1214

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

aggregates (Fonseca et al. 2013) applied to transport

infrastructure are also presented and discussed.

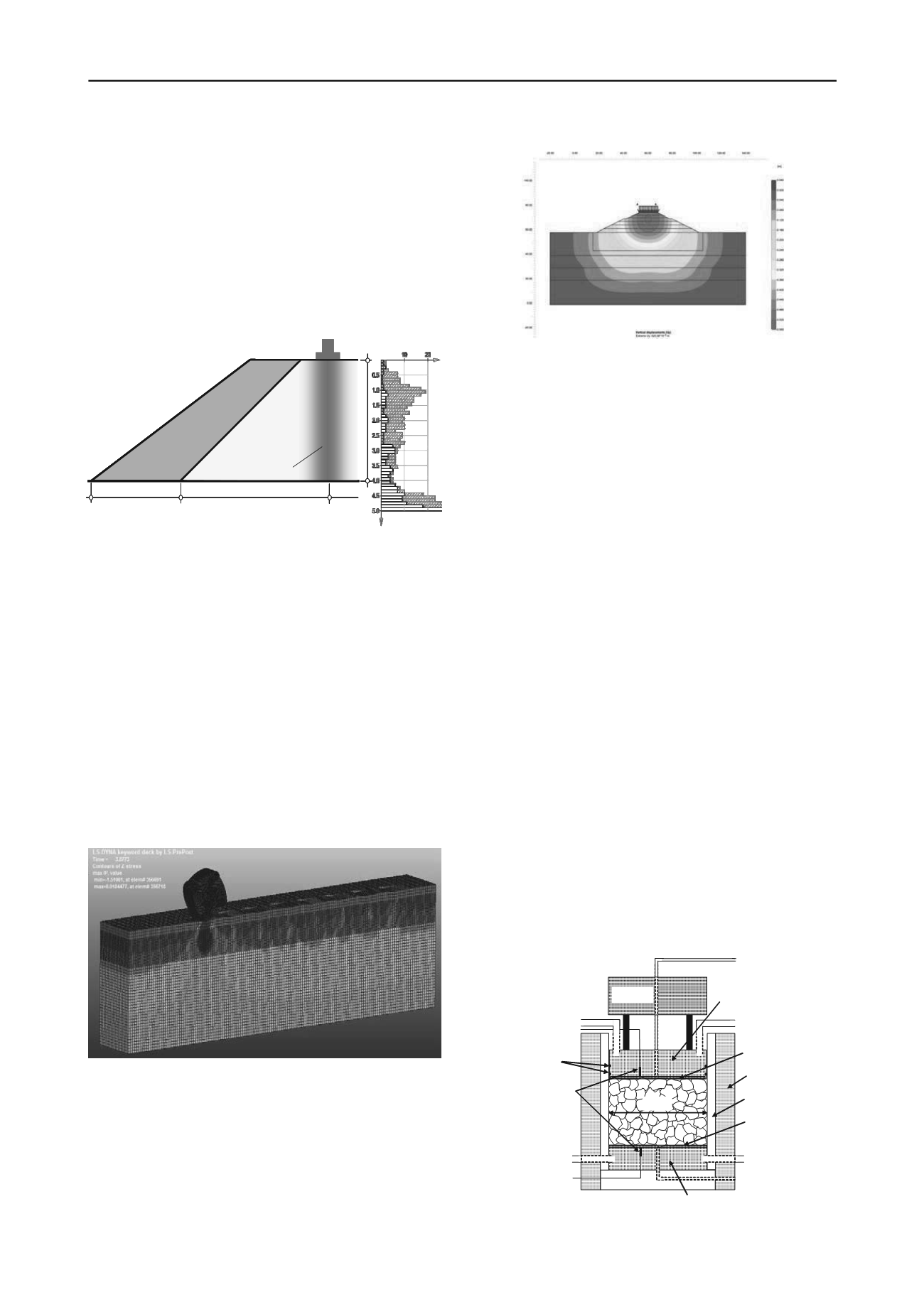

Adam et al. (2013) introduced a finite element modeling

framework for analyzing the performance and efficiency of an

impact compactor in relation to the surface velocity, weight of

impact compactor and number of passes. Field observations

indicate that the impact compactor is suitable for treating a wide

variety of loose soils and fills, but the effective treatment depth

is dictated by the grain size, typically ranging from 4.5m to 10m

depth. Experience of two case studies suggests that Dynamic

Probing Tests (Figure 1) are adequate for evaluating the

efficiency of compaction.

