1239

Technical Committee 202 /

Comité technique 202

where:

vmax

= vertical stress at full load

vmin

= vertical stress on unloading (slightly > 0)

hmax

= horizontal stress at full load

hmax

= horizontal stress on unloading

v

=

vmax

–

vmin

h

=

hmax

–

hmin

μ

= coefficient of friction (0.5 assumed)

h

= specimen height (approximately 150mm)

r

= specimen radius (75mm)

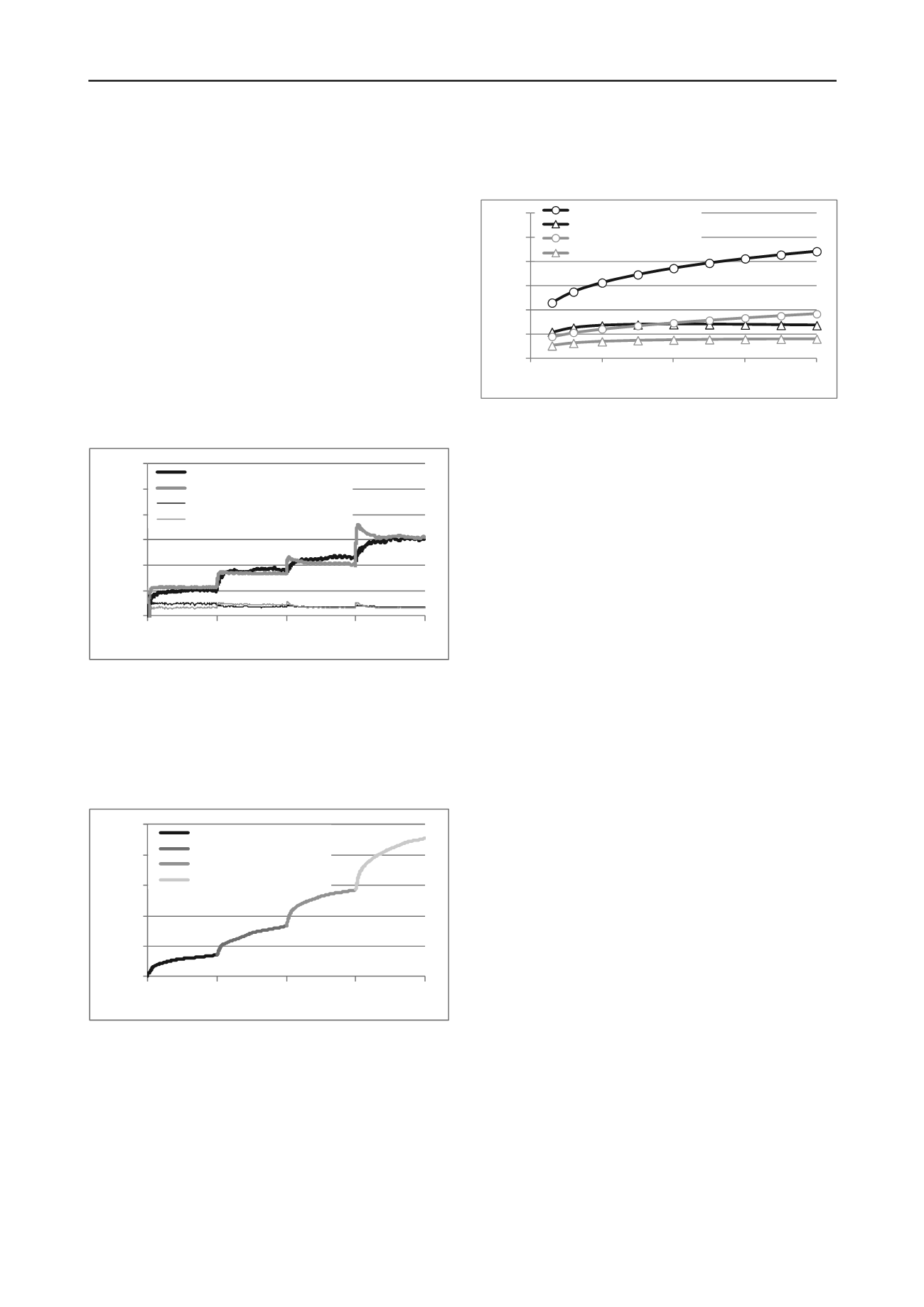

With these corrected stresses, the stiffness modulus and

Poisson’s ratio can be calculated with greater accuracy. Figure 3

shows a typical set of results from a PUMA test on a gravel

aggregate. On the figure, these are compared with a set of

predictions based on equations for the resilient non-linear stress-

strain behaviour of a gravel aggregate contained in Thom

(1988), providing a degree of added confidence that the

measurements and their interpretation are approximately

correct.

