458

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

preferential orientations could be expected. Generally speaking,

by adopting this approach particles will have their long axis

roughly perpendicular to the gravity field direction (Yan and

Zhang 2013). Another approach is used to create assemblies of

particles having random orientations. In this case, particles with

random orientations are generated inside the model container

and numerical iterations are allowed to achieve an equilibrium

of the assemblage.

A square assemblage having 80 mm in each side is then

extracted from the model container as shown schematically in

Figure 1. An isotropic confining pressure is applied to the

boundary walls of the specimen right after the body force field

is turned off. Isotropic pressure of three different magnitudes is

modeled: 50, 100 and 200 kPa. Attempts are made by

controlling the inter-particle friction coefficient and selecting

appropriate location of the square such that specimens confined

at the same pressure show essentially identical void ratios but

different initial fabrics prior to shear. The difference in void

ratio in all cases is less than 0.0006.

A specimen is labeled by its initial stress, details of specimen

generation method and void ratio prior to shearing. For instance,

I100D90_219 denotes a specimen confined at 100 kPa, formed

by depositing particles from a direction perpendicular to (i.e.,

90°) to the major principal stress direction and had an initial

void ratio of 0.219 before shearing. By the same token,

I50Ran_219 represents a specimen confined at 50 kPa, having

an initial void ratio of 0.219 with particles generated with

random orientations.

To simulate a constant lateral stress biaxial compression, the top

and bottom walls are moved simultaneously and slowly inwards

while the horizontal position of the left and right lateral walls is

continuously adjusted according to a servo-controlled

mechanism to keep the lateral confining pressure at the initial

value. It is to ensure that a quasi-static equilibrium is

maintained throughout the analysis. A compression strain rate

of 2.5×10

-5

% per computational step is used and all the

specimens are sheared to 80% axial strain.

Figure 1. Specimen generation.

3 PARTICULATE FABRIC

Following the pioneer work presented by Oda et al. (1985),

three major sources of fabric are considered in the study. They

are (i) particle orientation, (ii) contact normal; and (iii) void

distribution which are denoted by superscripts p, fn, and v

respectively. Directional information of each fabric parameter is

represented statistically by a rose diagram (Yan and Lin 2013).

Two scalar quantities,

a

and

a

are used to describe the

distribution density

f

n

of the fabric (Rothenburg 1981, see

Equation (1)).

1 cos 2

/ 2

a

f

a

n

(1)

where

n

is a unit vector,

a

is called the coefficient of

anisotropy that characterizes the degree of anisotropy and

0

180

a

describes the preferred direction of the

anisotropy given that

d 1

f

n n

. Clearly 0

a

indicates an

isotropic distribution and the degree of anisotropy increases

with

a

. In this study,

0

a

denotes a direction perpendicular

to the major principal stress. Details of the fabric description

could be found in Yan and Zhang (2013).

