2435

Technical Committee 211 /

Comité technique 211

4

IN SITU TESTS

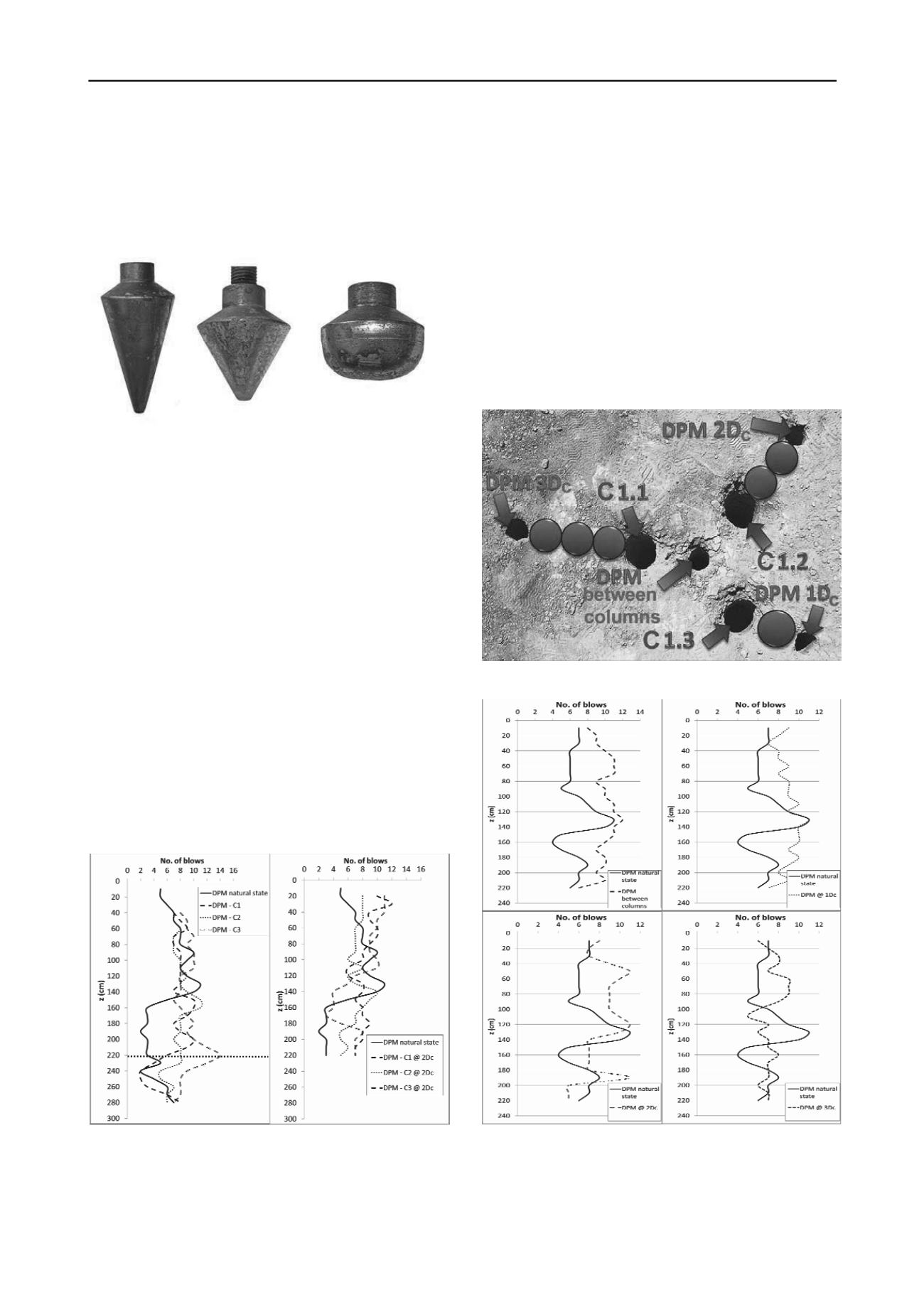

In-situ tests first aimed at identifying the effect of the cone

shape on: the rate at which the cone advances in the ground, the

tamping of the surrounding ground and the compaction degree

of the material in the column body. Three types of cones with a

diameter of 7 cm were made. (Figure 5).

Figure 5. Cones made: a) C1 – 30°; b) C2 – 60°; c) C3 – hemisphere.

4.1

Column execution technology

Collapsible soils improvement by soil columns is regulated by

normative C29 - 85. The experimental polygon met the column

execution methodology described in the normative but adapting

it to the equipment that has been newly proposed for their

execution (LMSR-Hk dynamic penetrometer).

Column execution steps are: column hole execution, filling

by fill material portions and fill material compaction until

rejection.

The fill material portion was set for a column with a

diameter of 7 cm and for a height of the compacted material of

21 cm (3 diameters), resulting 1,5 kg of material having optimal

compaction humidity.

Successive tests regarding the obtained compaction degree

indicated that rejection (compaction stopping) was reached after

an advance of maximum 7mm/blow.

