1744

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

2 COMPENSATION GROUTING FOR SHALLOW

FOUNDATIONS

Compensation grouting is frequently applied in urban tunnelling

projects to reduce the impact of tunnelling to adjacent buildings

providing the advantages of an active protection measure

according to the observational method. For a detailed

description of the compensation grouting method see Falk and

Kummerer (2012). In the particular case of Metro B1,

compensation grouting substituted the original design with full

face (jet) grouting of the cross section for the following reasons:

reduction of space requirements as all activities were

located within small shafts and one site installation area

no additional area needed to provide the space for drilling

rigs (e.g. on roads closed for traffic)

simple drilling geometry with two parallel grouting pipe

(TAM) arrays avoiding complex 3D drilling set-ups

reduction of spoil resulting from jet grouting

real-time monitoring of critical buildings with the

possibility of actively correct undue deformations.

Before implementing compensation grouting for 8 critical

buildings close to ‘Bologna station’, the actual state and

tolerable deformations of these structures were assessed in

comprehensive studies. The allowable maximum absolute and

differential settlement was defined with 15 mm and 1/500,

respectively. Deformation analyses based on the well-known

soil behaviour showed that for the assumed volume loss of 0.6

to 2.0% (with a tunnel diameter of 6.8 m) settlements would

exceed the allowable value. To prove the efficiency of

compensation grouting, a full-scale field trial under similar

conditions was performed demonstrating that a controlled heave

of an isolated footing of 4 cm was achieved after a cycle of

repeated controlled grouting steps with special cement based

grout mixes. For a detailed description of the design and the

field trail see Sciotti et al. (2011).

