684

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

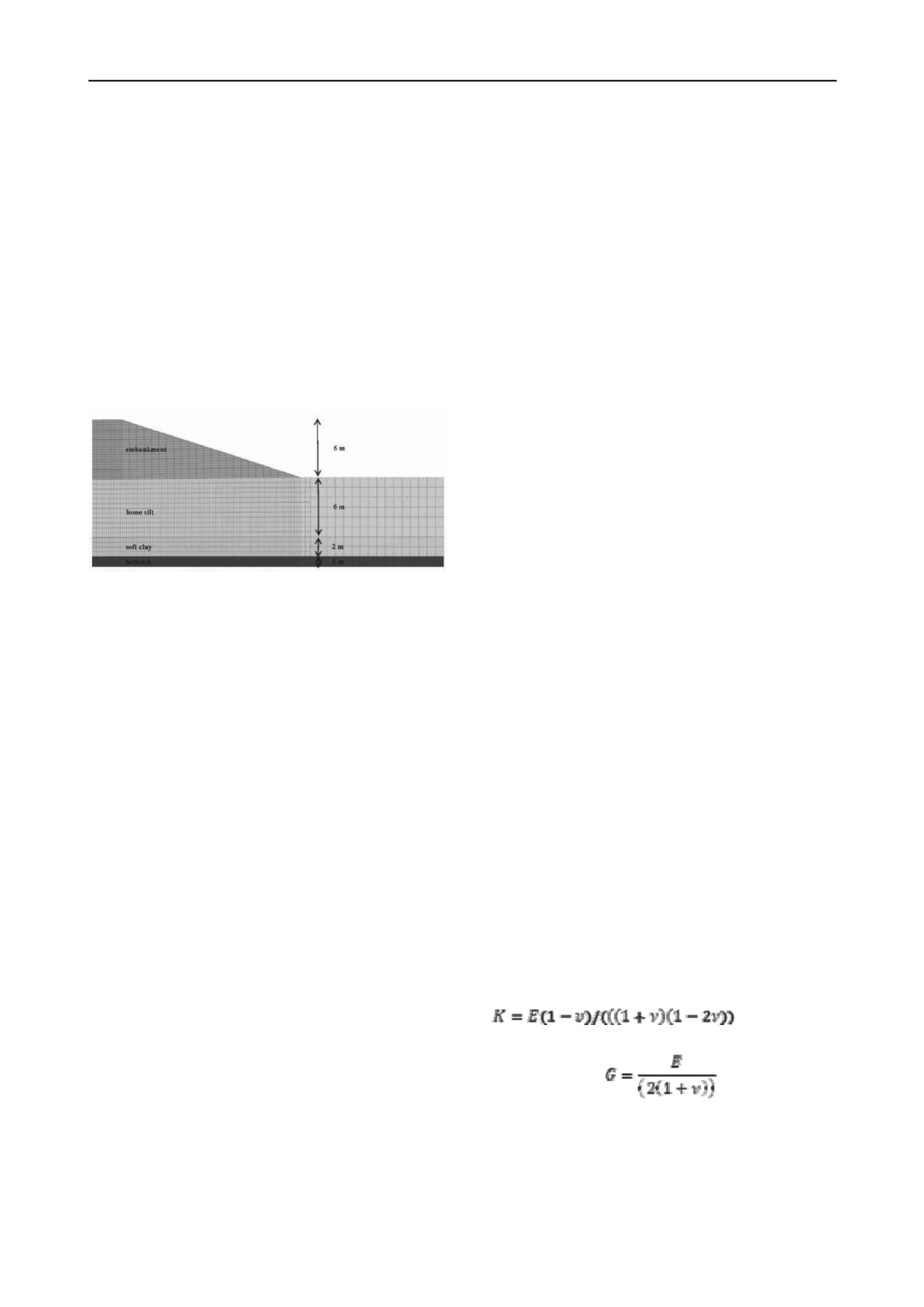

Material properties were defined based on average values

found in the literature review and are described in greater detail

under the section titled Physical Properties. The groundwater

table was assumed to be located at the surface of the loose silt

deposit. The model was built to maintain a maximum aspect

ratio of 3:1 between elements in the x, y, and z directions and

used planes of symmetry to reduce the total number of elements

in each model. The embankment was constructed in several

phases to simulate more realistic loading conditions.

