2438

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

build models and the Z_Soil software was used for

computations. An elastic – ideally plastic model of Coulomb –

Mohr boundary surface with non-associated law of flow were

adopted to describe the mechanical behaviour of the soil

environment and the jet grouting columns material.

To perform computer simulations it is necessary to give the

following parameters: angle of internal friction

Φ

, angle of

dilatancy

Ψ

, cohesion

c

, modulus of elasticity

E

and Poisson’s

ratio

ν

. Values of parameters for soils building the model

subsoil were taken based on in situ tests on a test site. The

following values were taken, for sand:

E

= 55.5 MPa,

ν

= 0.3,

Φ

= 31.8°,

c =

1 kPa, for a cohesive soil interbedding:

E

= 33.8

MPa,

ν

= 0.3,

Φ

= 18.0°,

c =

30 kPa. The value of angle of

dilatancy was introduced from the range of values

Ψ

=

(0.35÷0.40)·

Φ

. Determination of material parameters for a

cement

soil material depends on the subsoil ground

characteristics, cement type in the grout, the method of columns

performance. To determine them it is necessary to take core

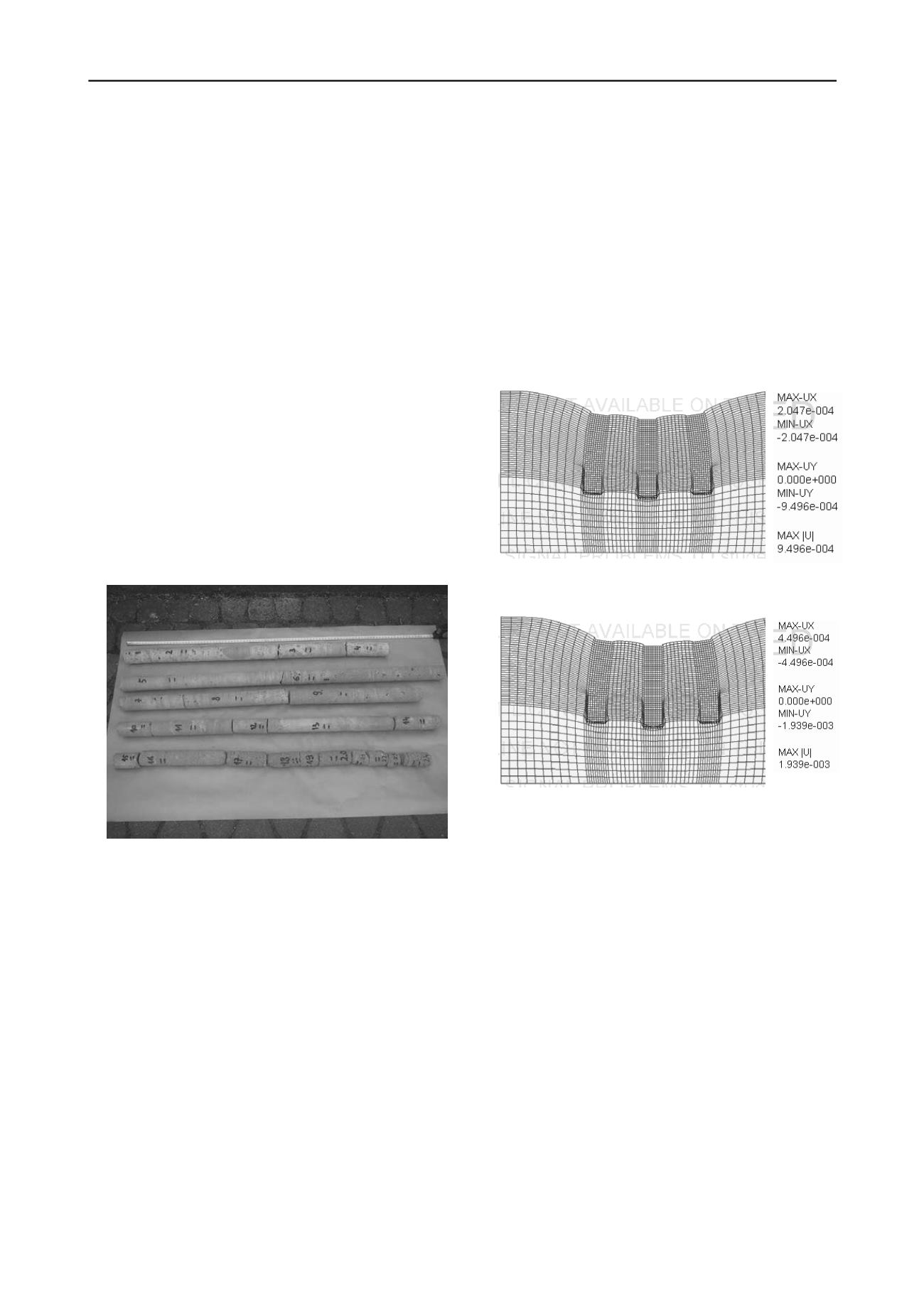

samples from the column performed (Fig. 1). These samples are

then tested for uniaxial and triaxial compression. For the needs

of this study 10 samples were tested for each case, obtaining

results of significant scatter (Bzówka 2009). A statistical

analysis of result values was carried out and after approximation

with the first type regression function the following parameters

were taken for calculations:

E

= 9888 MPa,

ν

= 0.186,

Φ

=

59.3°,

c =

1772 kPa. Values of soil parameters

(E

,

ν

,

Φ

,

c

) were

taken for the contact zone based on CPT sounding performed in

this area. Their values equal to soil parameters reduced by 1/3.

Figure 1. Core samples for strength tests (Bzówka, 2009).

A 2D model was built cutting from the space around

columns an area large enough, allowing idealisation of

boundary conditions. Boundary conditions were taken in the

form of: full fixing of the base of the half

space cut and partial

fixing, allowing a vertical shift, on side surfaces of the half-

space

In the model of a flat system a group of 3 columns was

taken, each of them 4.0 m long and 0.8 m in diameter, arranged

at a distance of 2.5 m, while the subsoil is stratified. Division

into quadrilateral isoparametric elements was assumed. The grid

was concentrated in the area of contact zone. An incremental

load (uniform for all columns) was applied to such system,

reflecting a real transport embankment 4.0 m high, laid at fixed

intervals in layers 0.5 m thick.