4.2

Optimal cone shape

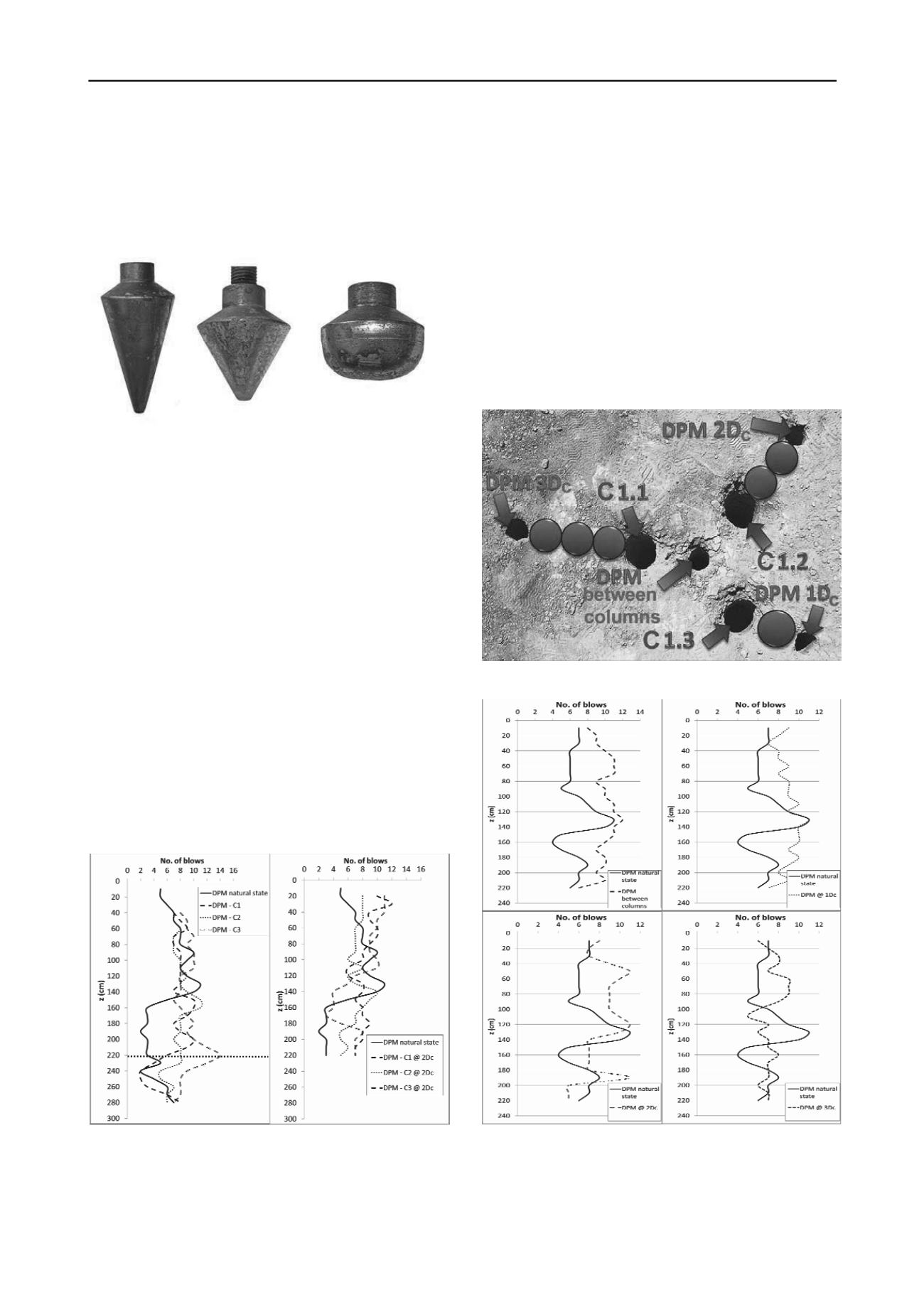

On the experimental polygon, columns were executed by using

the three types of cones. Figure 6a presents the blow number

variation per an advance of 10 cm in DPM tests performed in

the centre of the columns and Figure 6b presents the same tests

carried out at a distance of 2 diameters towards the column.

Figure 6. Results of DPM tests carried out in the centre of the columns

and at a distance of 2Dc (14cm) towards the columns.

In case of DPM tests carried out in the centre of the columns,

the results obtained were similar for all the columns. Therefore,

an optimal shape of the cone that leads to a better compaction of

the column body could not be found.

Then, for determining the cone with a wider influence

radius, DPM tests were carried out at a distance of 2Dc=14 cm

towards the columns. These tests indicated [as expected given

its shape (the smallest angle at the top)], that cone no. 1 (30

0

)

had the greatest influence on the tamping state of the soil

around the column.

The tests indicated that cone 1 shape (30°) was optimal for

soil columns execution.

4.3

Compacted loess columns

Therefore, 2 m long columns were executed, arranged as an

equilateral triangle network (Figure 7) with a distance of 3Dc -

21 cm

After finishing the group of columns, average dynamic

penetration tests were conducted both between the columns and

at different distances towards them.

between the columns.

Figure 7. Columns and DPM tests disposal.

mns; b) @ 1Dc;

Figure 8. DPM tests results: a) between the colu

c) @ 2Dc; d) @ 3Dc.

It may be observed that, at a distance of 3Dc near the

columns, the improvement effect has no longer been perceived

(Figure 8d). When the DPM test was carried out in the centre of

the column group (Figure 8a), the improvement effect recorded

an obvious increase.