685

Technical Committee 103 /

Comité technique 103

Table 1. Physical Properties

Parameter

(kg/m

3

)

E

(Pa)

Φ

(°)

ν

c’

(Pa)

Bedrock

2200

5

1.93e10

5

30

5

0.38

5

3.0e5

5

Clay

1631 2.00e6

0

0.4

6

1.5e4

Loose Silt

1835 1.24e7

27

0.3

0

Embankment Fill

2039 3.03e7

6

34

0.4

6

0

Stone

1983

2

3.03e7

6

36

2

0.4

6

0

Deep Mixed Soil

1631

1

1.25e9

32

0.2

6

3.4e5

Sawdust

1040

3

8.50e5

32

3

0.05

3

0

Geofoam

15

4

3.76e6

32

0.09

7

1.1e5

4

1

Oliveira et al, 2011,

2

Abusharar and Han, 2011,

3

Rowe and

Soderman, 1984,

4

Geotech Systems Corporation, 1993,

5

Itasca, 2009,

6

Kulhawy and Mayne, 1990,

7

Hazarika, 2006

5 NUMERICAL MODELING RESULTS

To evaluate the efficiency of each method of ground

improvement a baseline model was run which simulated the

construction of a 6 m embankment without neither ground

improvements nor light weight fill. All results have been

normalized against the vertical displacements and vertical

stresses calculated using the baseline model.

