1228

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

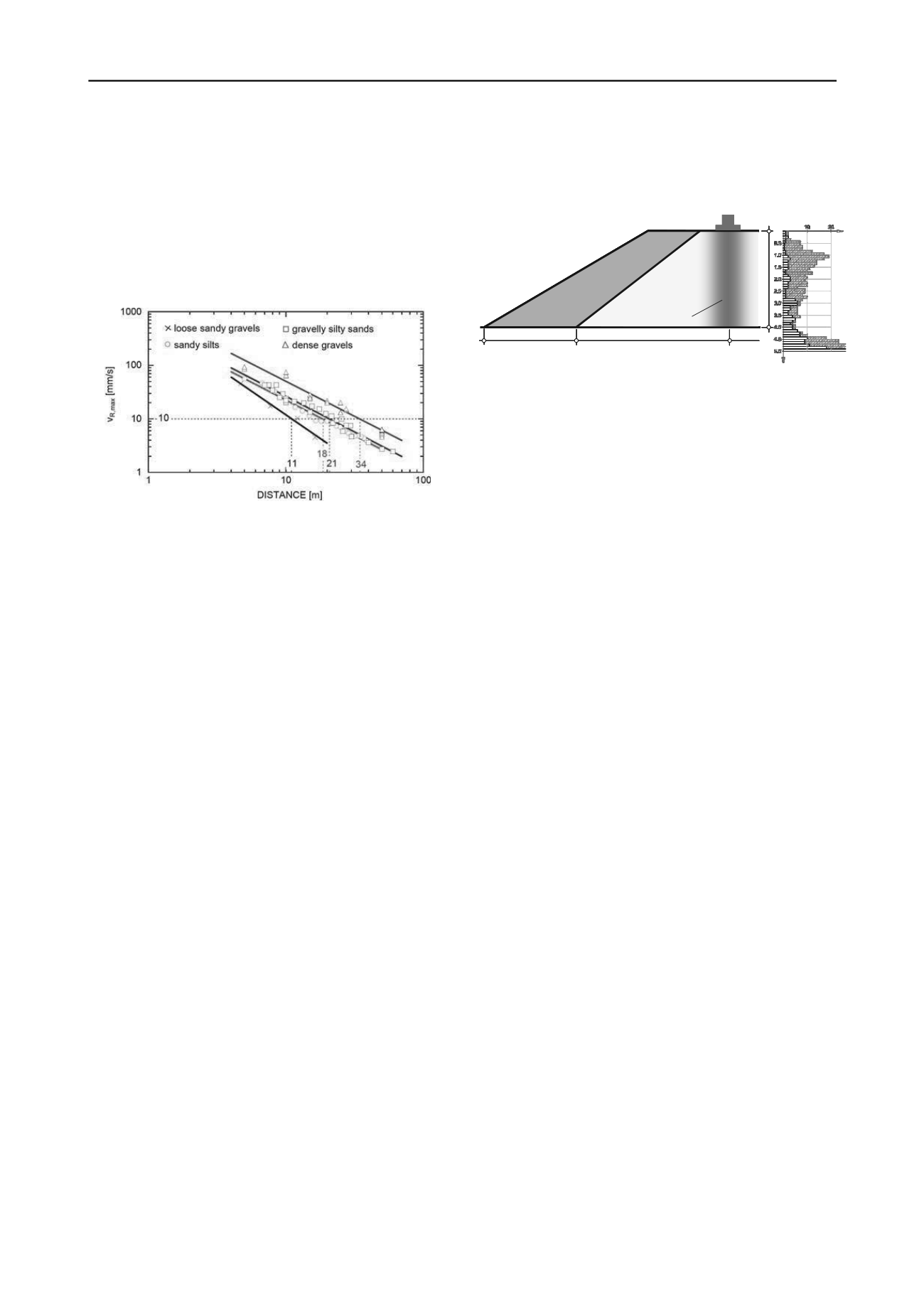

practically identical for dense gravels, sandy silts, and gravelly

silty sands. The results show that the peak velocity magnitude

falls below the value of max v

R,max

= 10 mm/s, i.e. the limit

value for buildings of the class no. III according to the Austrian

Standard ÖN S 9020, at a distance of 11 to 34 m from the

impact foot, depending on the subsoil condition and soil type.

Based of hitherto experience the required minimum distance to

buildings of class no. III is about 20 m. In comparison

compaction of heavy tamping techniques induces resulting

velocities of more than 10 mm/s at a distance of 30 m.

