1238

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

loads. Given the non-linear resilient characteristics of soils and

granular materials, it is important to use an appropriate stress

level when testing. If a hand-held Lightweight Deflectometer

(LWD) is used, the stress level will be lower and the zone of

influence smaller so a correlation exercise with the FWD has to

be carried out and this is site specific.

In order to assess resistance to rutting, a standard truck of

known axle load is operated on the completed foundation to

deliver the equivalent of 1000 standard 80kN axle loads. The

accumulated permanent deformation in the wheel tracks is

measured and assessed against allowable values which depend

on the layer thicknesses and material types.

During the design phase, it is convenient to use a simple

laboratory test to determine the resilient characteristics of

potential materials for use in the foundation. This provides input

data to the design analysis which can generate a combination of

layers of particular thicknesses with an overall effective surface

modulus to satisfy the design specification for one of the

foundation classes. A site trial involving one or more potential

solutions can then provide confirmation that the target surface

modulus has been achieved.

3 LABORATORY TESTING

3.1

Background

The testing philosophy is an extension of that adopted for

asphalt, which resulted in the Nottingham Asphalt Tester

(NAT), (Cooper and Brown, 1989) being developed as a simple

low cost facility for use in engineering practice. It consisted of a

pneumatically driven loading frame into which different test

modules could be placed in order to measure various

mechanical properties of an asphalt test specimen under

repeated loading, including stiffness modulus, resistance to

fatigue cracking and to permanent strain accumulation.

Using similar principles to those applied by Semmelink and

de Beer (1995) for their K-Mould, Edwards et al (2005)

developed a test module for unbound and weakly stabilized

materials (known as a ‘Springbox’) that fitted into the NAT test

frame. This involved a 170mm cubical specimen contained in a

box with one opposite pair of vertical faces rigid and the other

pair spring loaded to simulate the confining situation insitu for

an element of compacted aggregate. Vertical loading was

applied through a square loading platen at a frequency of 1Hz

by the pneumatic actuator and measurements of both resilient

and plastic deformations were taken under repeated loading.

