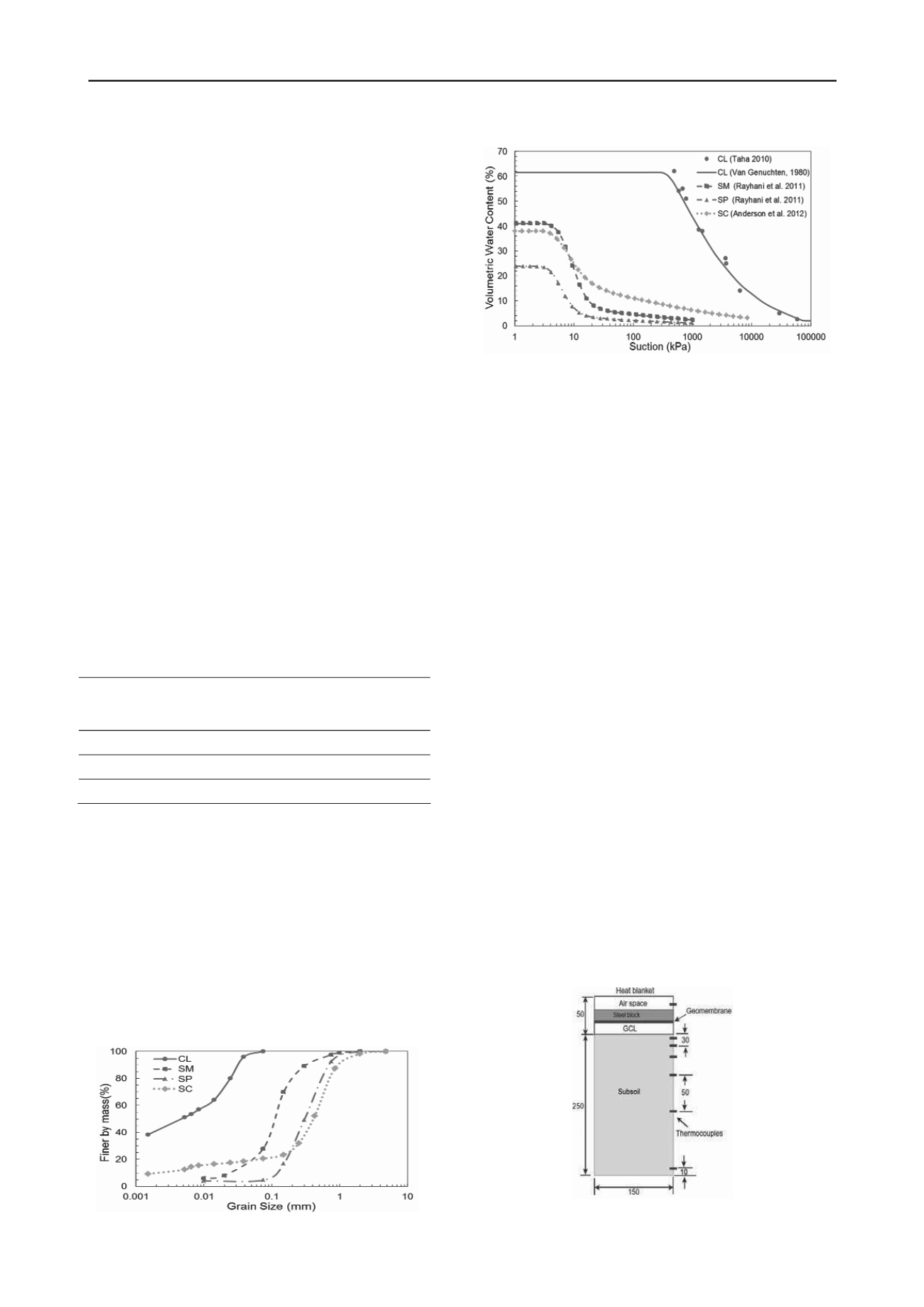

Figure 2 demonstrates the diagr

used for simulating GCL hydration from subsoil. To simulate

the profile of a composite liner, the soil under examination was

placed in cells having a diameter of 150 mm and a height of up

to 500 mm. Tap water with an average calcium concentration of

40 mg/L was mixed with bulk samples of dried soils to the wet

of optimum moisture content (

w

opt

+ 2%). Some soil samples

were watered to other gravimetric moisture content to evaluate

the effect of the initial moisture content (10%). The soil samples

were wrapped in airtight plastic bags to cure overnight.

Afterwards, the soil was compacted into the PVC cylinders in

five layers with a final height of 250 mm, and a dry density

corresponding to approximately 90% of the maximum dry

density. The GCL sample was placed over the subsoil and

overlain by geomembrane. A steel seating block with a known

weight corresponding to a specific level of normal stress (0-8

kPa) was placed on the liner. The test cells were closed and

sealed to prevent any loss of moisture, and were opened weekly

to determine the mass before returning them to the cells.

In order to investigate the effe

GCL hydration after waste deposition, heating blankets set to

the temperatures of 35, 45, and 55

C were placed on top of a

series of test cells. Some cells were left in room temperature

(22

±2C) for isothermal and control experiments. Also, heat

was applied for 8 hours to the top of some cells before they

were subsequently left in room temperature (22

C) for 16 hours

to simulate daily thermal (heating and cooling) cycles induced

by solar radiation. The sides of all cells were surrounded by

fibreglass insulation while their bottom was maintained at room

temperature to simulate vertical thermal gradients developed in

the field. Also, after 6 weeks of daily thermal cycles, the heating

cycles were brought to a halt for a period of 6 weeks to simulate

seasonal cooling periods before they were resumed.

F gure 2. Diagram of instrumented test cells used for simulating GCL

dration from subsoil (numbers in mm)

h