2443

Technical Committee 211 /

Comité technique 211

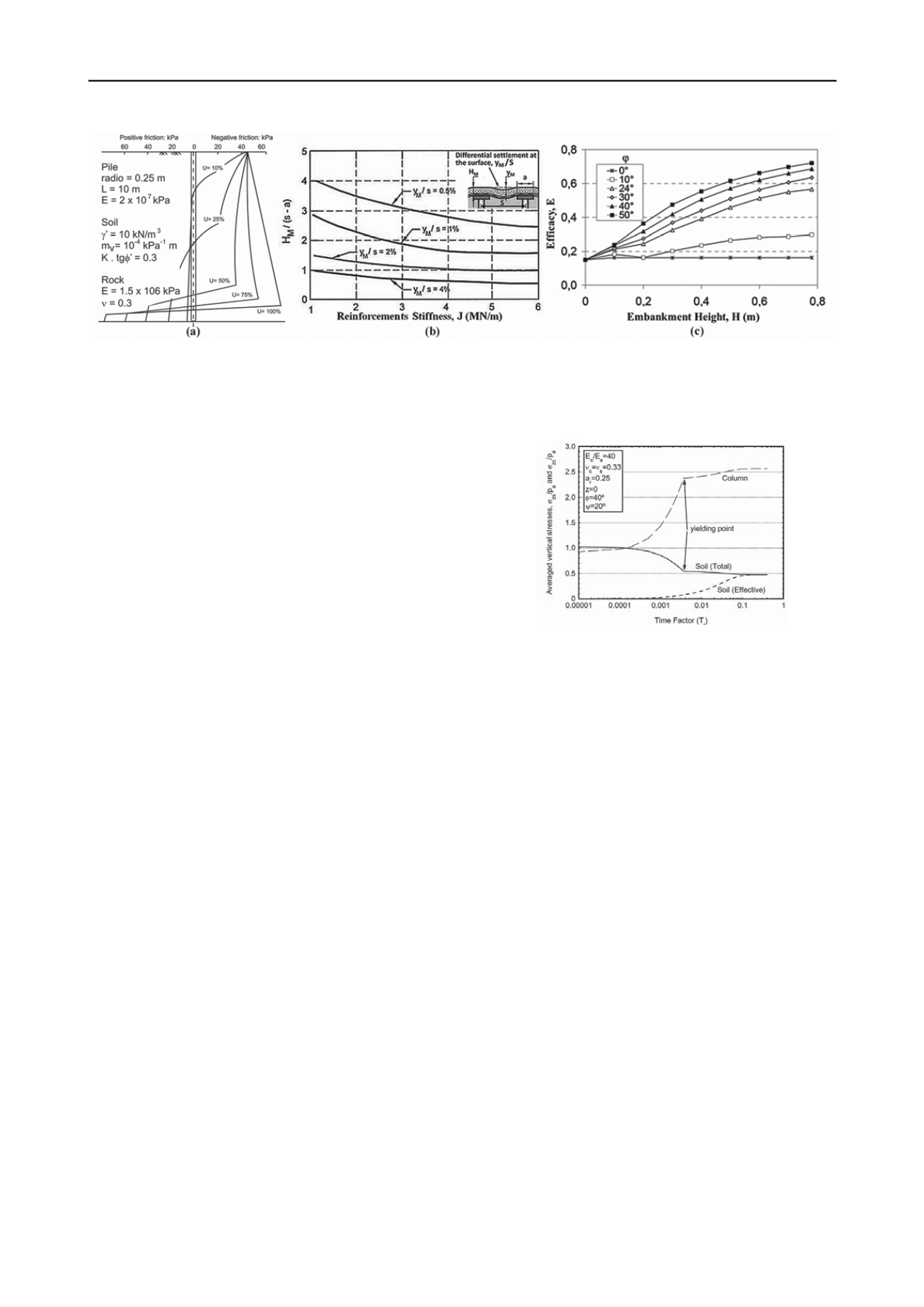

Figure 4. (a) Estimation of evolution of negative skin friction with degree of consolidation (Alonso et al. 1984); (b) chart for geosynthetic design

based of allowable differential settlement (Lawson 2000); (c) influence of height and friction angle of embankment on Efficacy factor (Jenck 2005).

deformation in the head of rigid inclusions may suppose the

failure state, as settlements may reach levels corresponding

tolarge percent of column diameter. Furthermore, the punching

failure in the head and toe of columns occurs immediately after

the application of embankment load, and associated risk

increases with smaller diameters of rigid inclusion, being quite

sensitive to the variation of the soil parameters also.