3.2

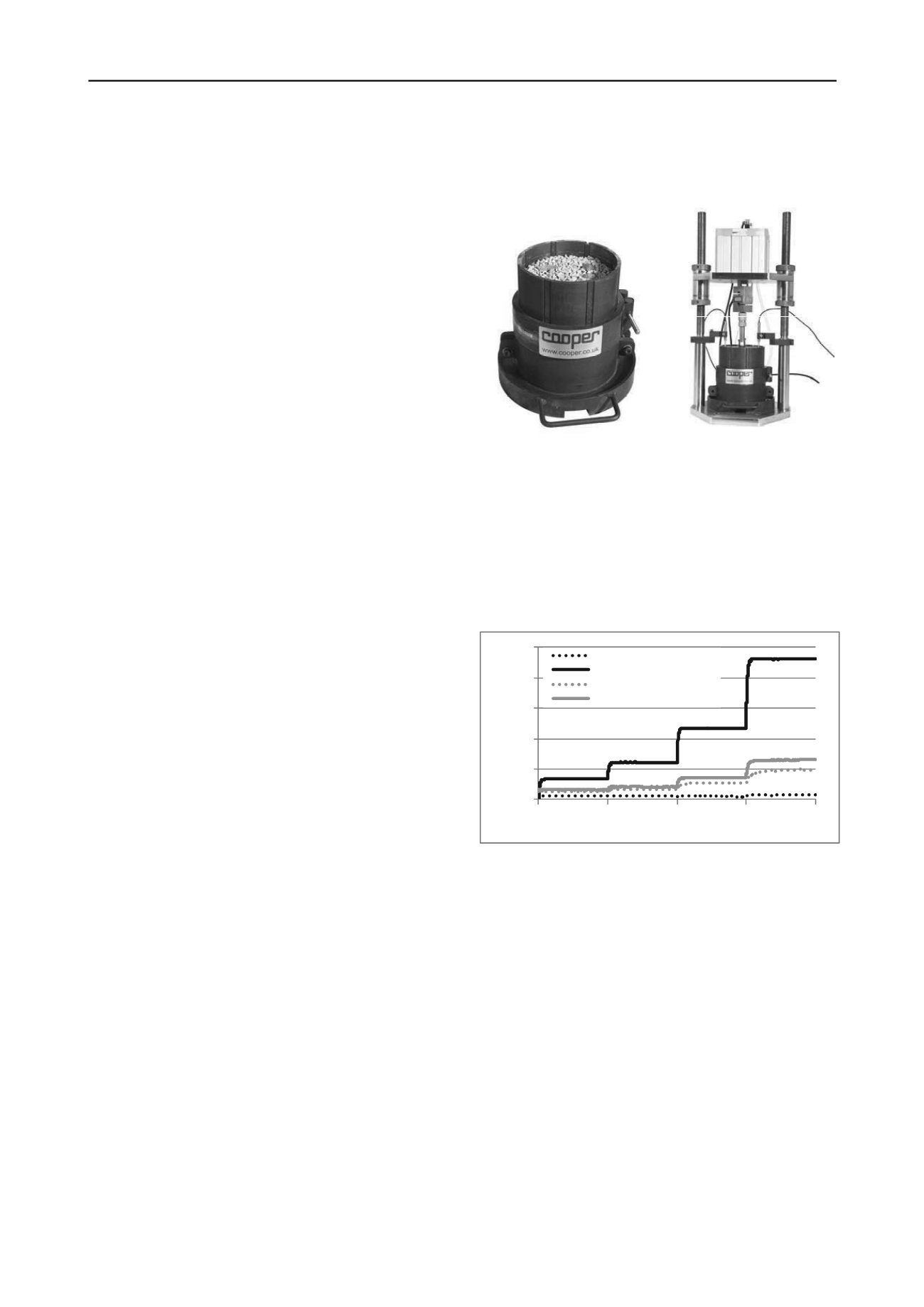

The Precision Unbound Materials Analyzer (PUMA)

One of the perceived disadvantages of the Springbox is its

square cross-section, raising the possibility of non-uniform

compaction and non-homogeneous stress conditions. The

PUMA, shown in Figure 1, therefore, adopts a similar 150mm

diameter circular shape to that of the K-Mould but with a

slightly increased height of 150mm. Like the K-Mould it is

confined within eight curved wall segments. The specimen,

which is compacted using standard equipment (e.g. a vibrating

hammer) at a desired water content, is then loaded on its top

surface by a circular platen. Side walls are confined within a

rubber-lined steel band, the rubber providing the possibility of

wall movement under load, simulating the elasticity of

surrounding material in-situ. Under repeated vertical loading a

residual horizontal stress will accumulate, typically between

10kPa and 50kPa, again simulating the in-situ condition.

Measurements are taken as follows: a) vertical load from a

load cell; b) vertical displacement of the top surface from

LVDTs, optionally inserted through holes in the top platen; c)

horizontal strain in the steel confining band from a strain gauge.

This last measure is directly proportional to the stress in the

steel band and, therefore, to the horizontal stress in the

specimen. It is also proportional to the horizontal strain in the

specimen, via the known compressibility of the rubber lining.

Thus, while only vertical stress is controlled, vertical and

horizontal stress and strain are all monitored during the test.

Figure 1. The Precision Unbound Material Analyzer (PUMA)