4 RESULTS

4.1

Influence of initial fabric

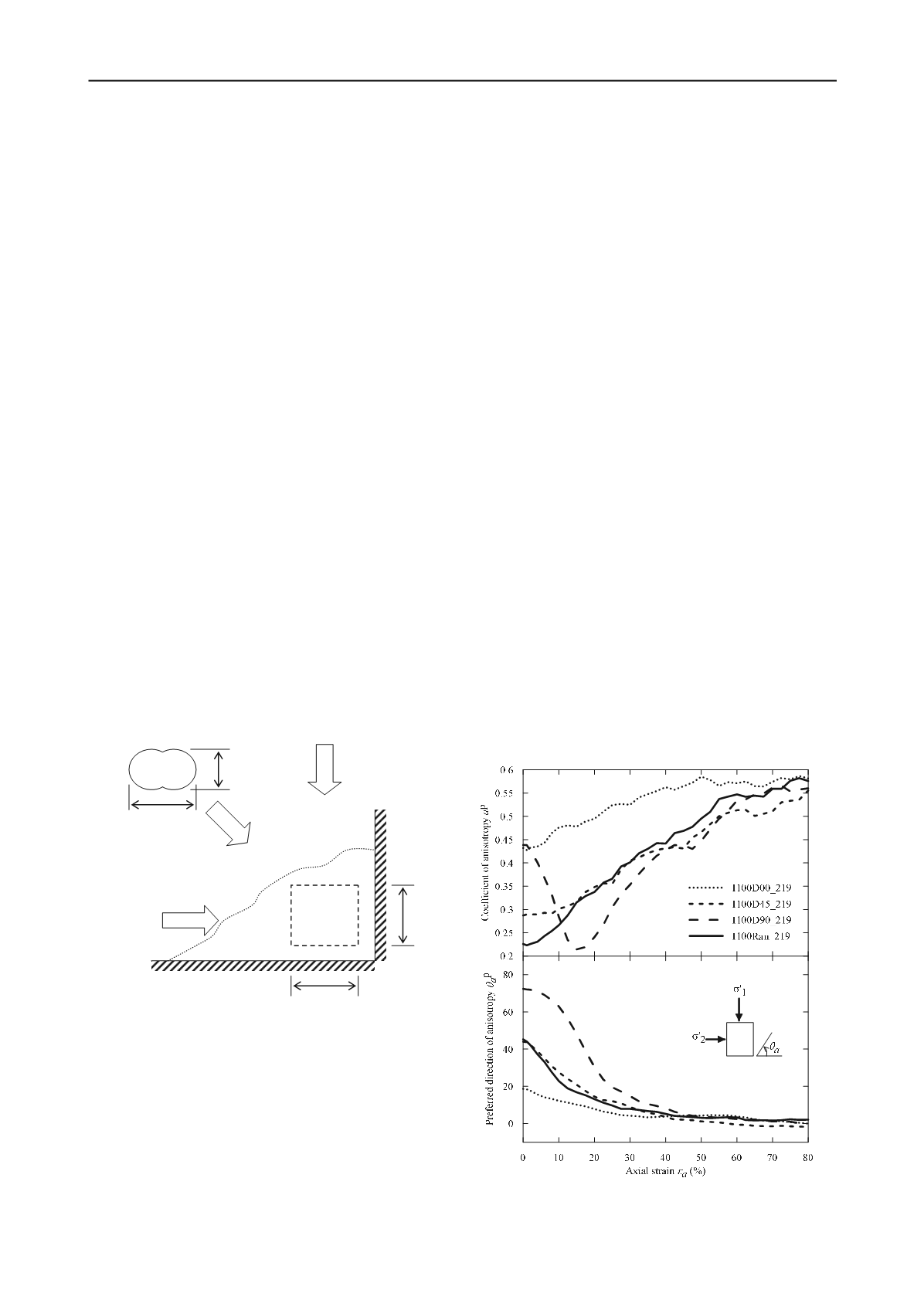

This paper focuses on the evolution of fabric, in particular the

particle orientation and void space, during biaxial shearing. The

stress-strain-strength behavior of the assemblages is not shown

due to the page limitation. It is found that the stresses and

volumetric strain become essentially steady beyond 60% axial

strain. Figure 2 and 3 show the evolution of the fabric of

specimens having identical initial density but different initial

fabric. As shown in Figure 1, specimens having different initial

particle orientations have been created by different methods of

generation. Specimens generated by the particle deposition

method generally show an average particle orientation highly

correlated to the deposition direction. For instance specimen

I100D90_219 shows

70

p

a

before shear, which indicates

that the particles tend to align with its long axis perpendicular to

the deposited direction (D90). Specimens generated by the

deposition method exhibit a higher initial degree of anisotropy

as compared to the one with particles randomly generated. Upon

shearing, particles gradually rearrange in a way that their long

axis becomes perpendicular to the principal stress direction (i.e.,

the shearing direction). Furthermore, a unique fabric of very

similar pair of

p

a

and

p

a

is shown at large strains (

p

0.55

a

and

p

0

a

).

Figure 2. Evolution of particle orientation fabric

–

the influence of

initial fabric.

80 mm

80 mm

D00

D45

D90

particl

1.5 mm

1 mm

Not to scale