Figure 7. Magnitude of maximum resulting velocity as function of the

distance from the impact foot. Measured values for different soil types.

4 SELECTED CASE HISTORIES

4.1

Ground improvement for embankments and foundations

In the last five years the standard application for the Impact

Compactor was the ground improvement for embankments and

foundations. Typical fields of application are:

improvement of the ground in the embankment base

compaction to increase the bearing capacity of foundations

and/or reduce the liquefaction potential of soils

improvement of the ground bedding conditions for slabs

combined application with other compaction methods such

as heavy tamping or deep vibro-compaction when large

compaction depth is required, or lime stabilization of soft

cohesive soils on top of the ground (Adam et al. 2010)

4.2

Rehabilitation of flood protection dikes

The efficiency of the Impact Compactor to improve existing

flood protection dikes alternatively to e.g. the mixed-in-place

method (MIP) was investigated by compaction of the core of a

test dike (Adam et al. 2010).

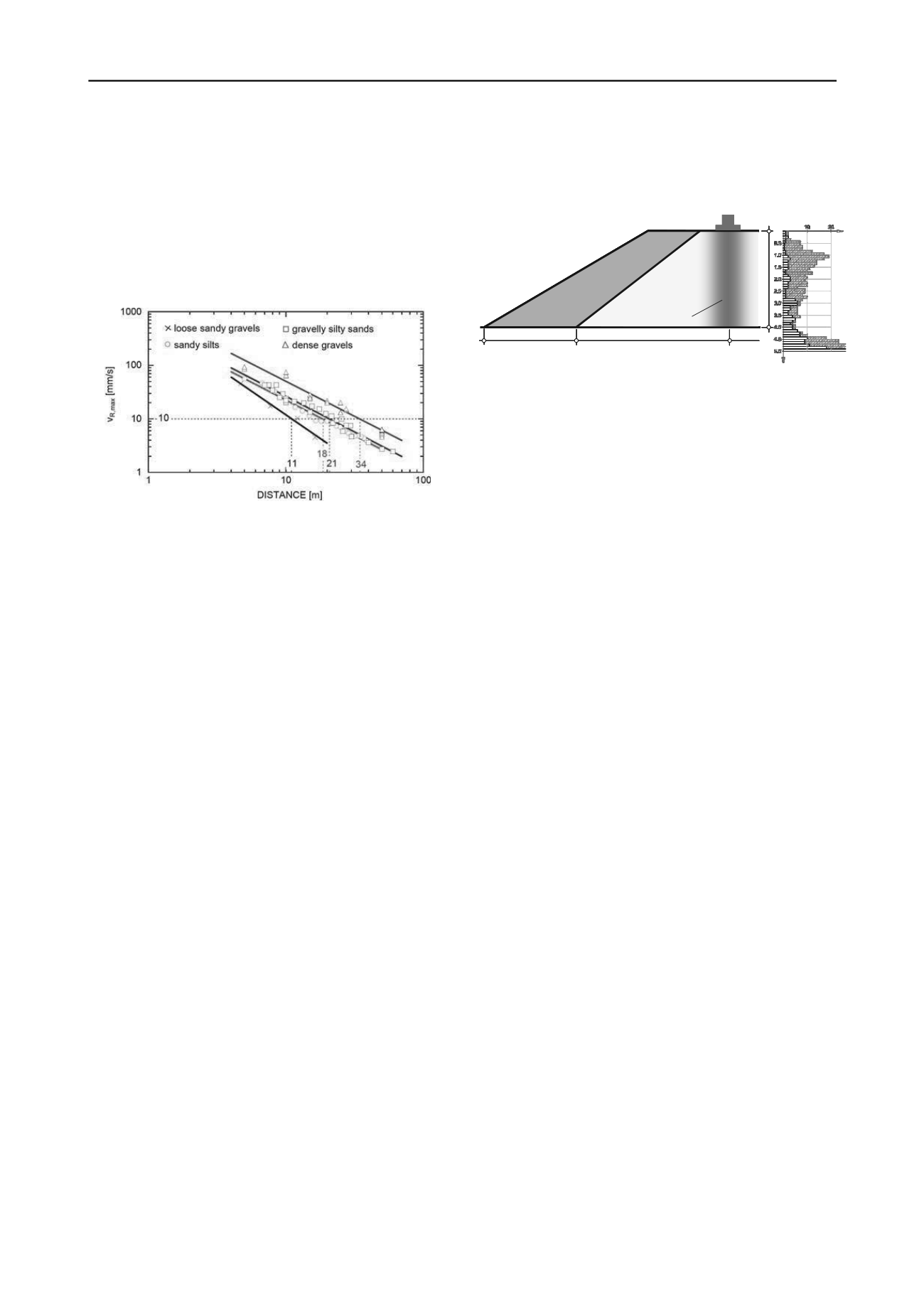

The test dike was constructed on a gravelly ground, which is

covered with a loess layer of about 0.75 m thickness. The core

of the embankment was built layer-wise with a layer thickness

of about 1 m. Each layer was only “pre-compacted” with a

vibratory roller in order to simulate the weak compactness of

existing old flood protection dikes. For one half of the

embankment core sandy silt (loess) was used as filling material,

for the other half silt (loam). The shoulders and slopes were

constructed with sandy gravel (see Figure 8).

Optimization and control of compaction was realized by the

following tasks and criteria:

meeting the stop code criteria

GPS-based documentation of the compaction parameters

performance of dynamic probing heavy (DPH) before and

after compaction

performance of dynamic load plate test using the LFWD

before and after compaction

in-situ permeability tests

In the following selected results of dynamic probing tests are

presented exemplary, which were carried out to determine the

compaction depth. Figure 8 (right) illustrates the number of

blows N

10

over depth determined with dynamic probing heavy

in the test section consisting of loess. It is obvious that the depth

effect of the Impact Compactor is about 4.5 m. Figure 8 reveals

that the upper zone of the gravelly ground beneath the

embankment was compacted as well.

