1216

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

distribution on those GR strips. This is in agreement with the

observations in scaled-down model tests, numerical analysis and

field measurements.

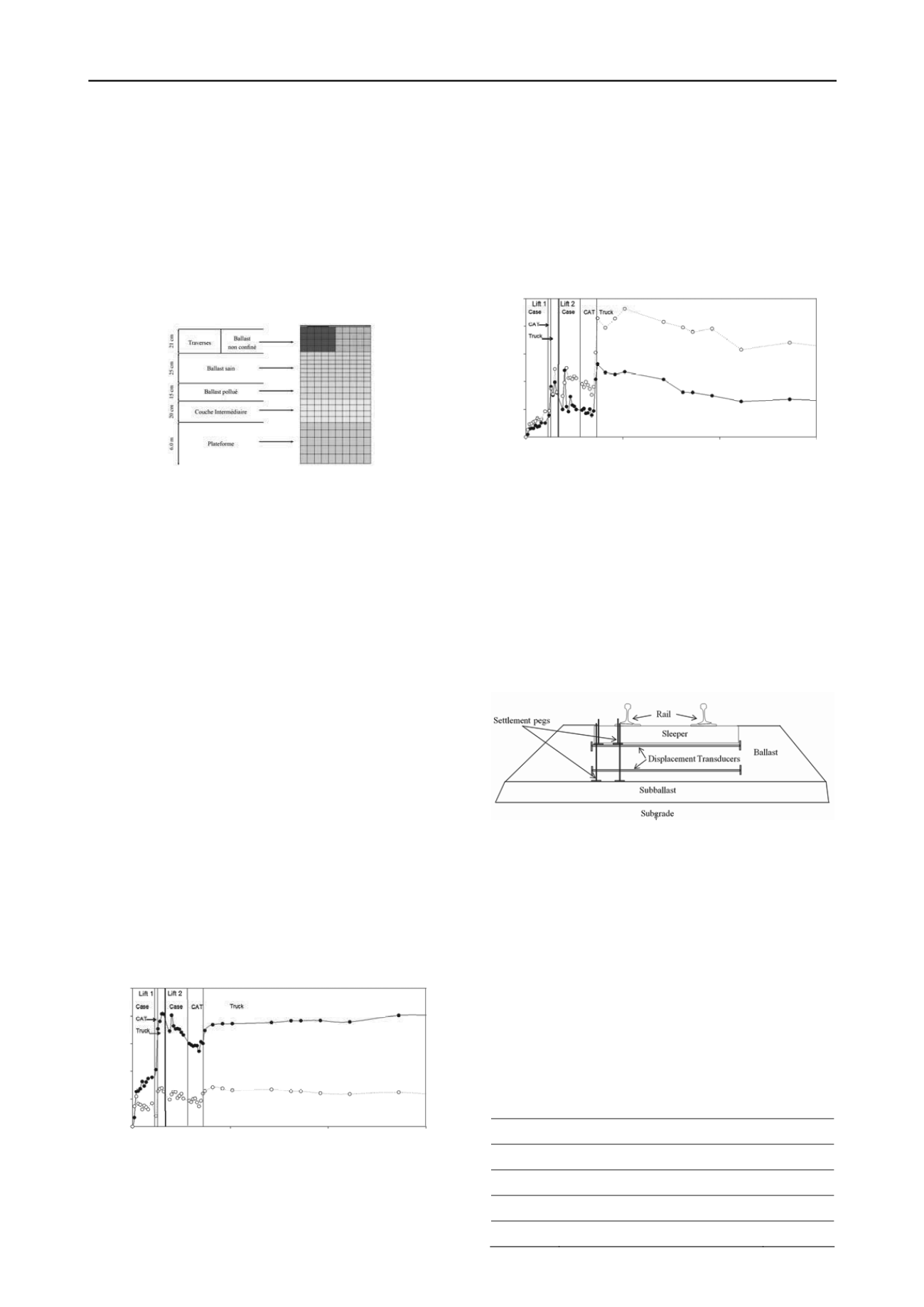

Fernandes et al. (2013) carried out a 2D finite element model

with a modified width (plane strain) where viscous boundaries

are implemented using a Kelvin-Voigt viscoelastic mechanical

model to reduce the wave reflexion on the boundaries. The

importance of initial state evolution of track materials on the

context of non-linear mechanical behaviour is discussed to

assure the correct combination of laboratory tests based on the

current track conditions, especially for ballast (Figure 7).

