390

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

The pipette method itself was introduced by Middleton in

1930 as a means of determining the erosion potential of a soil.

The difference in the methods was that the samples collected in

the pipette consisted of particles of a maximum diameter of

0.05mm (Middleton, 1930). Volk’s method was, however,

preferred because studies in the southwest of the United States

indicated that the dispersion of the clay fraction (< 0.005 mm

diameter), was more significant in assessing the piping potential

of soils (Decker and Dunnigan, 1977).

The SCS involvement in earth dam construction in the

United States increased in the 1940’s and early 1950’s. The

dispersion test was employed as a routine procedure for all

samples submitted to SCS Laboratories. It was during this

period that the test procedure was adapted to use a hydrometer

instead of a pipette (Decker and Dunnigan, 1977). The

procedure is specified in ASTM standard D422-63 for Particle

Size Analysis of soils (ASTM International, 2007a & b).

With the increased use of the dispersion test and the growth

of the SCS testing facilities in the 1950’s and 1960’s, a few

inconsistencies were detected, such as, the test was not always

reproducible in the same laboratory, and there appeared to be

differences in the results between laboratories. Studies revealed

that water quality and moisture contents of the samples were

responsible for these errors and as such distilled water and in

situ moisture contents were specified (Decker and Dunnigan,

1977). Since that time, there appear to have been no discussions

in the literature regarding any anomalies encountered during

testing.

3 EVALUATION OF CURRENT TESTING METHODS

The test methods for hydrometer analysis currently in use are

the American standards (ASTM International, 2007), the British

standards (BSi, 1990) and the South African Technical Methods

for Highways - TMH1 (NITRR, 1986). Table 1 summarizes

procedures carried out for each test standard, focusing on the

main aspects of the testing procedure.

