394

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Therefore, it is important to determine the degree of correlation

between these two devices to be able to obtain FWD deflections

as a function of Benkelman beam deflections.

2

DEFLECTOMETRY

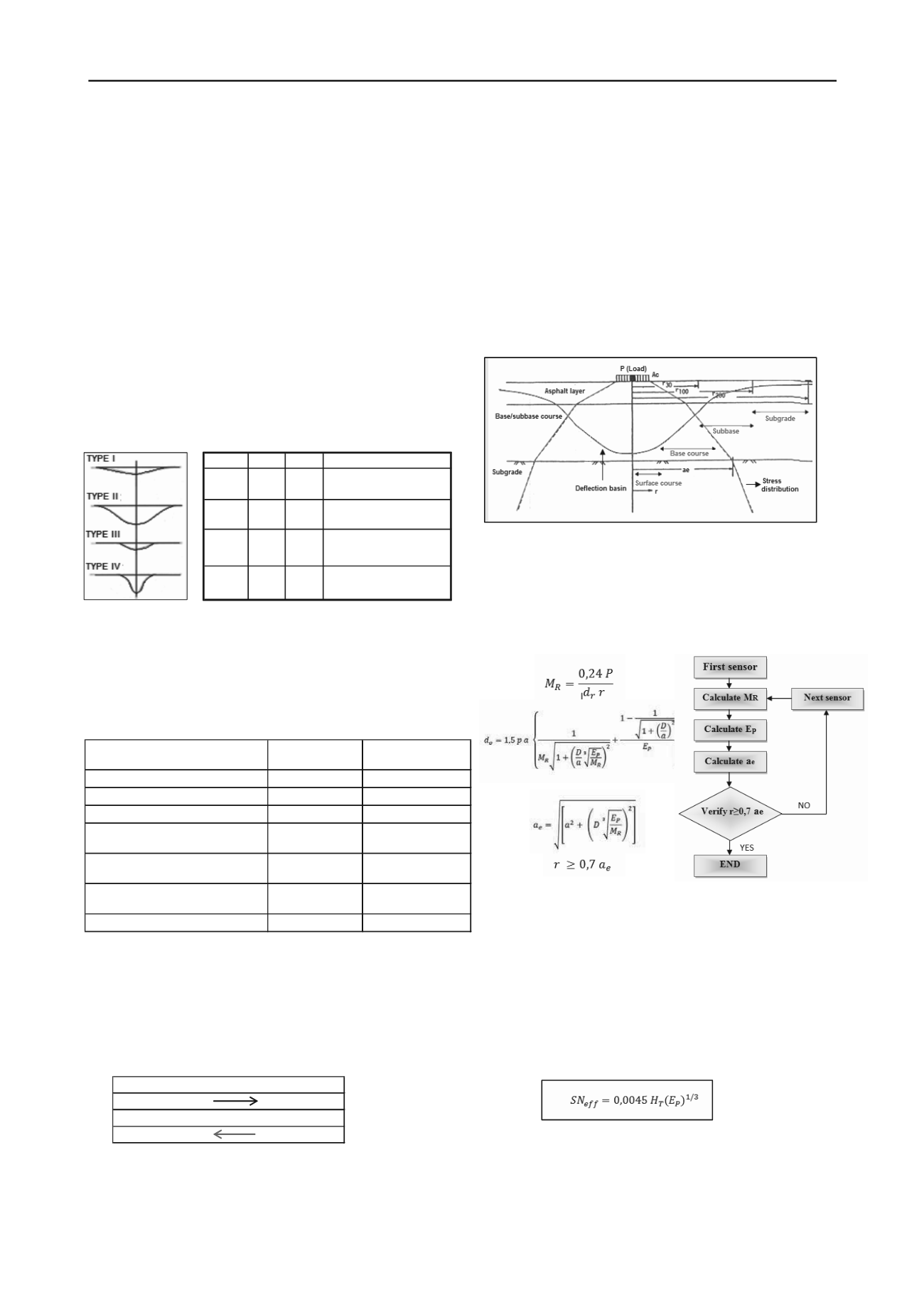

The deflection of an asphalt pavement structure is the vertical

displacement of the surface in response to application of an

external load. When this load is applied on the surface, all layers

are deflected, developing stress and strain in each layer, as shown

in Figure 1.

