459

Technical Committee 101 - Session II /

Comité technique 101 - Session II

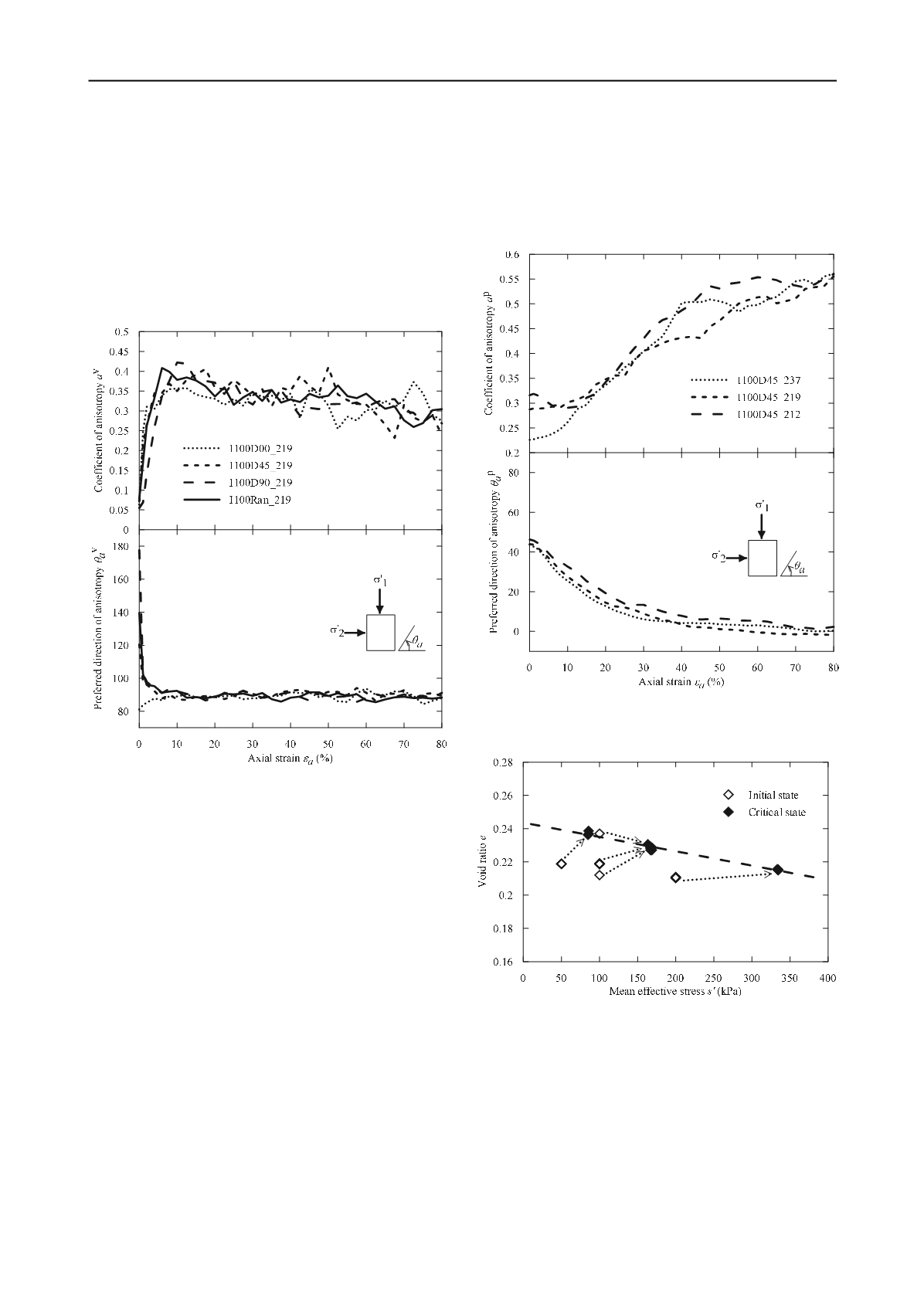

A void space is defined following Li and Li (2009). Figure

3 shows its evolution with shear. It can be seen from the figure

that the void space evolutes from a highly isotropic distribution

prior to shear commencement to an anisotropic one at large

strains with a preferential orientation in the direction of the

major principal stress (

v

90

a

). Substantial amount of

anisotropy is developed within 10% axial strain. Initial fabric

seems to have very little influence on the evolution of void

fabric. Like particle orientation, a unique void fabric is

exhibited at large strain (

v

0.3

a

and

v

90

a

).

Figure 3. Evolution of void space fabric

–

the influence of initial

fabric.

