1227

Technical Committee 202 /

Comité technique 202

tool, and a work integrated quality control. Thus, local

heterogeneities of the subsoil can be identified, and compaction

with the Impact Compactor can be adjusted systematically. If

necessary, additional compaction passes are conducted.

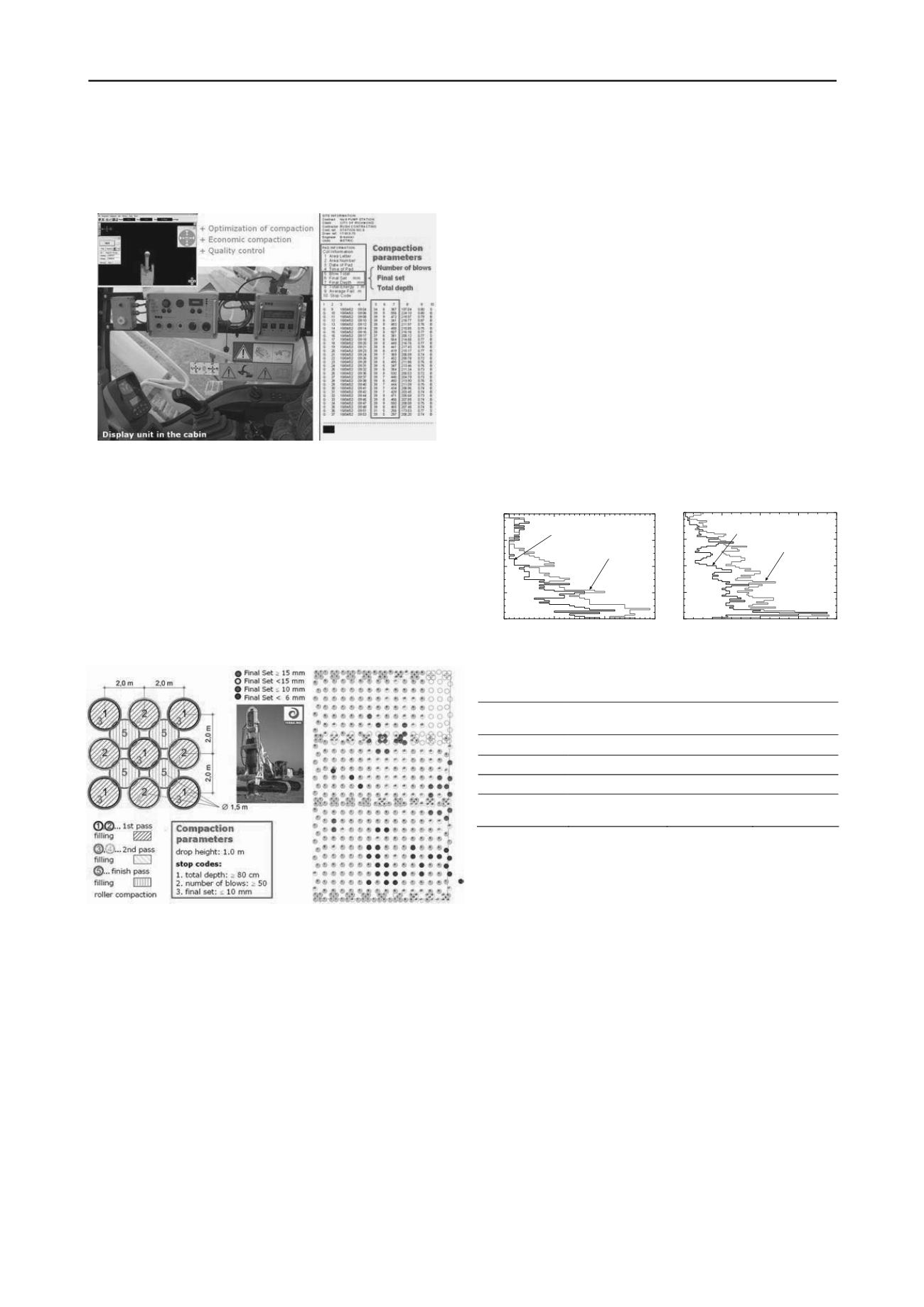

Figure 4. GPS-based recording system of the Impact Compactor.