depth [m]

4.5 m

12.0 m

4.0 m

gravel

core

(loess / loam)

compacted zone

N

10

BEFORE RIC

AFTER

RIC

Figure 8. Section of the test dike (left) and Dynamic Probing Heavy in

the loess (right).

5 CONCLUSION

In Central Europe the Impact Compactor was introduced in

2007. The novel compaction equipment provides a technically

sound and economic method of improving the capacity of a

wide variety of loose soils (silts, sands, gravels, cobbles,

boulders) and fills. The effective treatment depth in soils is

dictated by grain sizes and is typically in the range of 4.5 m (silt

and sand) up to 7.5 m (10 m) depth (sand and gravel). Due to

the numerous benefits, e.g. monitoring of the compaction

process through a GPS-based recording system (on-board

computer), reliability and safety in operation, quality assurance,

versatility and working speed, the Impact Compactor is now a

well established dynamic compaction method throughout

Europe.

6 ACKNOWLEDGEMENTS

The Austrian Research Promotion Agency (FFG) has funded

this research project. This support is gratefully acknowledged.

7 REFERENCES (TNR 8)

Adam D., and Paulmichl I. 2007.

Impact compactor – an innovative

dynamic compaction device for soil improvement.

In: Proc. 8th

International Geotechnical Conference (June 4-5, 2007, Slovak

University of Technology, Bratislava, Slovakia), pp. 183-192.

Falkner F.-J., Adam C., Paulmichl I., Adam D., and Fürpass J. 2010.

Rapid impact compaction for middle-deep improvement of the

ground – numerical and experimental investigation.

In: 14th

Danube-European Conference on Geotechnical Engineering "From

Research to Design in European Practice", June 2-4, 2010,

Bratislava, Slovakia, CD-ROM paper, 10 pp.

Adam C., Falkner F.-J., Adam D., Paulmichl I., and Fürpass J. 2010.

Dynamische Bodenverdichtung mit dem Impulsverdichter (Dynamic

soil compaction by the Rapid Impact Compactor

, in German

).

Project No. 815441/13026 – SCK/KUG, Final report for the

Austrian Research Promotion Agency (FFG), 184 pp.

Adam C., Adam D., Falkner F.-J., and Paulmichl I. 2011.

Vibration

emission induced by Rapid Impact Compaction.

In: Proc. of the 8

th

International Conference on Structural Dynamics, EURODYN

2011, p. 914-921, 4 – 6 July 2011, Leuven, Belgium.

Fürpass J., and Bißmann, M. 2012.

5 Jahre Impuls-Verdichtung in

Europa. Rückblick auf ein Erfolgsmodell

(in German). In: 2.

Symposium Baugrundverbesserung in der Geotechnik, p. 149-163,

13 – 14 September 2012, Vienna, Austria.