1226

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

lumped mass, which hits the impact foot after a free fall. The

initial velocity of the impact foot, which excites the

underground, was derived assuming an idealized elastic impact

between falling weight and the mass of the impact foot. The soil

medium was modeled as homogenous, isotropic, and rate-

independent elastoplastic halfspace based on Mohr-Coulomb

theory with isotropic hardening. The axially symmetric impact

foot made of steel rests on the surface of the halfspace. A

sliding interface between the foot and the soil was adopted, i.e.

only normal stresses are transferred between the foot and the

soil. The numerical model takes advantage of the rotational

symmetry of this subsystem, which is divided into a near-field

and a far-field. The near-field was discretized by means of

Finite Elements. Infinite Elements model the far-field in order

to avoid wave reflections at the boundary between the near- and

far-field, and to allow for energy propagation into the semi-

infinite halfspace. The model and its parameters are described in

more detail in Adam et al. (2010).

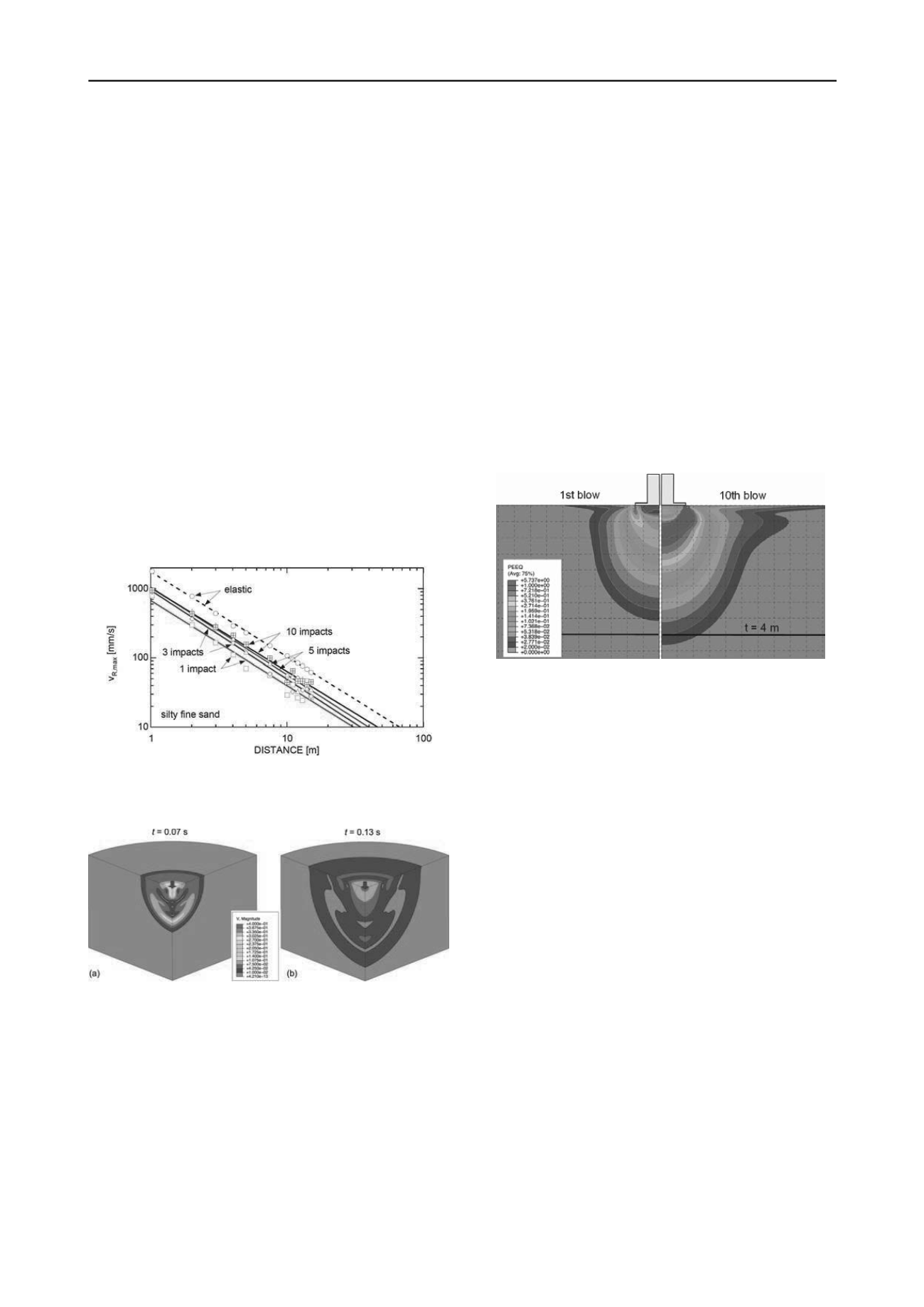

As an example, Figure 1 shows the peak velocity magnitude

v

R,max

with respect to the distance of the compaction point for

the subsoil condition silty fine sand after the first, third, fifth,

and tenth compaction pass. The outcomes of this figure prove

field observations that the pronounced increase of v

R,max

after

each compaction impact leads to a parallel shift of the

regression line, and thus, the arbitrary assumed limit value of

10 mm/s is shifted to a larger distance from the compaction