0

50

100

150

200

250

300

0

1000

2000

3000

4000

Modulus (MPa) / v x 100

Number of load applications

Siffness modulus ‐ test

Stiffness modulus ‐ prediction

Poisson's ratio (v) ‐ test

Poisson's ratio (v) ‐ prediction

Figure 3. Stiffness modulus and Poisson’s ratio – corrected for friction

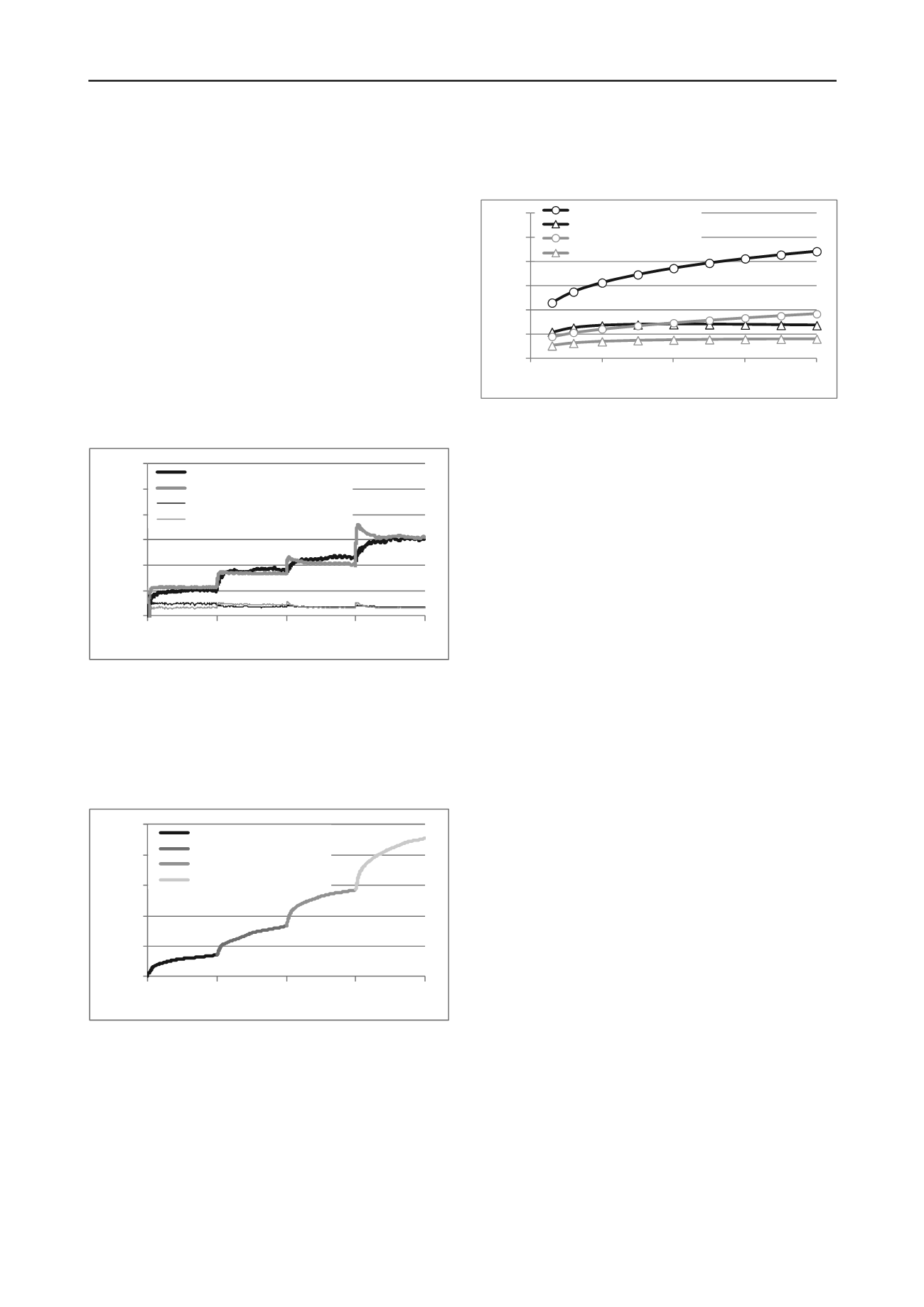

Figure 4 shows some typical results for the accumulation of

permanent strain under the four stages of repeated loading. Use

of data of this type is not presently catered for in the Highways

Agency’s design method but it can be useful at the material

selection stage for use on a comparative basis.