The shape and dimension of the deflection basin covers important

information about the structural characteristics of both the

pavement and subgrade. Deflections measured towards the end of

the basin reflect the condition of the subgrade, while the

measurements taken in the center of load application reflect the

condition of the surface layer.Figure1 shows the evaluation of the

pavement according to the length (Lo) and a maximum depth (Do)

of the basin.

Figure1.Characteristics of deflection basin

2.1Admissible deflection value

The maximum values of deflection for design purposes

estimated by Hveem (1995) are presented in Table 1.

Table 1. Maximum deflection values estimated by Hveem, 1995.

3

BACKCALCULATION METHODOLOGY

Table 2 shows the basics of back calculation methodology.The

back calculation outputs are the modulus of elasticity of the

pavement structure, effective structural number of the pavement

layers, and subgrade soil resilient modulus.

Table 2. Representation of back calculation methodology

whereE: elastic modulus of the materials, μ: Poisson's ratio, d:

deflection of the pavement structure, σ: stress on each layer of the

structure, ε: strain, and D: layers thickness.There are several

backcalculation methodologies, most of them carried out in

function of the deflections obtained only under dynamic load

including the AASHTO and SASW methodology which was used

for the analysis of the deflections obtained from FWD.( Murillo et

al, 2009).

There exist few methodologies developed from deflections under

static load, because these procedures do not simulate adequately

the real effects of moving loads. Mario Hoffman, in 1975,

presented a methodology based on the "Hogg Model", which was

used in the present study for backcalculation procedure based on

the deflections obtained using the Benkelman Beam.