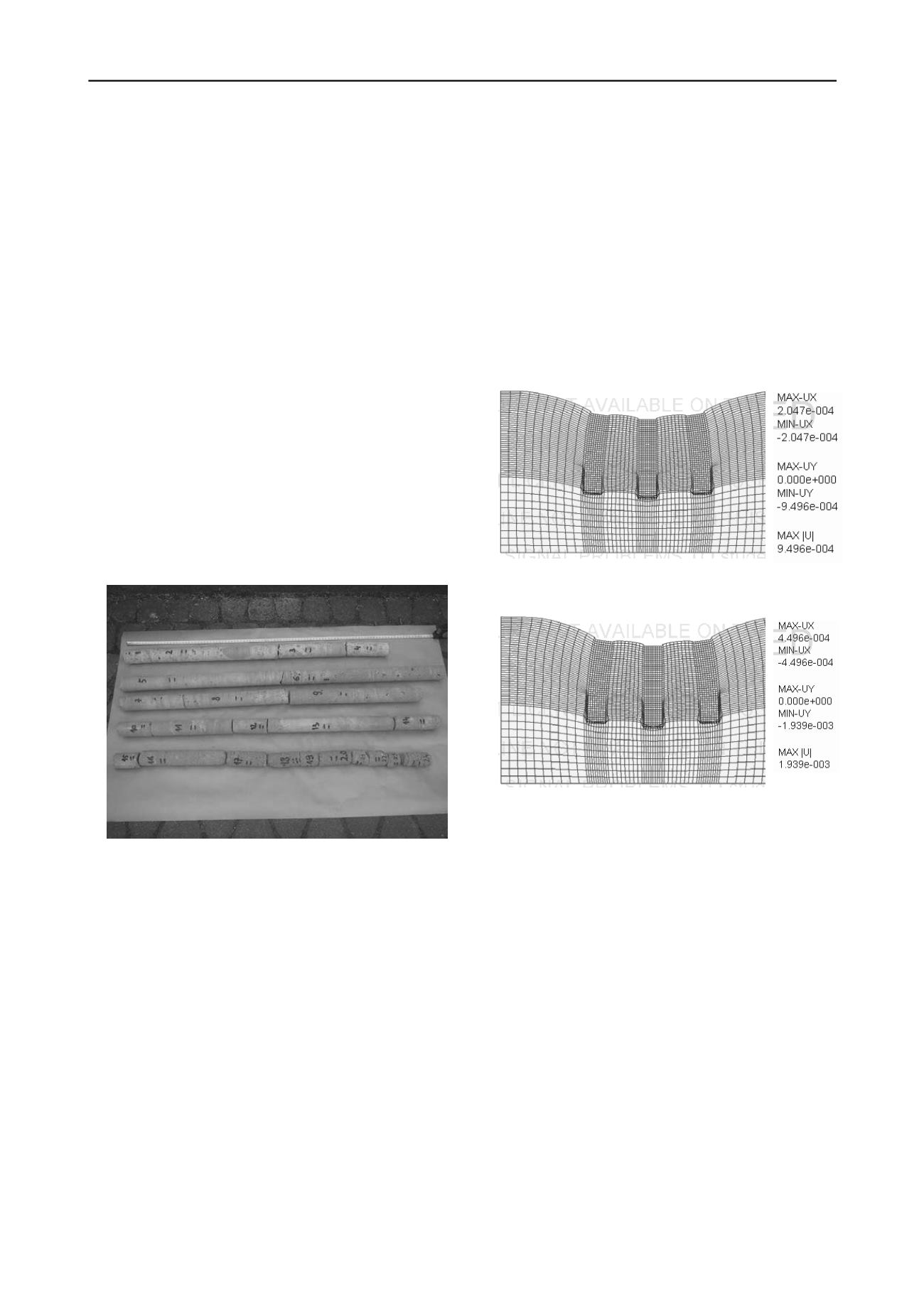

The image of system deformations caused by columns

loading is presented for two stages in Fig. 2. Corresponding

stresses are shown in Fig. 3. The stress maps perfectly show the

range of transition zone, which parameters affect the

distribution of internal forces values in the system (Bzówka et

al. 2012; Juzwa 2012a).

2 GEOMETRY OF JET GROUTING COLUMNS

The shape of columns made by the jet grouting technique, due

to specific nature of this technology, is very diversified and

difficult to predict. It depends inter alia on the type and

condition of soils making the subsoil, the injection system used

(single, double or triple) and on technological parameters

(injection pressure, size and shape of injection nozzles, speed of

injection rod pulling out and rotations and others) (Wanik and

Bzówka 2012).

To determine precisely the geometry of jet grouting columns

they are excavated, making their measurement and macroscopic

visual inspection possible. The shaft may have various shapes

(Fig. 4) depending on the aforementioned factors.

a)

b)

Figure 2. Model deformations [m] under influence of the load of

embankment: a) h=2.0 m; b) h=4.0 m high (Z_Soil) (Bzówka et al.

2012; Juzwa 2012a).

Fractal theories may be used to describe an irregular surface

of jet grouting columns. Using a fractal and a box dimension it

is possible to describe better an irregular shaft surface of a jet

grouting column, its shape and roughness. A more precise

description of roughness and geometrical parameters of soil

particles allows a more detailed determination of such

properties as: porosity, density and shear strength (Bzówka and

Skrzypczyk 2011).

The paper presents an example of fractal dimension and box

dimension calculation for an excavated jet grouting column

made in a single system (see Fig. 6÷8). Results of studies

presented in papers (Kawa and Wieczorek 2005; Wanik 2012a,

2012b; Wanik and Bzówka 2012) have been used.

The described jet grouting column was made in average

compacted medium sand, under which a stiff silty clay was

situated. After column excavating and cleaning, an irregular

shaft surface was disclosed and also a clear change of column

diameter on the boundary of two layers forming the subsoil (see

Fig. 5).

a)