1749

Technical Committee 204 /

Comité technique 204

0

30

60

90

120

150

180

0

2

4

6

8

1

v

(kPa)

h

(m)

0

overburden

90°

80°

70°

60°

50°

40°

30°

20°

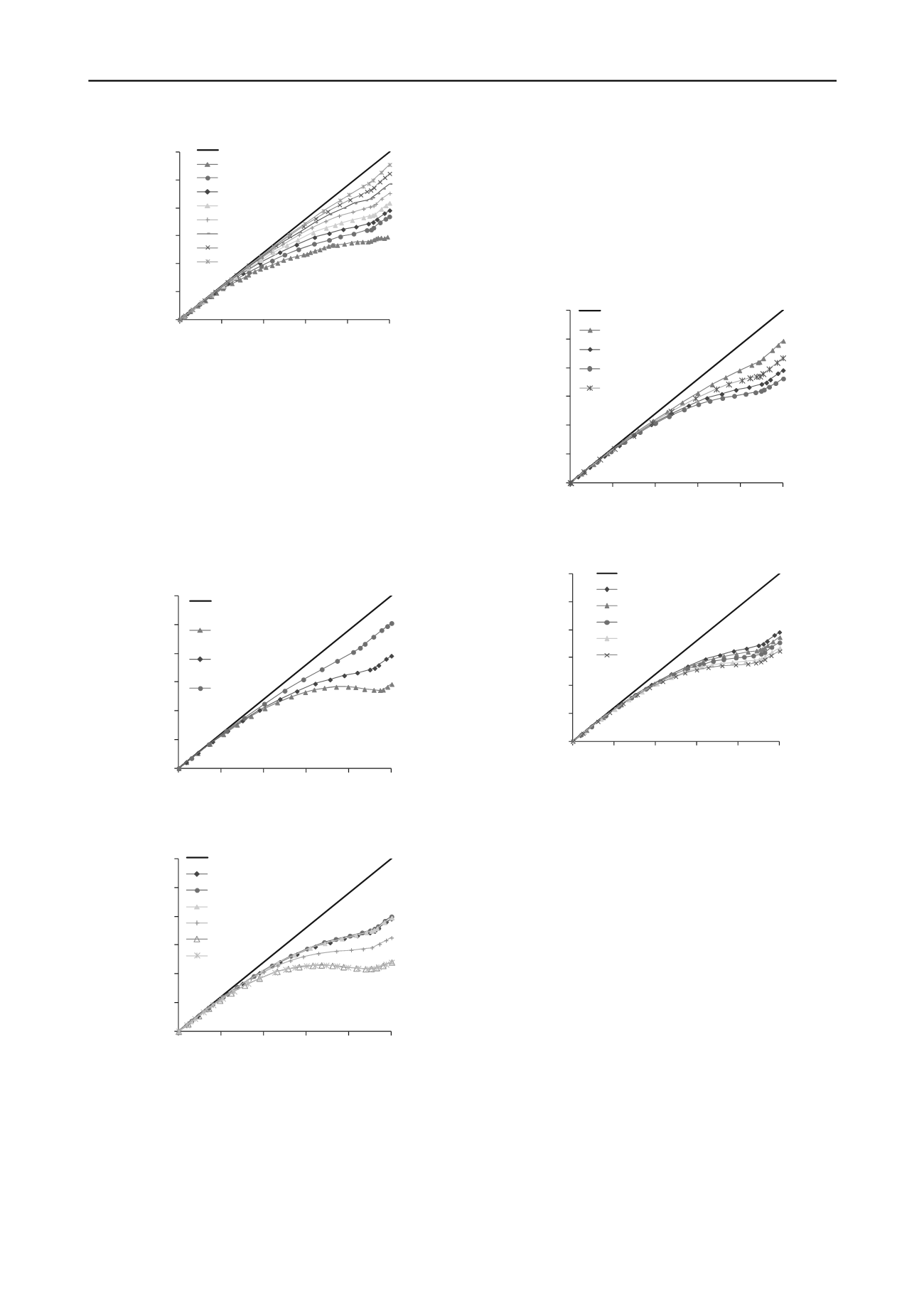

Figure 4. Vertical stress variation along the VCL of the trench for

different wall inclination angle

; other parameters are given in Table 1.