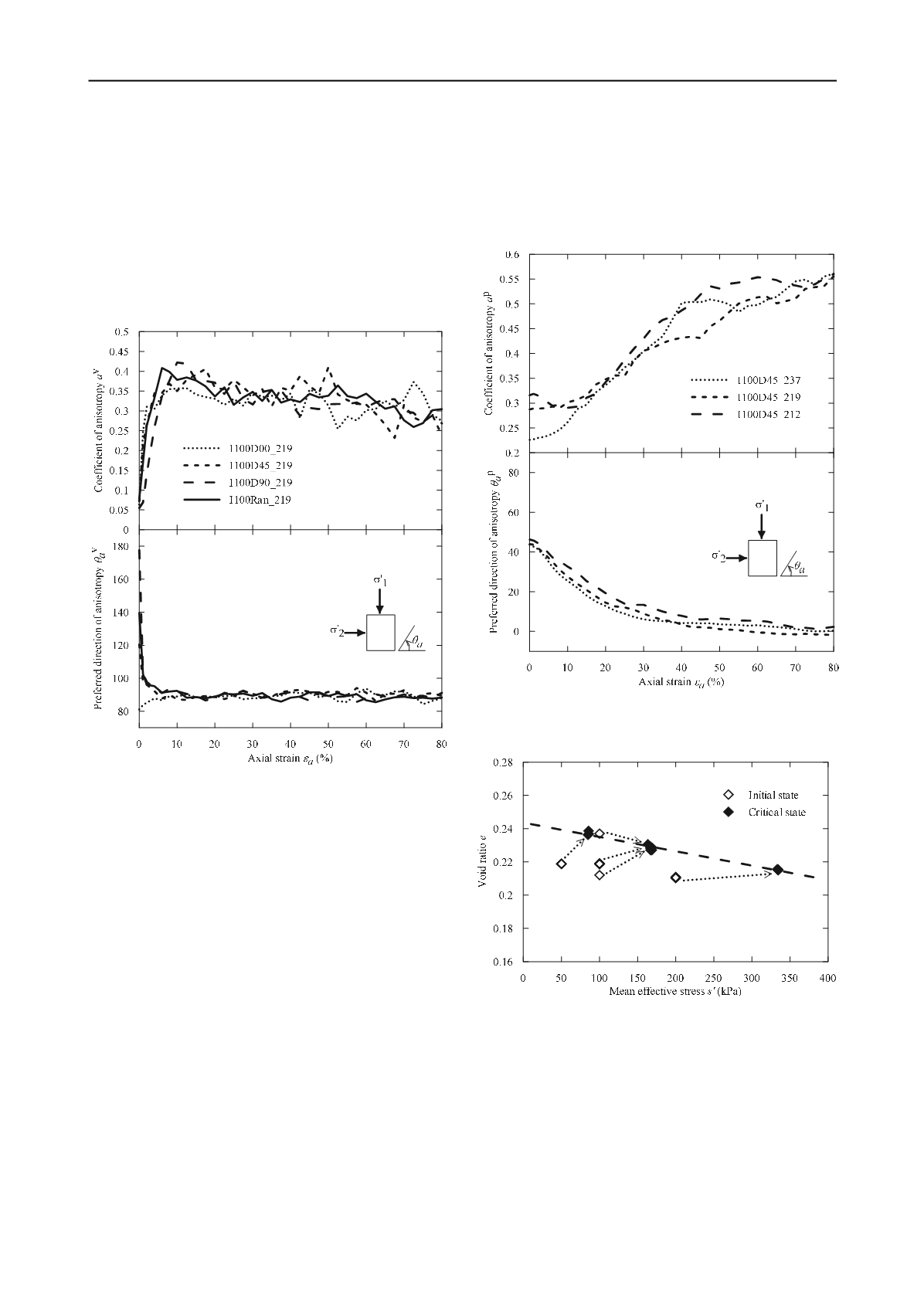

4.2

Influence of initial density

Figure 4 shows the effect of initial density on the evolution of

particle orientation fabric. Deposited assemblages (D45)

confined at 100 kPa having three different initial densities

(initial void ratio from loose to dense = 0.237, 0.219 and 0.212,

respectively) are investigated. Firstly, the particle orientation

fabric changes gradually with increasing axial strain. The

coefficient of anisotropy

p

a

increases gradually with axial

strain while

p

changes from its initial value (45°) to 0°. It

means that the particles align with their long axis perpendicular

to the loading direction when subject to prolonged shearing. A

noticeably anisotropic and unique fabric can be observed at

large strains. The effect of initial density is minimal. The

evolution of void space fabric exhibits very similar behavior as

the one shown in Figure 3, regardless the initial density of the

assemblage.

4.3

Critical state

Figure 5 shows the initial and critical state of the assemblages in

an

e

-

s

’ space where

1

2

'

'

'

/ 2

s

. Initial state of the

specimen includes various void ratios and fabrics confined at

different pressures. It can be seen that a unique line can be used

to describe the critical state. Together with the findings as

revealed from Figure 2-4, it is known that a critical state can be

achieved at very large strains where not only the density and

mean stress reaches a steady value but also a unique fabric is

obtained. Furthermore, the fabric at critical state is correlated to

the loading direction. The results echo the theory proposed by

Li and Dafalias (2012).

Figure 4. Evolution of particle orientation fabric

–

the influence of

initial density.

Figure 5. Initial and critical states of the study assemblages.

4.4

Limitations

The findings of unique fabric at critical state are obtained by

conducting numerical tests limited to monotonic biaxial

shearing of specimens composed of idealized mono-sized pill

shape particles. Tests with continued changing of loading

direction are not considered herein.

5 CONCLUSIONS

A series of numerical biaxial compression tests is undertaken on

idealized two-dimensional granular specimen having various