The groundwater table was modeled using a normal

groundwater force rather than using a groundwater flow model.

This was done to simplify the analyses as the behavior of the

groundwater within the soil was not the focus of the study. As a

result the simplified groundwater conditions the Mohr Coulomb

constitutive model was used to simulate soil response.

Figure 1. Model Stratigraphy

3 METHODS OF GROUND IMPROVEMENTS

3.1 Stone columns

Stone columns, like sand drains, enhance the drainage

properties of soft soils, however, the interlocking granular

nature provides additional shear strength to the surrounding

soils compared to sand drains. Stone columns can be installed as

either independent columns or as continuous walls or panels of

columns. Stone columns reduce settlements by promoting soil

arching which transfers the embankment loading to the stiffer

columns once the soft surrounding soils begin to yield (Terzaghi

1943). Typically stone column wall thicknesses and area

replacement ratio (ARR) range between 0.4 and 1.2 m and 10%

to 30%, respectively (Abusharar and Han 2011). Analyses were

completed for stone columns panels with thicknesses of 0.4 m,

0.8 m, and 1.2 m with spacings corresponding to an ARR of

30%.

3.2 Deep mixed columns

Deep mixed columns (DMC) are very similar to stone columns

in terms of typical dimensions, and promoting soil arching to

transfer loading to panels rather than insitu soil. Deep mixed

columns are constructed by mixing lime or cement and insitu

soil to create a column, or panel of columns, of stronger soil

which carries embankment loads and reduces expected

settlements. The primary difference between stone columns and

deep mixed columns is that strength of stone columns is

dependent on the friction angle of the aggregate and

confinement from surrounding soils (Abusharar and Han 2011);

while deep mixed columns have internal strength from

cohesion. It is noted that the deep mixed columns are

constructed such that they are continuous panels and the flow of

groundwater will be inhibited or significantly reduced. For

comparison purposes, panel thicknesses of 0.4 m, 0.8 m, and

1.2 m with spacings corresponding to an ARR of 30% were

used to analyze the efficiency of the deep mixed columns.

3.3 Light weight fill

An alternative to improving the in situ soil in order to increase

the bearing capacity is to reduce the total loading. Light weight

fills such as sawdust, tire derived aggregate, and geofoam are

frequently used during construction of embankments on soft

soils to minimize consolidation, differential settlements, and/or

construction schedules. Analyses were completed using both

sawdust and geofoam as embankment fills, ranging between 2

and 4 m in thickness, to compare against the results of the

ground improvement methods listed above.

3.4 Comparison of methods

Several factors may impact the suitability of each method for a

particular site and may govern which method is selected over

another as follows:

Stone and deep mixed columns cause densification

of the surrounding soil as a result of displacements

during installation. Larger columns and smaller

spacing will increase densification.

Stone columns are highly permeable and therefore

will reduce the liquefaction potential of a material

by allowing excess pore pressures to dissipate.

Specialized equipment is required for construction

of stone/deep mixed columns.

Light weight aggregates may be placed with typical

construction equipment.

Strength characteristics of deep mixed soils may be

influenced by geochemical properties of the

surrounding soil (Jacobson et al., 2003) and thus

rigorous mix designs are recommended for all

sites.

Sawdust may degrade over time due to its organic

nature; however, rates of degradation may be

minimized by limiting exposure to free oxygen and

moisture.

Geofoam is susceptible to rapid degradation when

exposed to hydrocarbons; therefore geosynthetic

liners are often installed.

Cost-benefit comparisons for the different methods are

highly dependent on the location of particular sites and the

availability of materials and therefore have not been included as

part of this study.