3.2

Parameter setting and quality control

Optimization and control of compaction with the Impact

Compactor is ensured by meeting the stop code criteria, GPS

based compaction including work integrated documentation of

the performance parameters for each compaction spot, and

conduction of cone penetration tests and/or dynamic probing

before and after compaction. During the compaction process the

following stop codes are applied:

stop code 1: total settlement (depth of the compaction crater)

stop code 2: number of blows per compaction point

stop code 3: final settlement of the last blow

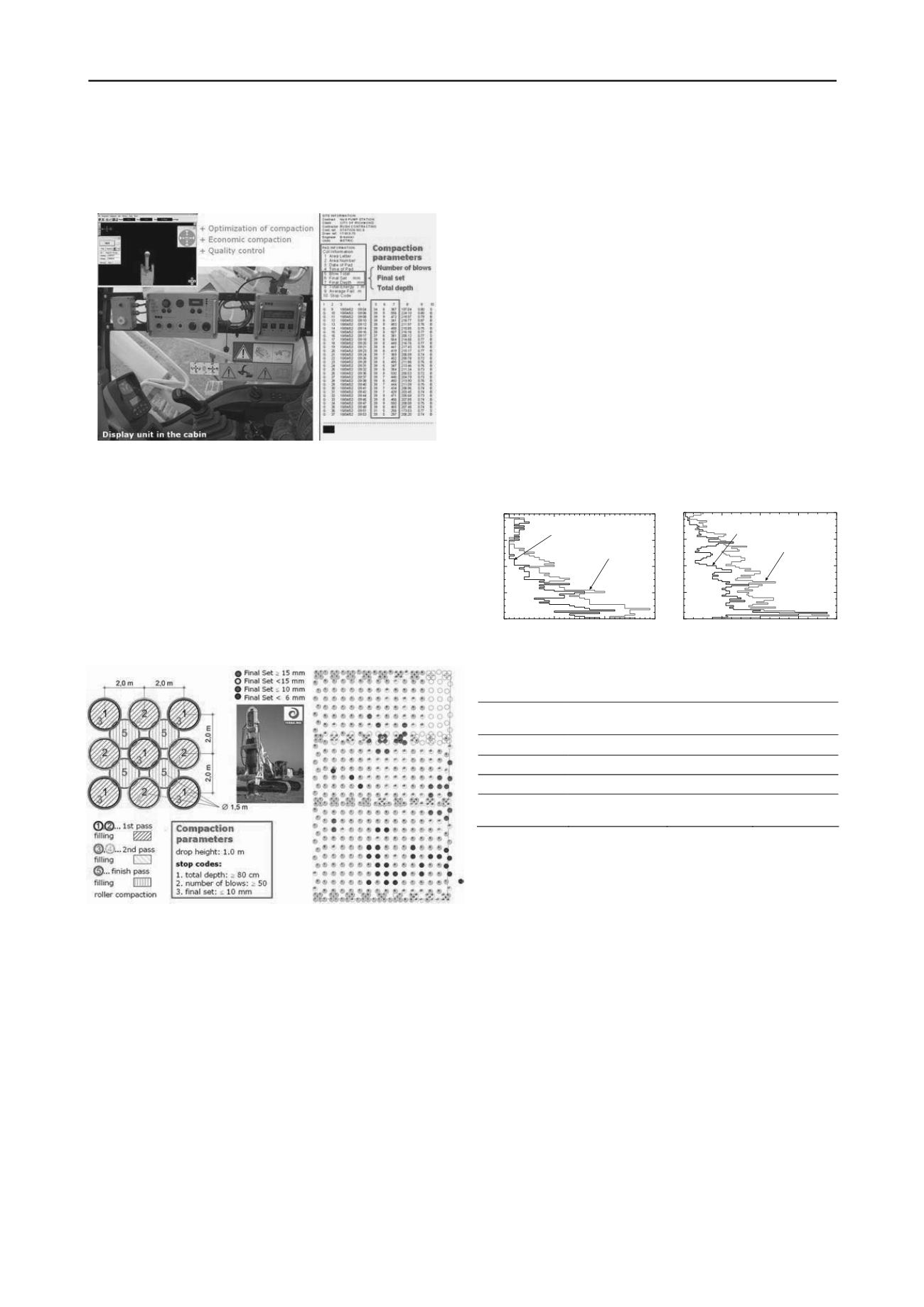

Figure 5: Compaction process (left) and compaction control (right).