3.2

Effect of backfill properties

3.2.1

Cohesion

Figure 6 shows the vertical stress distributions obtained by

numerical simulations along the VCL for different values of the

backfill cohesion

c

'

b

. These results tend to indicate that the

stress magnitude may change significantly with the cohesion

within the interval between 1 kPa and 100 kPa. Below a value

of 1 kPa, the effect of cohesion can be considered negligible;

once the backfill cohesion value reaches 100 kPa, further

increase does not have any effect on the vertical stress

distribution (in the cases considered here).

0

30

60

90

120

150

180

0

2

4

6

8

1

v

(kPa)

h

(m)

0

overburden

1 m

2 m

4 m

Figure 5. Vertical stress distribution along the VCL for different width

at the base of the trench (

L

b

); details are given in Table 1.

0

30

60

90

120

150

180

0

2

4

6

8

1

v

(kPa)

h

(m)

0

overburden

0 kPa

0.1 kPa

1 kPa

10 kPa

100 kPa

1 000 kPa

Figure 6. Vertical stress distribution along the VCL for different backfill

cohesion

c

'

b

; details are given in Table 1.

3.2.2

Internal friction angle

Figure 7 presents the vertical stress distributions along the VCL

with the trench. These simulations results indicate that a

stronger backfill, with a higher friction angle

'

b

, induces more

stress transfer to the walls, due to arching effect, so the vertical

stresses are reduced.

It is worth noting here that these results are somewhat

different from those obtained for vertical and inclined backfilled

mine stopes, where the vertical stresses becomes almost

insensitive to

'

b

when the friction angle is greater than about

20° (e.g. Li and Aubertin 2009c; Singh et al. 2010).

3.2.3

Dilation angle

Figure 8 illustrates the vertical stress distribution along the VCL

in the trench, obtained for different backfill dilation angle

'

b

.

Results tend to indicate that the stress magnitude tends to

decrease slightly when the dilation angle increases from 0° to

30°.

0

30

60

90

120

150

180

0

2

4

6

8

1

v

(kPa)

h

(m)

0

overburden

10°

30°

40°

20°

Figure 7. Vertical stress distribution along the VCL for different backfill

friction angle

'

b

; details are given in Table 1.

0

30

60

90

120

150

180

0

2

4

6

8

1

v

(kPa)

h

(m)

0

overburden

0°

5°

10°

20°

30°

Figure 8. Vertical stress distribution along the VCL for different backfill

dilation angle

'

b

; details are given in Table 1.