Figure 7. Finite element mesh discretisation of the railway structure

(Source: Fig 3, Fernandes et al. 2013).

5 APPLICATIONS OF GEOSYNTHETICS

In this section, 4 articles are described. The majority of articles

discuss general issues of geosynthetic reinforcement (Indraratna

et al. 2013, Wayne et al. 2013, Huckert et al. 2013), while other

article examines the stiffness of the soil-geosynthetic

intereaction under small displacement conditions (Zonberg et al.

2013).

Huckert et al. (2013) presented full-scale experiments to

study load transfers of geosynthetics-reinforced embankments

prone to sinkholes which are related to the complexity of

various mechanisms. Numerical model coupling both finite and

discrete element methods were performed and the results

compared with the experimental data. These simulations

provide a better understanding of load transfers towards the

edges of the cavity.

Wayne et al. (2013) presented results of two field studies and

model tests to evaluate performance of a geogrid-stabilized

unpaved aggregate base overlaying relatively weak and non-

uniform subgrade soils. Piezoelectric earth pressure cells (EPC)

were used to measure horizontal stress below and above the

geogrid location versus the passage of construction and truck

traffic. The variation of dynamic horizontal stresses within the

subgrade against the passage of truck traffic is presented in

Figure 8. This result indicated an enhanced fully confined zone

above the geogrid, resulting in an uniform vertical stress across

the subgrade that leads to reduced lateral stresses.

25

20

15

10

5

0

50 100 150

Unstabilised section

Stabilised section

Roller/Test cumulative pass count

Stress (kPa)

Figure 8. Horizontal stress within the subgrade layer after roller

compaction and test vehicle passes (Source: Fig 3, Wayne et al. 2013).

Figure 9 presents the horizontal stress in the base layer after

roller compaction and trafficking. It is clearly seen that the

geogrid confines the unbound aggregate leading to an increased

lateral stress within the aggregate. The results demonstrate that

the inclusion of geogrid at the interface of soft subgrade and

aggregate layers affects the development of the “locked-in”

horizontal stress upon loading. A higher horizontal stress within

the sttabilized aggregate layer gives a direct indication of the

lateral restraint mechanism. The result of increased aggregate

stresses leads to an increase in the resilient modulus of

aggregate adjacent to the geogrid.

25

20

15

10

5

0

50 100 150

Unstabilised section

Stabilised section

Roller/Test cumulative pass count

Stress (kPa)

Figure 9. Horizontal stress within the base layer after roller compaction

and test vehicle passes (Source: Fig 4, Wayne et al. 2013).