3.3

Analysis of Test Conditions

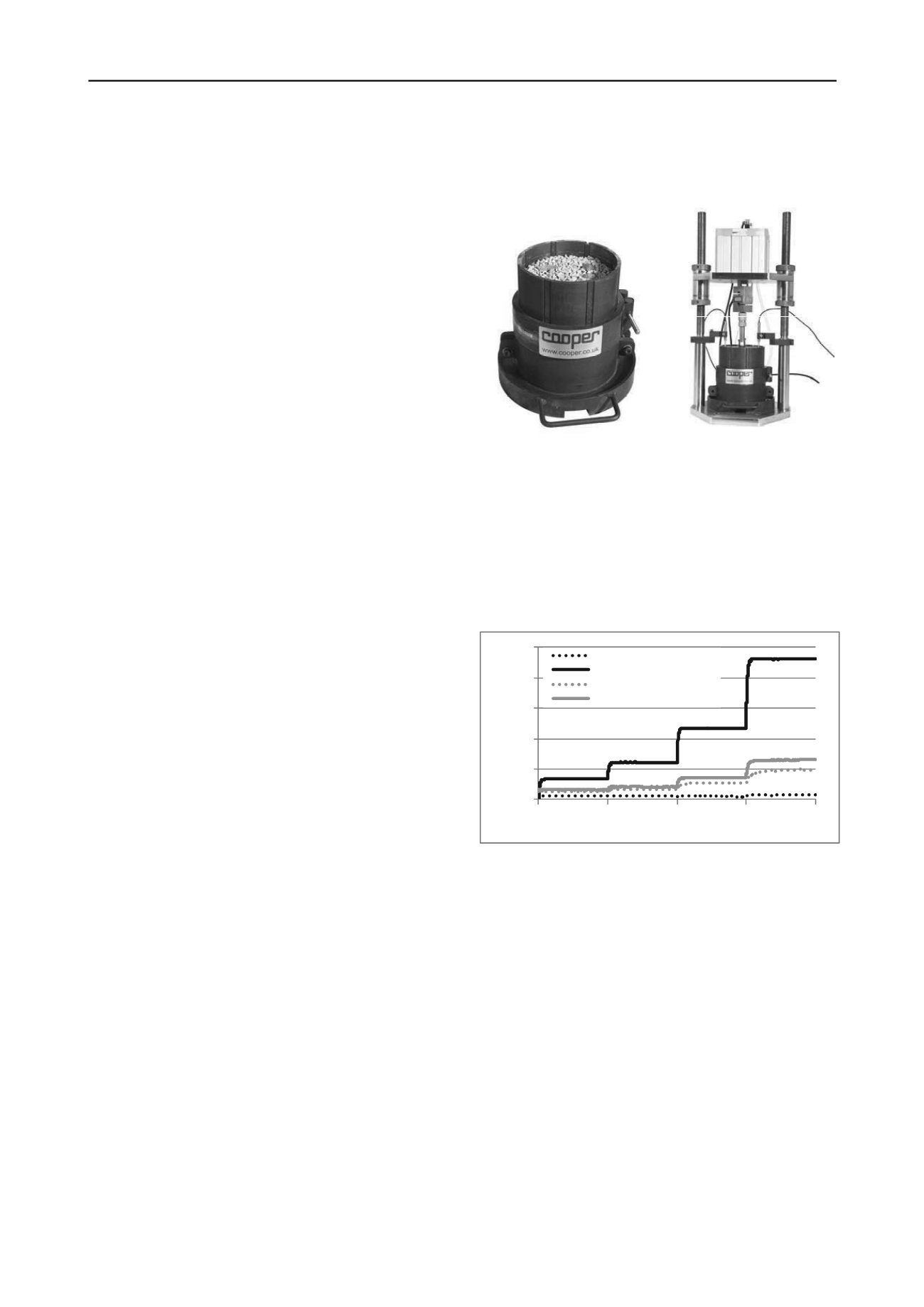

In order to maximize the information that could be derived from

a single test during the development of the equipment,

specimens were loaded in four stages each involving 1000 load

applications. Vertical stress levels up to about 250kPa were

used, above an initial preload of typically 5kPa. Since

horizontal stress is not controlled, values varied according to the

material tested. Figure 2 illustrates stresses measured during a

typical test on a natural gravel.

0

50

100

150

200

250

0

1000

2000

3000

4000

Stress during test (kPa)

Number of load applications

Vertical stress ‐ min

Vertical stress ‐ max

Horizontal stress ‐ min

Horizontal stress ‐ max

Figure 2. Stresses measured during a typical PUMA test

As a first approximation, friction between the walls and the

specimen could be neglected and the measured stresses and

strains converted directly into a stiffness modulus and Poisson’s

ratio, treating the material as a linear elastic solid. This is the

method specified in EN 13286-7 (CEN, 2004) in relation to

interpretation of triaxial data. Nevertheless, it is self-evidently

inaccurate to ignore friction between the walls and the specimen

as well as friction against the upper and lower platens. Direct

measurements taken during development of the PUMA

equipment suggested that a coefficient of friction of around 0.5

could be expected. The effect of this would be to transfer

vertical load to the walls, reducing the stress at the lower platen.

Similarly, platen friction would mean that not all the internal

horizontal stress within the specimen would reach the walls and

be measured. An approach to take account of this has been

outlined by Thom et al (2012) who developed the following

correction equations.

v(corrected)

=

v(measured)

– 0.5μh (

hmax

+

hmin

)/r

(1)

h(corrected)

=

h(measured)

+ 2μr (

vmax

+

vmin

)/15h

(2)