3.2.4

Young's modulus

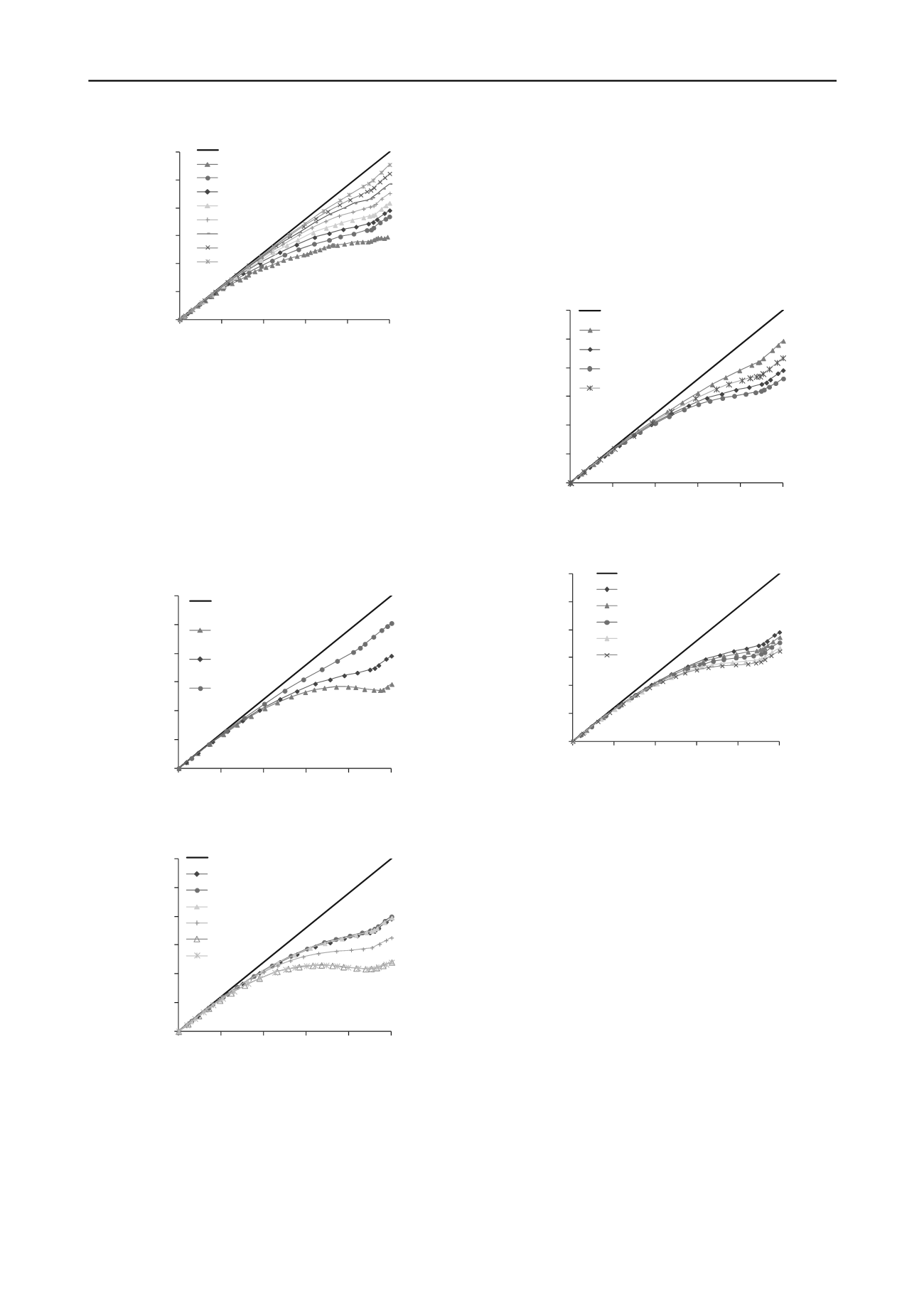

The influence of the backfill stiffness on the vertical stress

distribution along the VCL is presented in Figure 9. It is

observed that the vertical stress is almost constant when the

value of the Young's modulus of the backfill is smaller than

about 1/30

th

of that of the material forming the walls. Beyond

that value, the vertical stress can increase significantly with an

increase in backfill stiffness.

It is also seen that the vertical stress magnitude is always

below the linear overburden solution, even when the backfill is

stiffer than the wall, indicating that there is no negative arching

in these cases. This response is due to the fact that the

settlement of the soil adjacent to the trench takes place before

the fill is put in place. This differs from results predicted by

some conventional solutions.

3.2.5

Poisson's ratio

The influence of the Poisson's ratio of the backfill on the

vertical stress distribution along the VCL is presented in Figure

10. One sees that the influence of this parameter on the vertical

stress distribution is very limited. This observation is quite

different from that for inclined mine backfilled stope where the

vertical stress decreases significantly with an increase in

backfill Poisson's ratio (Li and Aubertin 2009c).