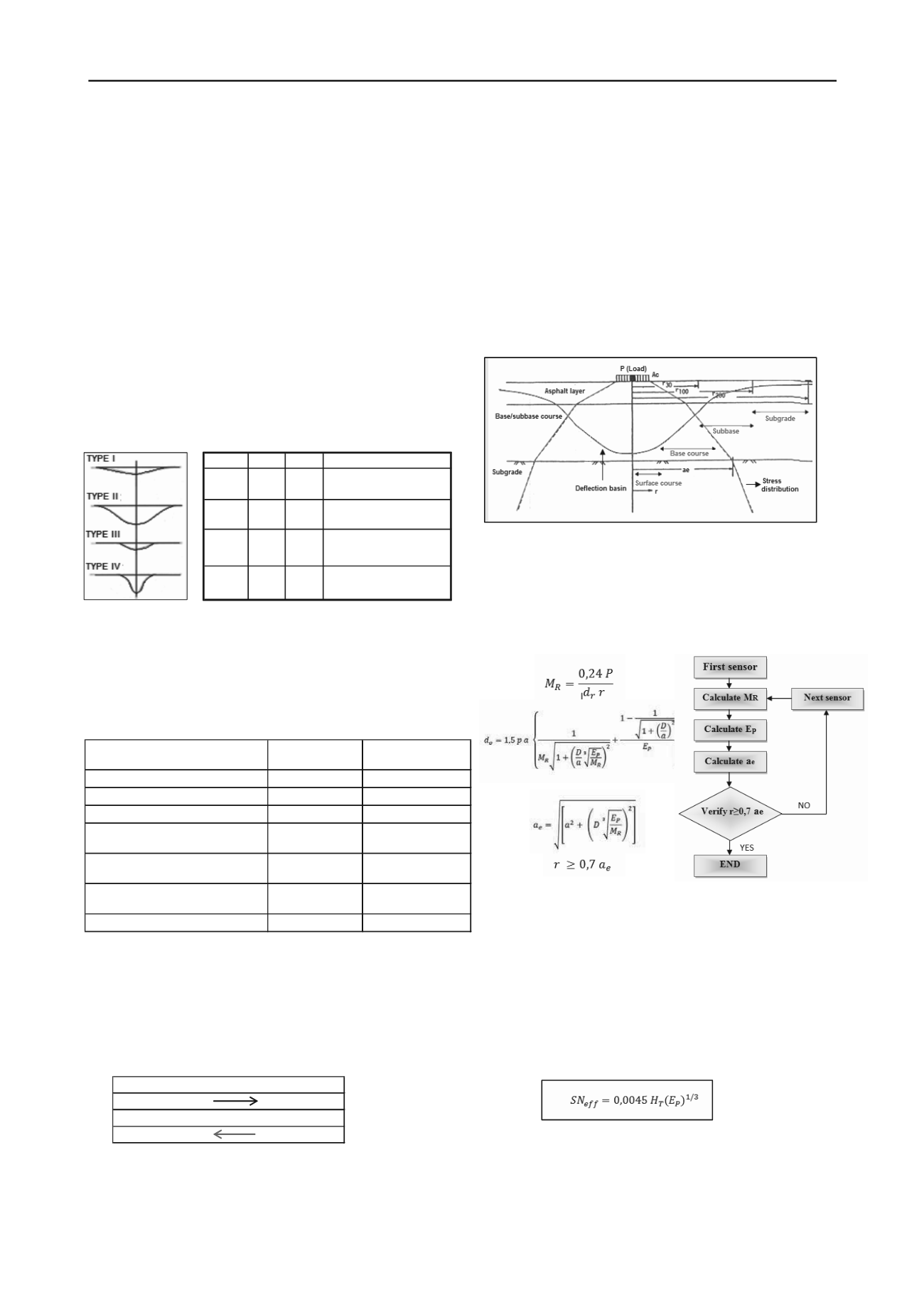

Figure 2.Algorithm backcalculation of M

R

- AASHTO.

3.1.

AASHTO Methodology (for FWD)

The guide for designing of pavement structures AASHTO es-

tablishes a procedure to calculate the resilient module (M

R

)and

thereafter the effective structural number (pavement structural ca-

pacity) as shown in the flowchart of Figure 2.

whereMR: resilient modulus of the subgrade (psi), P: applied load

(pounds), r: distance from the center of the load (inch), d

r

:

deflection at a distance "r" from the center of the load (inch), a

e

:

radius of the bulb of pressure representing the subgrade level

(inch), a: radius of the loading Ring (inch), D: thickness of the

pavement structure above the subgrade (inch), Ep: equivalent

modulus of all pavement layers above the subgrade (psi), d

0

:

deflection at the center of the load plate, adjusted to a temperature

of 20

⁰

C (inch), p: pressure of load plate (P/πa2).The effective

structural number (SN

eff

) is calculated based on the total thickness

of the pavement and its effective modulus as shown below.

(1)

Type Do Lo

EVALUATION

I

Low High

Good subgrade soil/

Good pavement

II

High High

Poor subgrade soil/

Good pavement

III

Low Low

Good subgrade soil/Poor

pavement performance

IV High Low

Poor subgrade soil /Poor

pavement performance

Type of pavem structure

Thickness (mm)

Maximum deflection

value (microns)

Concrete pavement

200

300

Cement treated base

150

300

Asphalt pavement

100

425

Asphalt pavement

base course

(plant mixed)

75

500

Asphalt pavement on base course

(plant mixed)

50

625

Asphalt pavement on base course

(In‐situ)

25

925

Surface treatment pavement

13

1250

ent

on

DIRECT CALCULATION

E, Di,μ d,σ,ε

BACKCALCULATION

E

,σ,ε d, Di,μ