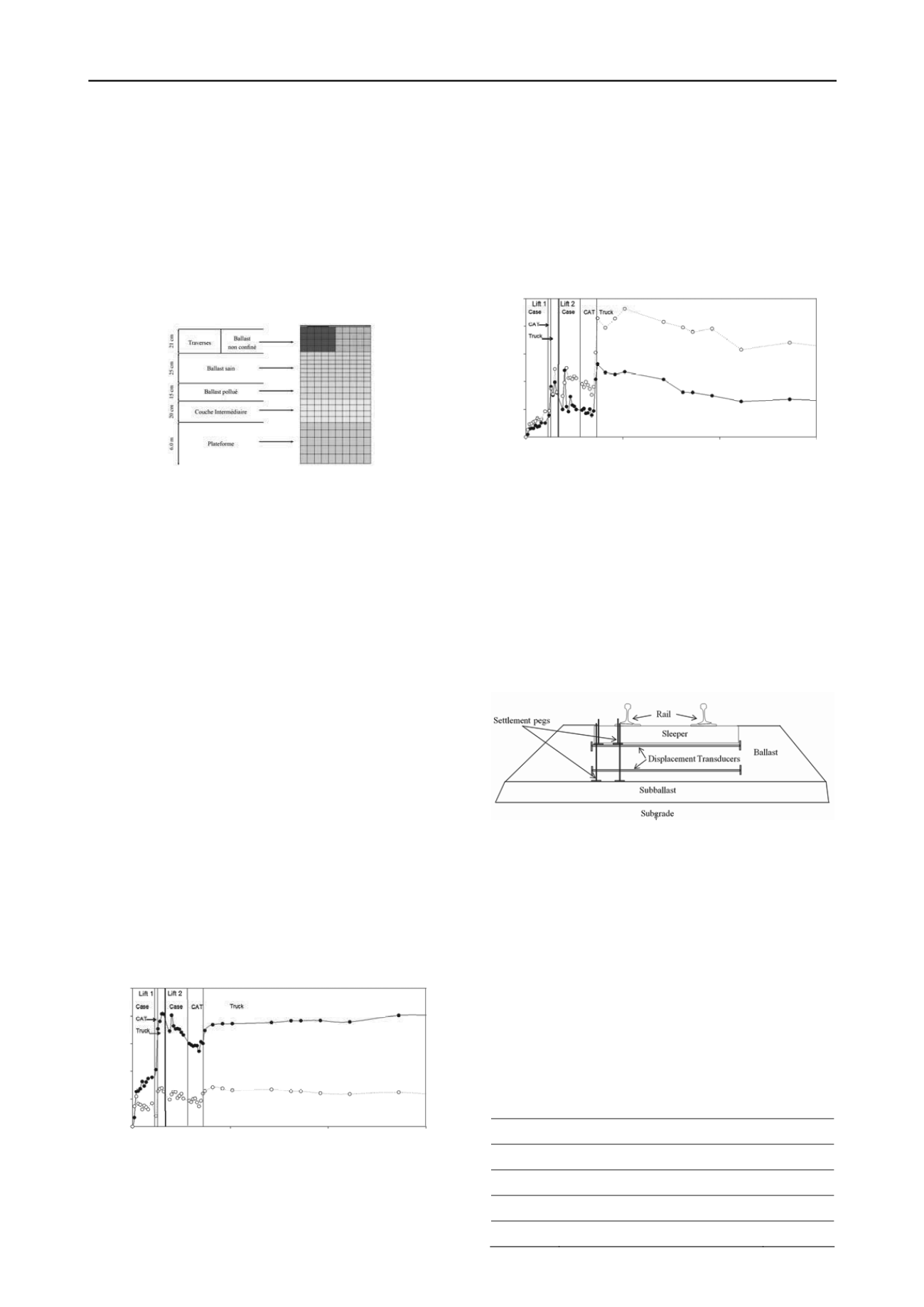

Indraratna et al. (2013) presented the results of full-scale

field tests conducted on rail track sections in the towns of Bulli

and Singleton (NSW, Australia) to measure track deformations

associated with cyclic stresses and impact loads. The vertical

and horizontal stresses induced in the track bed were recorded

by pressure cells. Vertical deformations of the track were

measured by settlement pegs, and lateral deformations were

measured by electronic displacement transducers. The

settlement pegs and displacement transducers were installed at

the

sleeper-ballast

and

ballast-subballast

interfaces,

respectively, as shown in Figure 10.

Figure 10. Installation of settlement pegs and displacement transducers

at Bulli site (Source: Fig 3, Indraratna et al. 2013).

The average lateral deformations of ballast at various

number of load cycles (N) are illustrated in Figure 11. It is

shown that the geocomposite decreased the lateral deformation

of fresh ballast by about 49% and that of recycled ballast by

11%. The capacity of the ballast to distribute loads was

improved by the placement of the geocomposite, which

substantially reduced settlement under high repeated loading.

Indraratna et al. also discuss the results of large scale drop-

weight impact testing equipment to evaluate the effect of using

shock mats in mitigating ballast breakage. The ballast breakage

was measured using the ballast breakage index (BBI) as shown

in Table 1. Installing layers of synthetic materials such geogrids

and rubber pads (shock mats) in rail tracks was found to

significantly reduce ballast degradation.

Table 1. Ballast breakage under impact loading (Source: Table 1,

Indraratna et al. 2013)

Base

Test Details

BBI

Stiff

Without shock mat

0.170

Stiff

Shock mat at top and bottom

0.091

Weak

Without shock mat

0.080

Weak

Shock mat at top and bottom

0.028