The stop codes have to be verified and optimized on a test

field that is located within the site (see Figure 5). In dependence

of the subsoil conditions and the complexity of the project the

calibration field can comprise up to three different compaction

patterns and point grids. The compaction process at the test field

is usually carried out by applying stop codes defined by a

geotechnical expert based on the results and experiences from

comparable sites. After the test compaction the treatment depth

is determined and compared with the required compaction depth

in order to find the suitable compaction point grid. The

compaction pattern and point grids, the number of compaction

passes and the stop codes are finally defined by the geotechnical

expert.

The compaction depth is determined conducting cone

penetration tests (CPT) and/or dynamic probing light, medium,

or heavy (DPL, DPM, or DPH).

In Figure 6 the number of blows N

10

determined by dynamic

probing heavy and light before and after compaction is plotted

against the depth. The dynamic probing heavy was performed in

non-cohesive primarily sandy gravelly soil; the dynamic

probing light was carried out in cohesive soil consisting of silts

and sands. It can be seen that the depth effect of the Impact

Compactor depends on the soil condition, and it varies from

about 4 m (silts and sands) to 7 (8) m (sandy gravelly soils).

In cohesive soils of soft to stiff consistency dynamic probing

heavy allows only a low number of blows independent of the

degree of compaction. Consequently, for checking the

compaction effect it is recommended to use dynamic probing

light (DPL) or cone penetration tests (CPT) (Adam et al. 2010).

Typical depths of influence (treatment depth) are

summarized in Table 1 in dependence of the soil type based on

the results of numerous experimental investigations.

For quality control recorded compaction parameters are

evaluated graphically. As an example, in Figure 5 (right) the

“final set” (stop code 3) is used as control criteria, and the

compaction points are hatched in blue, green, yellow or red

color in dependence on the numerical value of the recorded

“final set”. It can be seen that another compaction pass had to

be carried out on the red colored points. Consequently, this plot

gives information on the compaction quality (whether the stop

codes are met all over the site or not), and allows conclusions to

be drawn about the subsoil quality before compaction.

0

10

20

30

-8

-6

-4

-2

0

before compaction

after compaction

number of blows N10(DPH)

(a)

depth [m]

0

20

40

60

80

-8

-6

-4

-2

0

number of blows N10(DPL-5)

before compaction

after compaction

(b)

depth [m]

Figure 6: Dynamic Probing Heavy (DPH) in non-cohesive soil (left) and

Dynamic Probing Light (DPL-5) in cohesive soil (right).

Table 1. Characteristic compaction depth for the Impact Compactor

ith a falling weight of 9,000 kg mass.

w

Type of soil

Type of dynamic

probing

Number of

blows

Treatment

depth

Sa/Gr

DPH

N

10

> 20

6 – 7.5 (10) m

si Sa

DPH

N

10

> 15

5 – 6 m

sa Si

DPL

N

10

> 20

4.5 – 5 m

Miscellaneous

graded soils

DPL/DPH

N

10

> 15 / 20

4.5 – 7 m

3.3

Vibration emission and immission

On numerous test sites the maximum surface velocity induced

by the Impact Compactor as function of the distance were

determined. The data acquisition tool MR2002DIN-CE (RED

BOX) of the company SYSCOM was applied to monitor and

record the vibrations. The velocities were measured in situ with

tri-axial velocity transducers according to the German Standard

DIN 45669 and saved with a data recorder. The velocity was

measured in three orthogonal directions in the frequency

domain of 1 to 315 Hz. The subsequent data processing was

done with the software package VIEW 2002 (Ziegler

Consultants). Subsequently, regression analyses were performed

to obtain the magnitude of the maximum resulting velocity

v

R,max

as function of the distance from the impact foot.

Figure 7 shows selected linear regression lines for different

homogeneous ground conditions determined through free-field

velocity measurements during impact compaction with a falling

weight of 9,000 kg mass. It is seen that smallest peak velocity

magnitudes develop during compaction of homogeneous loose

sandy gravels. For this subsoil condition a coefficient of decay

of about 1.8 is determined. Note that only one compaction pass

was performed. Largest peak velocity magnitudes were

measured during compaction of dense gravels. Compaction of

sandy silts and gravelly silty sands led to peak velocity

magnitudes in-between. The coefficient of decay of about 1.3 is