The grouting strategy identified by means of the field trial

was applied to these building protected by 197 TAM pipes

installed on a ground surface of approx. 3,000 m². All buildings

were pre-heaved by max. 5 mm to prove the immediate reaction

for concurrent grouting. To guarantee high accuracy drillings,

all TAMs were installed with the Horizontal Directional

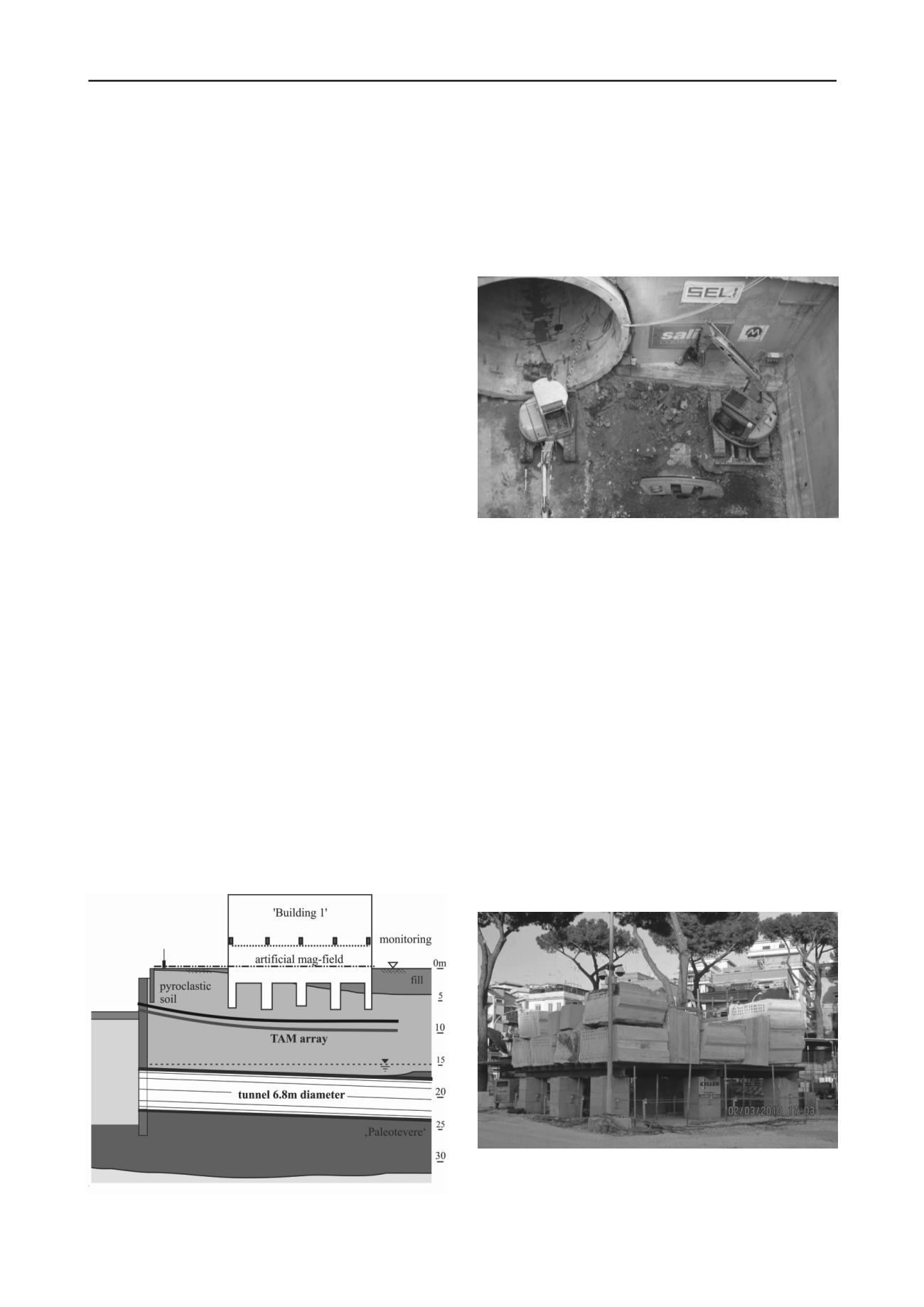

Drilling-Technology. For ‘Building 1’ the grouting pipes had a

radius of 120 to 140 m (see Fig. 3). Although the minimum

distance of the TAMs was less than 1 m from the foundation, no

significant settlement was measured during drilling.

Figure 3. Cross section of compensation grouting for ‘Building 1’.

In total, more than 100 monitoring points were installed for

controlling the compensation grouting operation with a zero

reading before any activity on site.