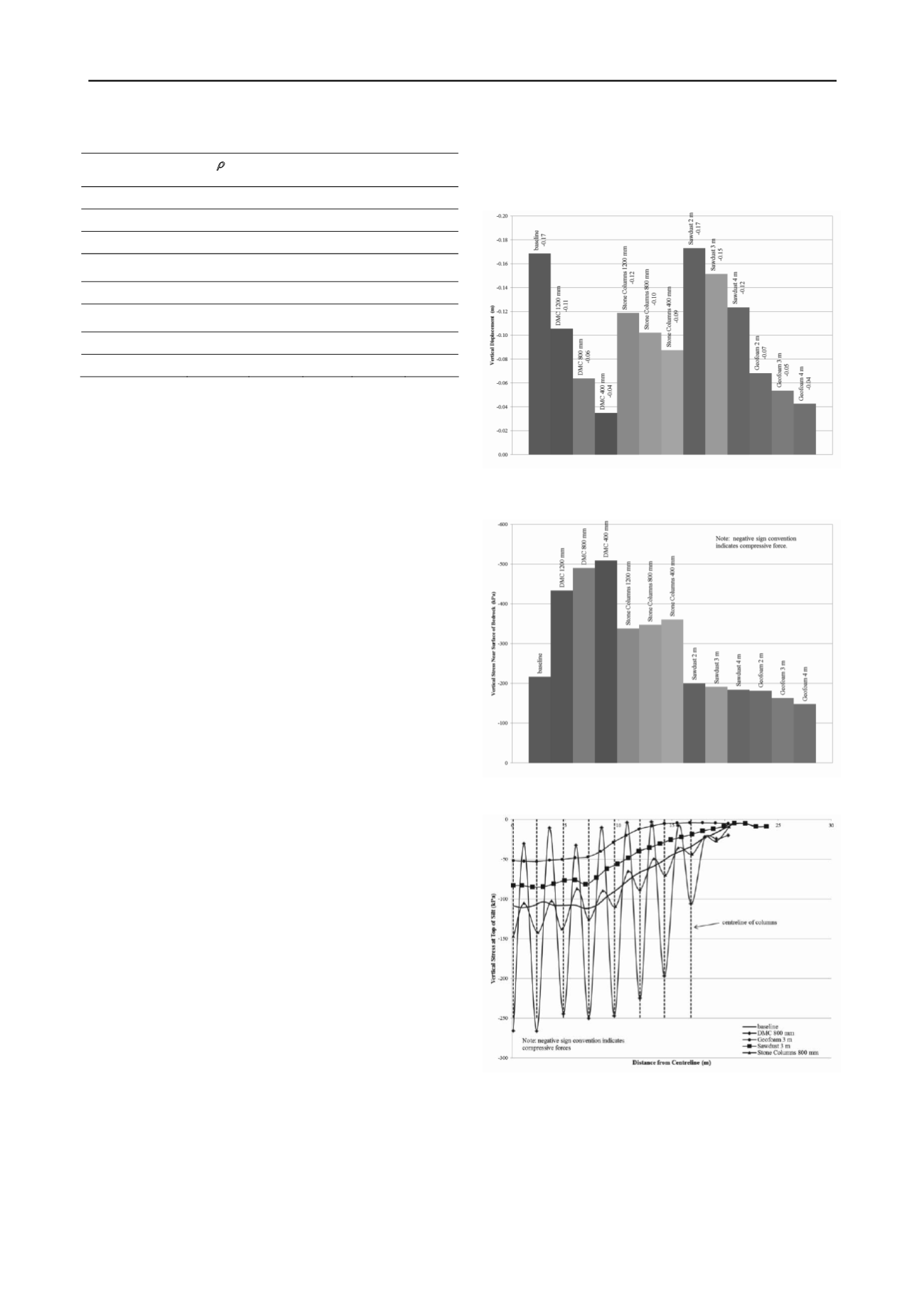

5.1 Settlement

Settlements calculated at the top of the silt layer at the

centerline of the embankment were used for comparisons.

Figure 2 illustrates magnitudes of settlement calculated for each

method. The baseline model predicted a total settlement of

0.170 m. The model with 2 m of sawdust showed negligible

improvement while the models with 4 m of geofoam, and

400 mm deep mixed columns, were the most effective with

predicted settlements of 0.040 m, or a 76% reduction. It can be

seen from Figure 2 that in general the geofoam and the deep

mixed coulmns performed better than the sawdust and the stone

columns with respect to the reduction of settlement.