point.

Figure 1. Magnitude of maximum resultant surface velocity as function

of the distance from the impact foot after a specified number of

compaction impacts applied to an elastoplastic silty fine sand.

Figure 2. Distribution of the velocity magnitude at two specified

instants after the first compaction impact. Elastoplastic silty fine sand.

Figure 2 shows the propagation of the velocity magnitude at

two instants after the first impact is applied to the subsoil

condition silty fine sand. Spherical propagation of the waves

can be observed. Comparison of Figure 15(a) and Figure 15(b)

prove that geometric damping leads to a rapid decay of the

response amplitudes. According to Figure 15(b) the maximum

peak velocities develop at the soil surface, because Rayleigh

waves have the largest energy content. Furthermore, the faster

propagating P-waves can be distinguished from the slower S-

waves. According to the characteristics of P-waves in zones

between compression and dilatation the velocities are zero.

The effect of compaction and the compaction depth have

been investigated, because these properties serve to define the

application fields of the Impact Compactor with respect to soil

type and soil stratification. In numerical studies it was assumed

that the equivalent plastic strain is the characteristic parameter

for evaluation of the compaction depth. A threshold of 0.02

separates the compacted space from the non-compacted subsoil.

After each impact in the compaction zone the soil properties

were modified. Here, an isotropic hardening constitutive model

was used for an engineering-like approximation of soil

compaction.