On the other side, flexible elements like stone columns tend

to reduce the punching effects at the base of embankment. In

this case the system gives a ductile behavior, whereas, due to

column compressibility and its drainage characteristics, the

ultimate limit state is reached after large deformation and at the

end of consolidation. Therefore, the behavior of such system

takes place in the domain of serviceability limit state (SLS).

Wehr et al. (2012) proposed three categories of increasing

risks, in order to assess the reliability of ground improvement

methods according to their ductility and sensitivity to the

variation of soil and materials parameters, taking as a reference

the standards DIN 1054 and Eurocode 7. Thus, regarding to

columns-type elements, flexible columns with small risks (stone

columns, vibro compaction, sand columns) are in category A;

rigid columns with diameter larger than 30 cm, which presents

an average risk, are in category B; and rigid inclusions with

diameters less than 30 cm and non-ductile behavior, which

represent a high risk, are in category C.

3.2 Consolidation process

The addition of cement agents disables the drainage capacity of

rigid columns, whereby settlements stabilization is obtained

only due to a high load concentration on the columns. However,

during the consolidation of pore pressures produced by the

remaining part of embankment load that act on the soil, an

important negative skin friction is generated in the part of

columns above the neutral plane, very similar to piles, but

without any capacity and structural connections. Consequently,

the risk should be assessed due to possible reduction or loss of

the load concentration on columns (or efficiency factor) along

the lifetime of the CSEs. This situation could occur if certain

loss of arching effect happens, as a consequence of possible

LTPs deteriorations, e.g. due to internal failure of geosynthetic-

reinforcement. In this case, the consolidation would occur in the

long term, according to the permeability of the natural soil.

Moreover, it would involve the evolution of neutral plane

over the time, dominated by the increase of negative friction.

Figure 4a shows an example of this complex mechanism

reported by Alonso et al. (1984).