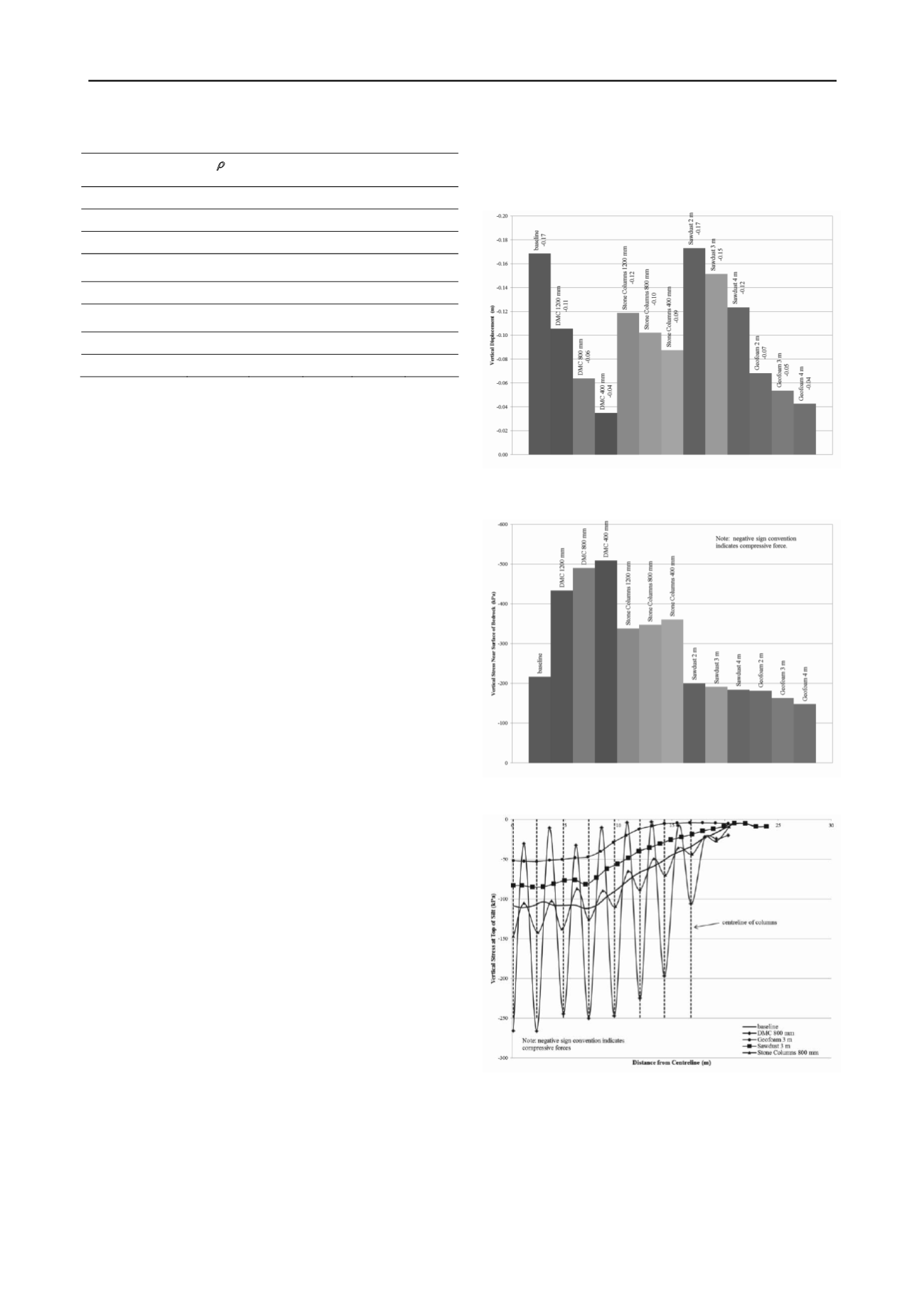

5.2 Vertical stress

Figure 3 shows the maximum vertical stresses calculated near

the surface of bedrock for the different considered ground

improvement methods in comparison to the baseline model. For

illustration purposes only one example for each method is

provided. The following paragraphs include results for all of the

analyses carried out.

The baseline model predicted a vertical stress of 217 kPa

near the surface of bedrock. The model with 4 m of geofoam, as

expected, experienced the greatest reduction in predicted

vertical stresses at 32% of the baseline value, or 68 kPa. The

difference in vertical stress was based on comparison of the

vertical stresses between the respective models and the baseline

calculated at the same point. The stone and deep mixed

columns, as result of the stiffness contrast between the column

material and surrounding soils, are attracting additional loads

due to soil arching. The ability of the stone columns to

accumulate stress from soil arching is limited because the

columns are yielding themselves; however, the trend is still

visible as shown in Figure 4. Figure 5 illustrates how soil

arching reduces the vertical stresses as the column’s diameter

increases to a point at which is becomes less effective. The

percentage difference in vertical stress is based on a comparison

of the vertical stresses calculated at the centerline of the column

and the midspan between columns for each model near the

ground surface. It is noted that the behavior for both types of

columns is very similar and that the overall strength

characteristics will determine the magnitude of the percentage

reduction in stresses. The decrease in soil arching effectiveness

is attributed to the increased spacing between columns. In this

analysis a constant replacement ratio was maintained, therefore,

as the column diameter increased the spacing was increased as

well.

Figure 2. Comparison of predicted settlements at the interface between

the embankment and the ground surface based on different methods of

ground improvements

Figure 3. Comparison of predicted vertical stresses near the surface of

bedrock based on different methods of ground improvements

Figure 4. Comparison of predicted vertical stresses calculated at the top

of the silt layer based on variable methods of ground improvements