depth [m]

4.5 m

12.0 m

4.0 m

gravel

core

(loess / loam)

compacted zone

N

10

BEFORE RIC

AFTER

RIC

Figure 1. Test dike and correspondent dynamic probing test results.

(Source: Fig 8, Adam et al. 2013).

Kuo et al. (2013) have described the effectiveness of Rolling

Dynamic Compaction (RDC) by the combination of field

studies with numerical modeling (Figure 2). At the ground

surface, there are noticeable large deformations, and RDC

proves to be most effective between the depths of 0.8m and

3.0m. The preliminary parametric study showed that most

significant factors were soil cohesion, Poisson’s ratio and shear

modulus, as well as the width and mass of the RDC module.

An interesting study on the feasibility of a stiffness-based

specification for embankment soil compaction quality control is

discussed by Conde et al. (2013). An array of instruments are

adopted for compaction control, which measures soil stiffness

and then discussed on the basis of an earth dam construction.

Among the different equipment used, the DCP (dynamic cone

penetrometer) equipment showed greater promise as a

compaction control tool, partly attributed to the strong negative

correlation with water content values.

Figure 2. FEM model (Source: Fig 3, Kuo et al. 2013).

Kirstein et al. (2013) have described the application of a

combination of ground improvement techniques to stabilize a

recently placed brown coal landfill embankment for supporting

a new road. Owing to significant stability problems and the

small settlement tolerance of the structure (15 m deep),

“floating” stone columns were also installed. The design and the

associated settlements were significantly influenced by the

combination of different soil improvement techniques. The

settlement predictions were obtained using a finite element

model (Figure 3) and successfully verified against the results of

pressuremeter tests.

Figure 3. Representation of the predicted total settlements obtained with

Plaxis (Source Fig 10, Kirstein et al. 2013).

Fonseca et al. (2013) presented some intriguing results

obtained through laboratory studies performed on compacted

mixtures of cement and limestone aggregates. The results

indicated that the differences observed in dynamic and static

stiffness properties and shear strength parameters were directly

associated with the variation of porosity/cement ratio. As

expected, a higher stiffness and strength were obtained by

increasing the cement content and the degree of compaction.

While a hardening soil model could be employed to adequately

describe the observed stress-strain behaviour, the volumetric

predictions and the post-peak strain softening response could

not be reproduced satisfactorily.

3 LABORATORY TESTING

This section includes 6 articles. Two papers demonstrate the

results of California Bearing Ratio (CBR) tests performed on

the subbase (Ishikawa et al. 2013) and the subgrade (Moayed et

al. 2013). Some studies focus on cyclic loading tests on ballast

(Kumara and Hayano 2013) and subgrade (Mohanty and

Chandra 2013), while the others investigate the overall

performance of railway track (Calon et al. 2013, Hayano et al.

2013).