0

0.5

1

1.5

2

2.5

0

1000

2000

3000

4000

Vertical strain (%)

Number of load applications

Vertical stress: 5‐23kPa

Vertical stress: 5‐43kPa

Vertical stress: 5‐85kPa

Vertical stress: 7‐175kPa

Figure 4. Accumulation of permanent strain in a typical PUMA test

4 USE OF DATA

4.1

Selection of Appropriate Stress Level

A key requirement for a realistic stiffness modulus test is that

the stress conditions should be representative of those in the

pavement. For a completed pavement, an estimate of such

conditions can be derived from multi-layer linear elastic

analysis and this was carried out for two cases, one with 140mm

of asphalt (Case 1) and the other with 240mm (Case 2),

assuming a temperature of around 20

C. At mid-depth in a

200mm base layer below the asphalt, the computed stresses due

to a 100kN axle (50kN wheel) load were found to be as shown

in Figure 5.

0

50

100

150

200

250

300

0

500

1000

1500

2000

Compressive stress (kPa)

Base StiffnessModulus (MPa)

Case 1: vertical stress

Case 1: horizontal stress

Case 2: vertical stress

Case 2: horizontal stress

Figure 5. Predicted traffic induced stresses at mid-depth in the base

layer

Although the stresses in Figure 5 only represent a limited

range of examples, they suggest the sort of stress levels that

should be applied to achieve a realistic stiffness modulus for

pavement design. For example, using the data in Figures 2 and 5

and taking the case of a 300MPa base layer, the stress

conditions would be similar to Stage 3 of the test routine in the

case of a 140mm asphalt pavement and Stage 4 with 240mm of

asphalt.

It is also necessary to consider the case of insitu testing using

an LWD, which typically applies a vertical stress of about

100kPa, and for which it is difficult to predict the appropriate

horizontal stress due to the non-linear nature of granular

materials. Nevertheless, adopting an earth pressure coefficient

approach the situation is akin to an active rather than passive

state, in which case the ratio of vertical to horizontal stress is

likely to be of the order of 4 to 5. This gives a likely horizontal

stress of 20kPa to 25kPa near to the surface under an LWD

load. Since it is known that the horizontal stress state has a

controlling influence on measured stiffness modulus, similar to

the effect of confining stress in a triaxial test, it is logical to

ensure that this is correctly simulated. This suggests that either

Stage 1 or 2 of the proposed test routine is likely to give a

stiffness modulus suitable for inclusion in a foundation surface

modulus prediction. Stage 1 is likely to be most appropriate for

the uppermost layer, while Stage 2 may represent conditions in

an underlying foundation layer.

4.2

Design example

By way of example, the data shown in Figure 3 have been used

to generate a design for a UK Highways Agency Class 2

foundation (Highways Agency, 2009) which requires an

equivalent surface modulus of 100MPa under a 240mm thick

asphalt layer. The designation ‘Class 2’ represents the condition

in the finished pavement and it is, therefore, appropriate to use

Stage 4 of the PUMA test, which gives a material stiffness

modulus of 150MPa.

It is also necessary to evaluate the stiffness modulus of the

subgrade soil. This can also be carried out in the PUMA, again

taking Stage 4 conditions for the completed pavement and it is

assumed here that this gave a stiffness modulus of 60MPa.

It is now possible to use multi-layer linear elastic analysis to

determine the equivalent foundation modulus under the

completed pavement. It is suggested here that the most

appropriate design methodology is to compare computed

asphalt tensile strains (the asphalt fatigue cracking design

criterion) under a given load, first with the intended 2-layer

foundation, then with a single layer only, representing the

equivalent foundation with a single stiffness value. On this

basis, 260mm of the gravel material in Figure 3 is required.