4 PHYSICAL PROPERTIES

For the purpose of the parametric study typical values described

in literature or published case studies were used as input soil

parameters for the numerical models. In FLAC3D, the Mohr

Coulomb constitutive model requires wet density, internal angle

of friction, cohesion, tensile strength, and bulk and shear

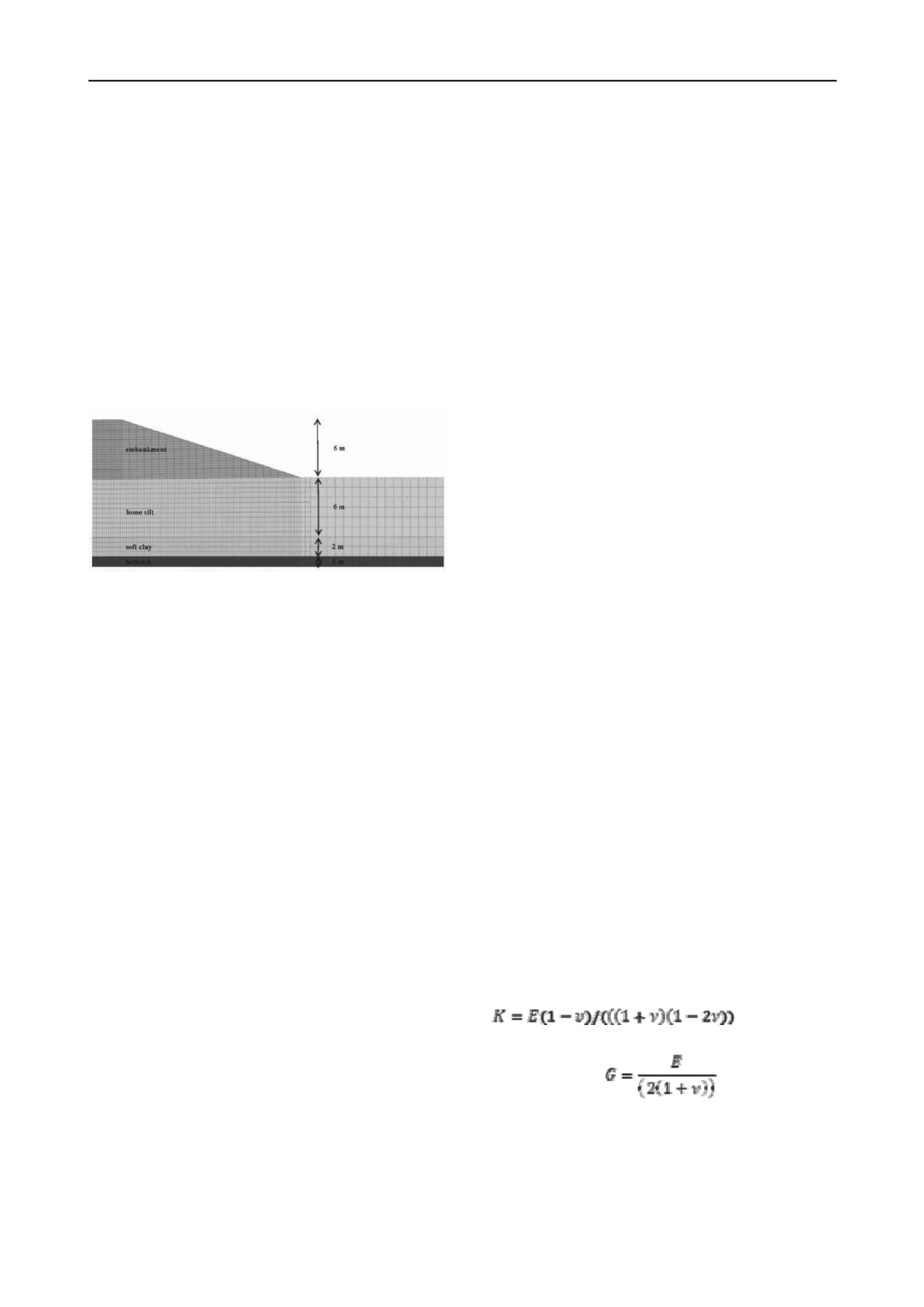

modulii. The bulk and shear modulii are both functions of the

Young’s modulus and Poisson’s ratio of a material that are

calculated using the following equations:

Bulk

Modulus,

(1)

Shear Modulus,

(2)

A summary of the physical and elastic material properties

are provided in Table 1. The material properties were assumed

values unless noted otherwise.