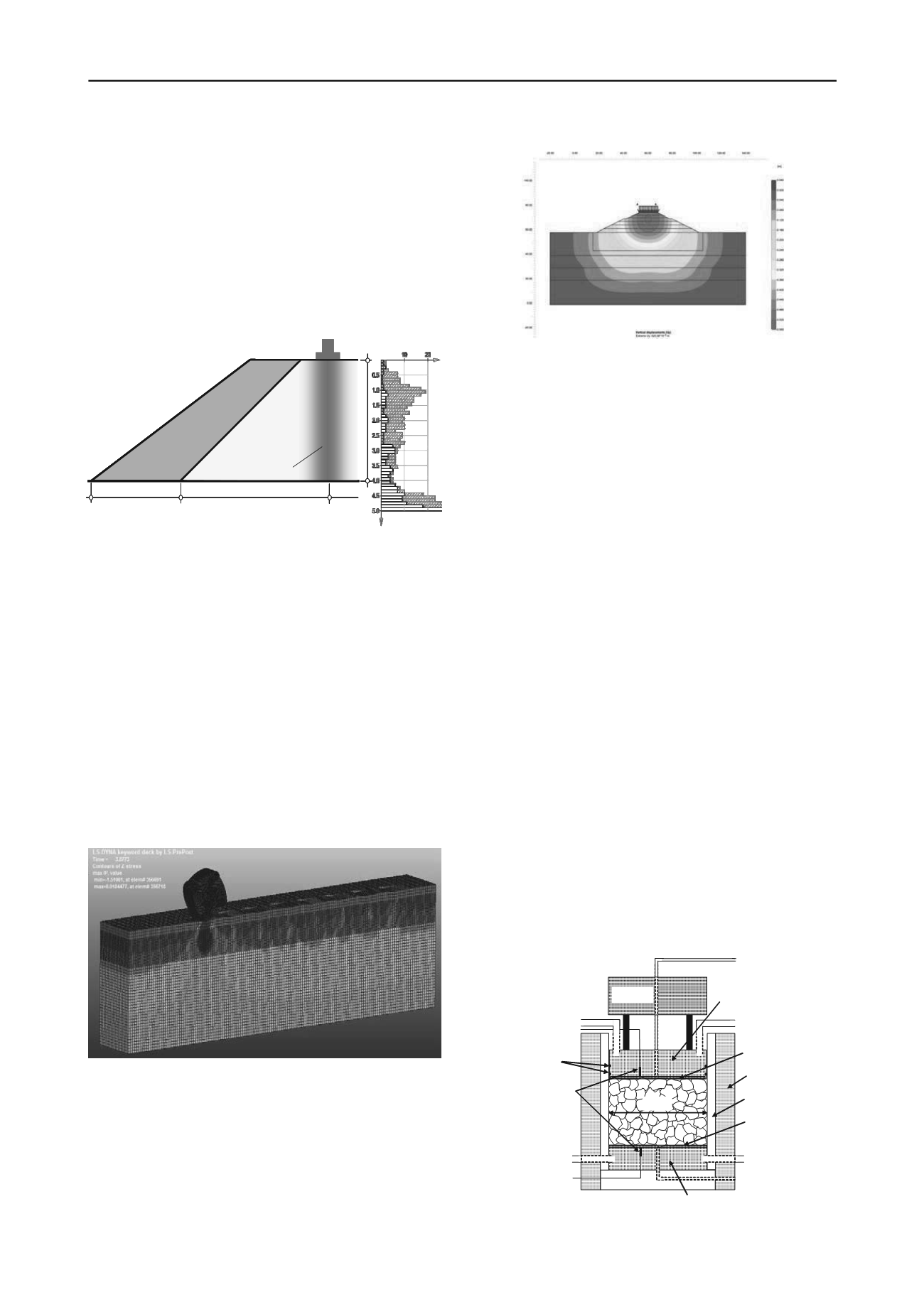

Ishikawa et al. (2013) examined the effects of freeze-thaw

and water content on the deformation-strength properties of

granular base materials. Two types of tests are conducted on

these materials under various water contents. One test is based

on the newly developed CBR equipment (Figure 4), and the

other using medium-size triaxial apparatus. The freeze-thaw of

granular base showed a strong influence on the fatigue life of

pavement structures. When number of freeze-thaw process

cycles increased, CBR values decreased regardless of the water

content. Resilient modulus showed a decreasing tendency with

the increasing water content.

150

Surcha

rge

Water supply

/ drainage

Coolant

circulating line

Insulation

Acrylic cell

Base cooling plate

Temperature

sensor (pt100)

Porous metal

with filter paper

O-ring

Water supply

/ drainage

Porous metal

with filter paper

Top cooling plate

Coolant

circulating line

Coolant

circulating line

Coolant

circulating line

Figure 4. Freeze-thawing CBR test apparatus. (Source: Fig 1, Ishikawa

et al. 2013).