As all grouting parameters (e.g. TAM spacing, grout mixes,

injected volumes) were tested during the field trial, the grouting

operation was very efficient during the excavation of both

tunnels. The settlements were below the tolerable values. Fig. 4

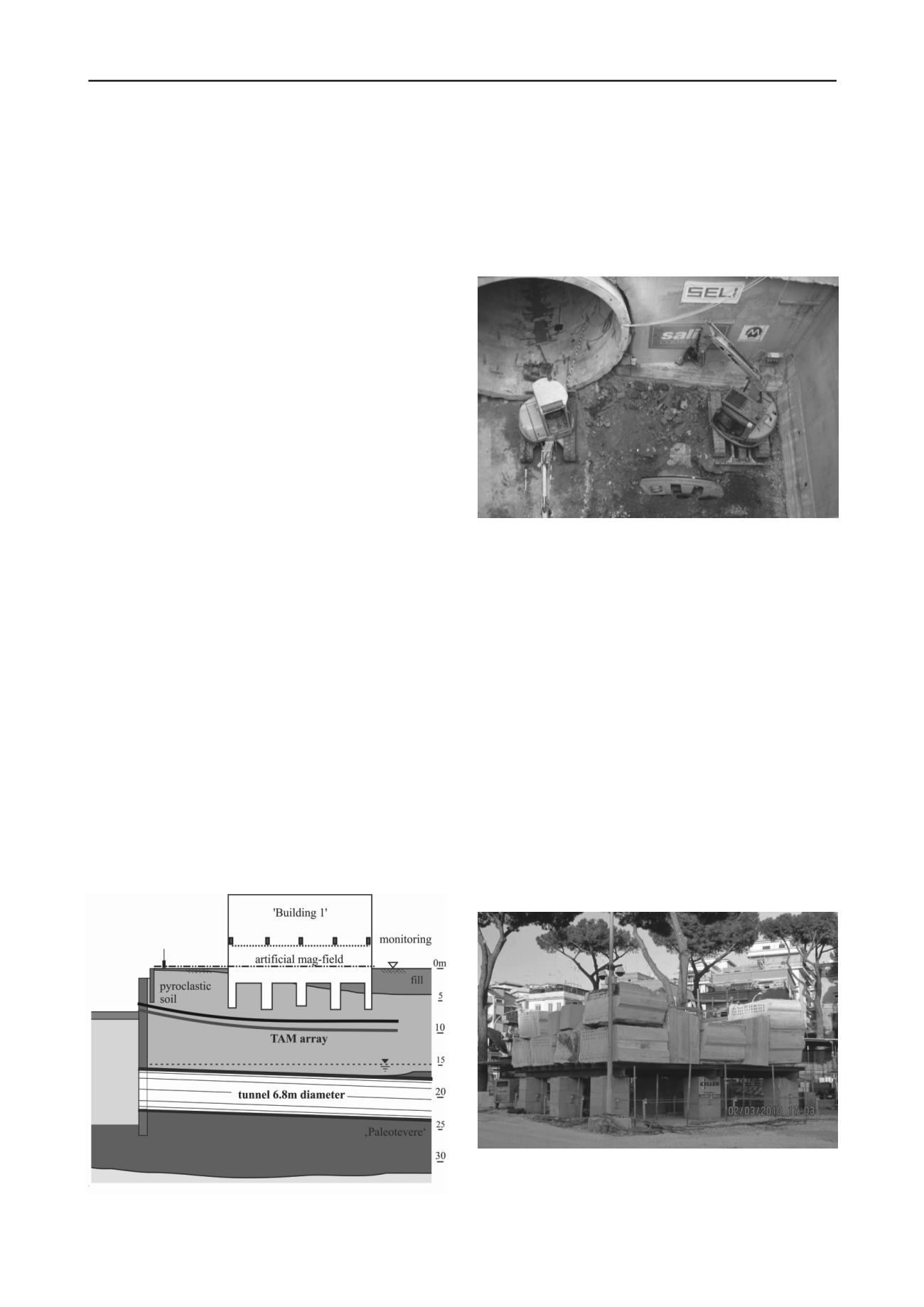

shows both tunnels from the final station shaft.

Figure 4. Picture of finished upper tunnel and TBM in end position for

lower tunnel.

3 COMPENSATION GROUTING FOR PILED

FOUNDATIONS

Compared to the conditions of the above mentioned works with

relatively shallow foundations, circumstances were different at

‘Ionio Station’ (Kummerer et al. 2012). The tunnel diameter

was 9.8 m (double track tunnel). The grouted and excavated

soils were gravels with a low content of fines. And more

important, all buildings are founded on piles with a typical

diameter of 600 mm and a pile length of max. 19 m. Therefore

additional studies were necessary to address the very complex

situation of compensation grouting for piled foundations.

As a consequence and due to the fact that worldwide only

limited experience was available for grouting underneath piled

foundations, an additional real-scale field trial was performed.

For the trial an already excavated station was chosen

representing conditions similar to the actual compensation

grouting works. A dead load of approx. 50 kPa above 9 piles

with a length of 15 m and 20 m respectively represented the in-

situ conditions (see Fig. 5).

Figure 5. Photo of ‘Ionio Station’ full-scale field trial.

Fig. 6 shows the schematic cross section of the field trial

with ballast, piles and monitoring (liquid levels, pressure cells,

precise levelling and incremental extensometers).