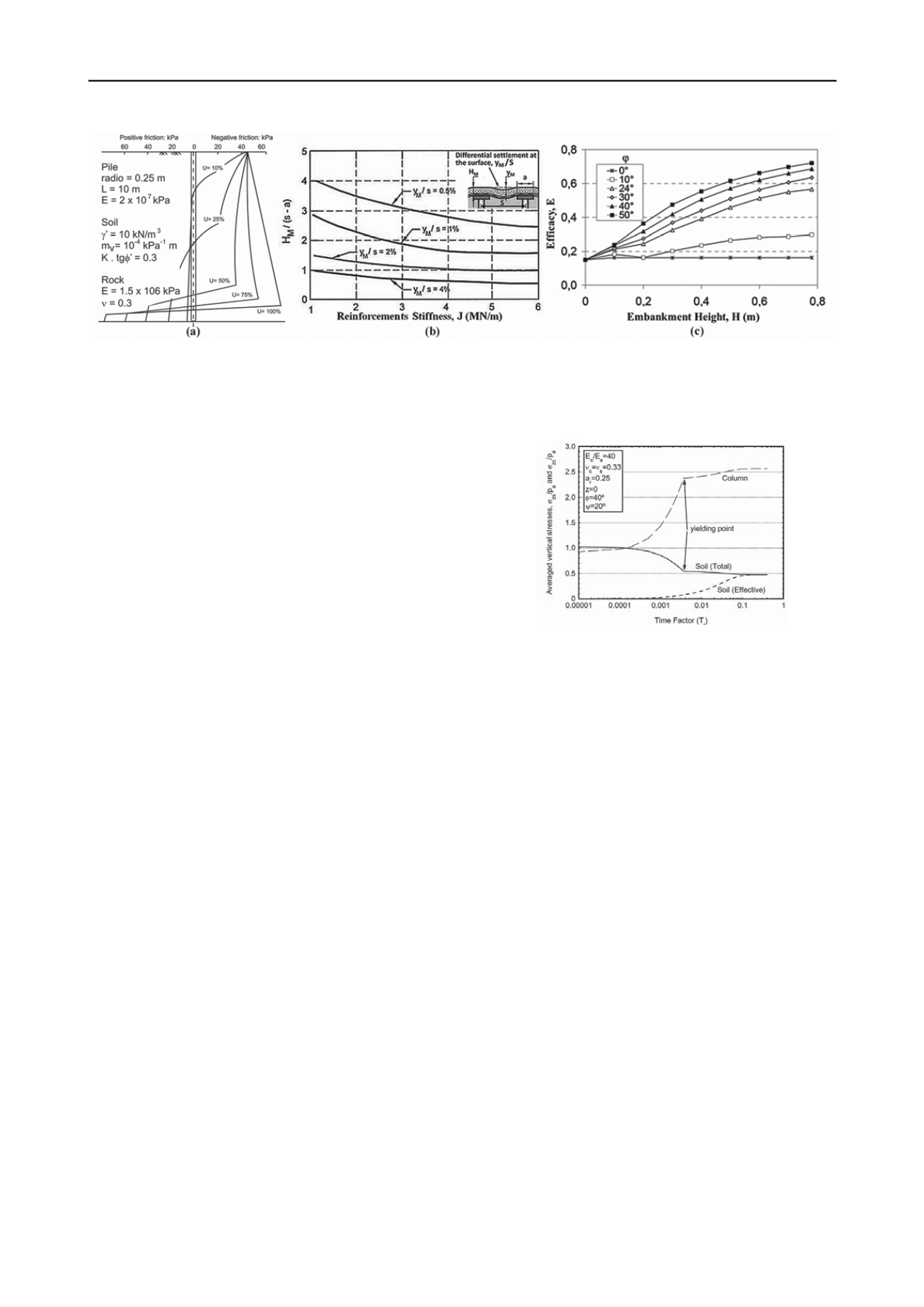

In the case of stone columns, the rapid settlements

stabilization is expected due to their drainage capability. Castro

and Sagaseta (2009) analyzed the evolution of stress

concentration on the stone columns, showing that in the very

beginning entire load is carried by the soil, and the final load

concentration on the columns is obtained after consolidation

(Figure 5). However, after short period of consolidation,

effective stress of soil tends to increase, and additionally

provides greater confinement to the columns. Such results

suppose an improvement of the whole column-soil system.

Figure 5. Time development of soil and column stresses, (Castro and

Sagaseta 2009)

4

GENERAL ASPECTS OF SAFETY VERIFICATION

There is a range of recommendations that attempt to unify

design of LTPs composed by geosynthetic-reinforcement layers,

basically used in piled embankments (BS8006 2010, EBGEO

2010, Nordic Handbook 2005). However, the design of column-

type elements is redirected to typical pile standards. As it was

mentioned in section 2.2, it has to be emphasized, that these

recommendations deal with systems where almost entire load is

transferred to bearing elements heads, hence negative skin

friction is practically negligible. According to what has been

stated here about the higher level of risk exhibited by the rigid

inclusions with small diameter, the most important safety

aspects of such elements will be commented.

4.1 Large-height embankment

The ASIRI recommendations define two different situations:

Domain 1: if the ULSs are not guaranteed without

improvement, rigid inclusions are used to ensure the global

stability, and bearing capacity of rigid inclusions for both ULSs

and SLSs have to be checked, similarly to the French Eurocode

7 application for piles.

Domain 2: if the ULSs are analyzed for the situation without

improvement, then rigid inclusions are used as settlement

reducers, and only SLSs have to be proceeded.

Taking into account the ASIRI recommendations, it could be

distinguished that when the CSE system comprises

embankments with more than 3 to 5 m height, the design is

usually focused to guarantee the ULSs. Regarding to the

external bearing capacity (GEO) for rigid inclusions, the most

important checks against the permanent loads will be punching

at their heads and tips, as well as the horizontal stresses,

bending moments and shear stresses due to slope

failures.Buckling effects have to be checked when soft soil has

pressuremeter modulus smaller than 3 MPa.