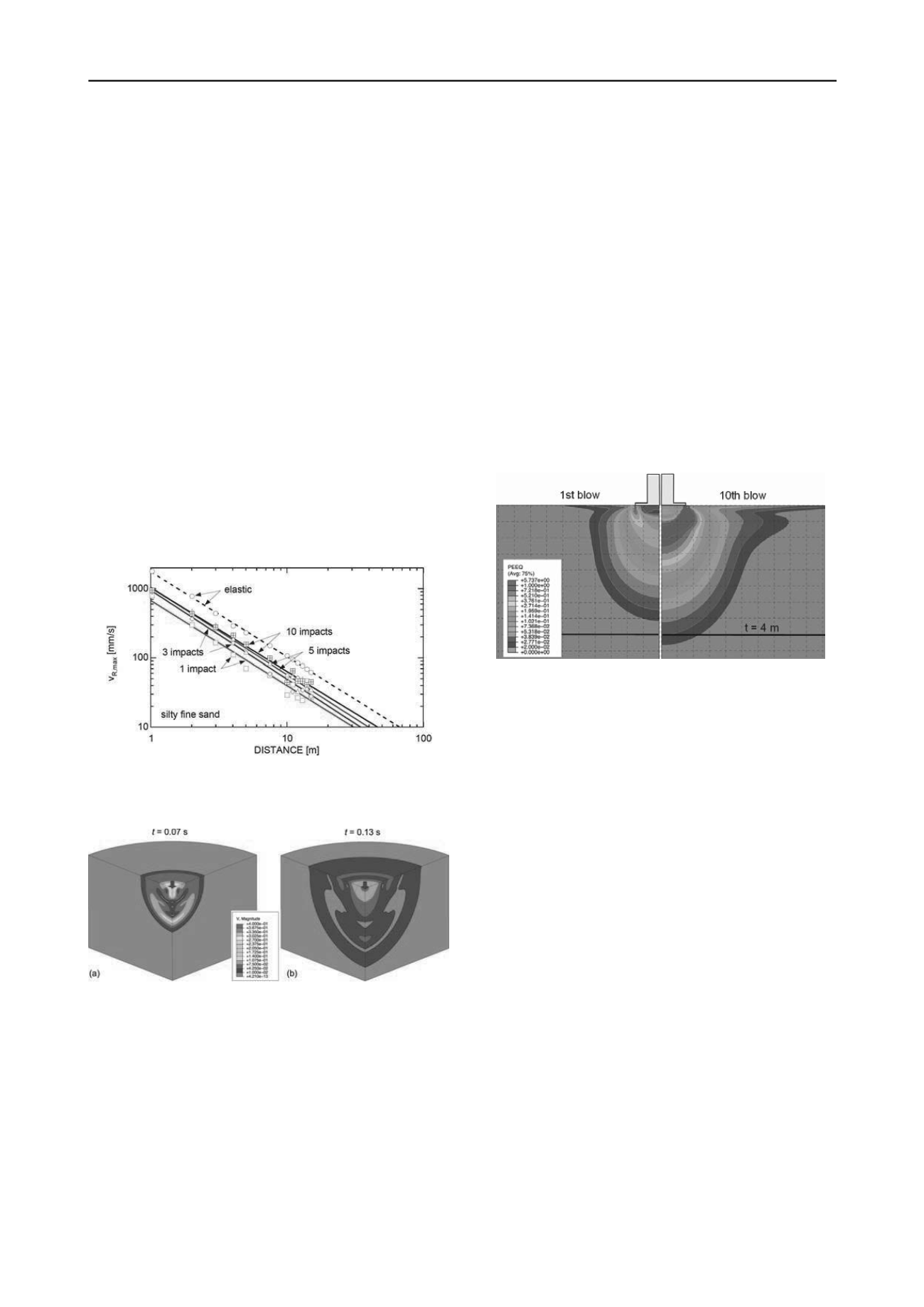

Figure 3 shows the expansion of the equivalent plastic

strains in a cross-section of homogeneous silty fine sand below

the impact point after the first and tenth compaction pass. The

colored area within the outer contour is considered as

compaction zone. The largest equivalent plastic strains occur

below the boundary of the compaction foot. The domains of

equal plastic strains, i.e. the domains of equal degree of

compaction, show the shape of a “stress bubble”. It can be seen

that in this example the soil is compacted laterally and

downwards with approximately the same magnitude. A thin

surface layer shows as well distinct equivalent plastic strains,

which are induced by Rayleigh waves. After the tenth impact

the compaction depth is about 4.3 m.

Figure 3. Spread of the equivalent plastic strain after the first (left) and

after tenth compaction impact (right). Elastoplastic silty fine sand.

2.2

Field experiments

Field tests on different soil conditions were performed to verify

theoretically derived outcomes. Moreover, they provide the

basis for the optimized and economic application of this

compaction method in the field.

Experimental results and field investigations confirm the

trends of the presented numerical outcomes (see chapter 3).

3 DEVELOPMENT AND APPLICATION

3.1

GPS-based recording system

The Impact Compactors are provided with a monitoring system.

The compaction monitor is a kit of parts, which can be coupled

to the compaction device in order to record the performance of

the hammer and the rate of ground improvement. The following

parameters are automatically recorded during the compaction

process and monitored from the cab with an on-board data

acquisition system (see Figure 4):

number of blows

final settlement at the last blow

total settlement (depth of the compaction crater)

compaction energy

average number of blows

In addition to these parameters a more novel device monitors

electronically the coordinates of the compaction points, date,

and time for each compaction point during the compaction

process, and all data are documented via GPS controlled data

acquisition (see Figure 4).

GPS-based data recording during the compaction process

and the online display in the operator’s cab facilitates

compaction control, an economic application of the compaction