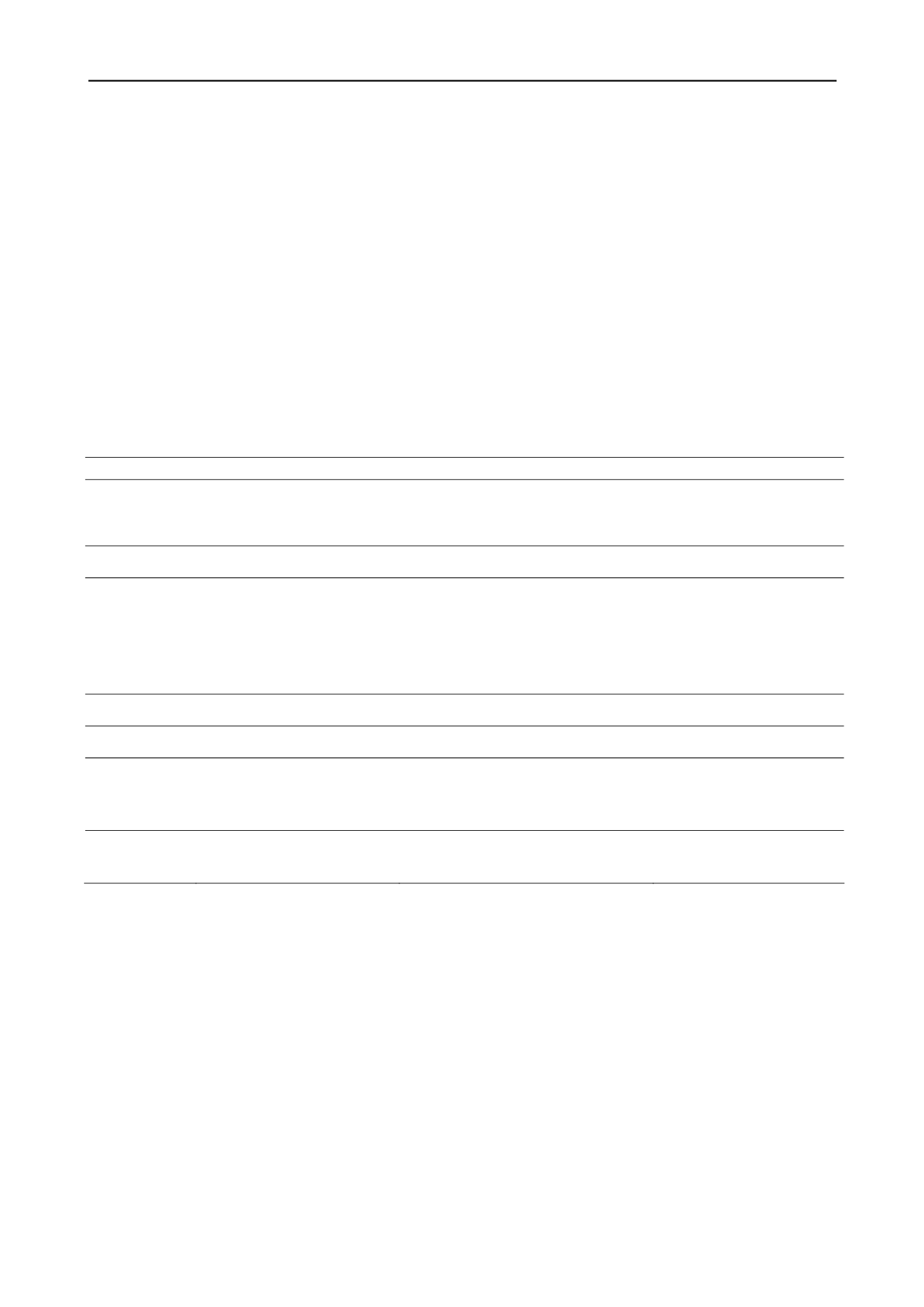

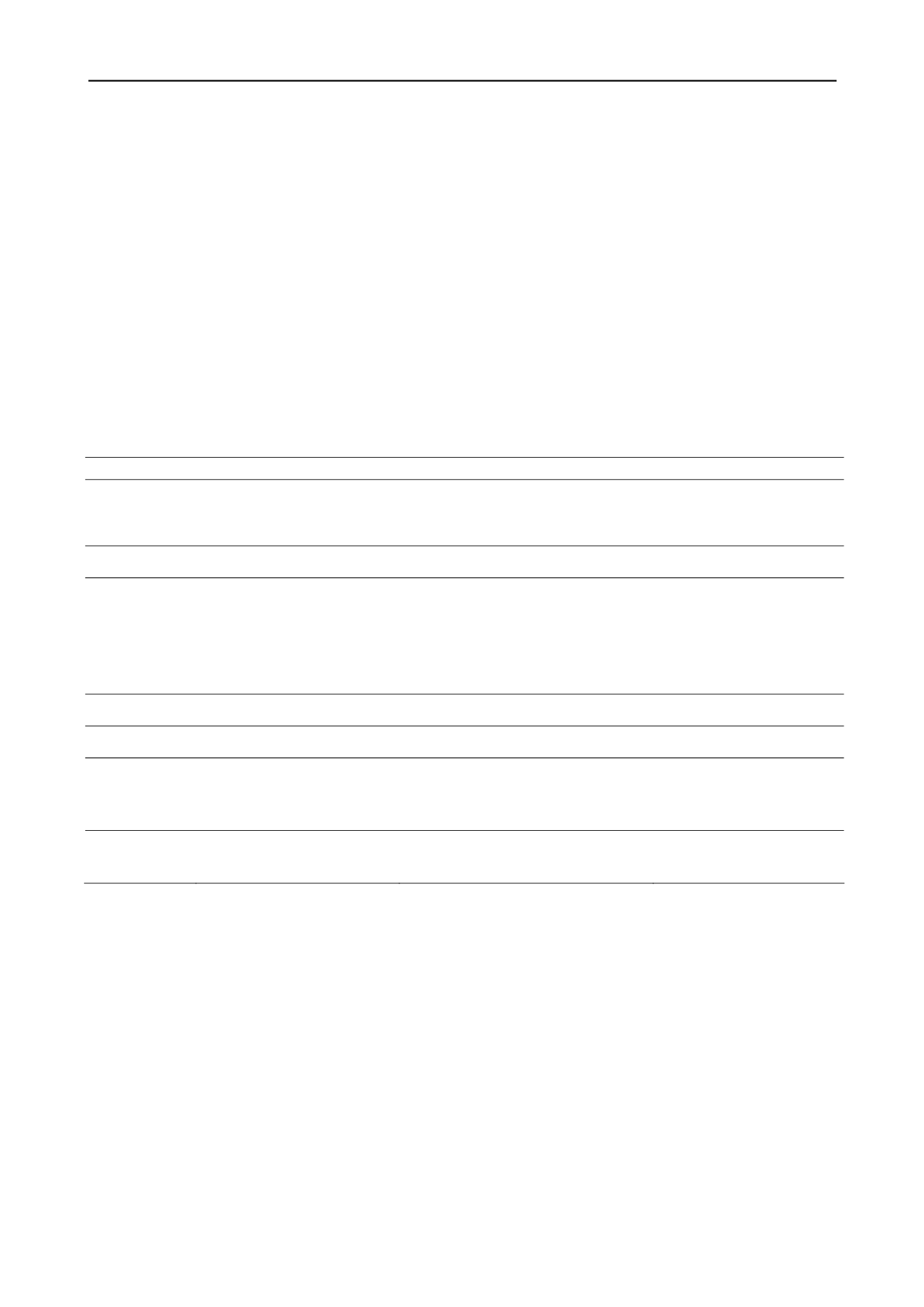

Table 1: Difference in testing procedures used for the determination of the clay fraction of a soil.

Property

ASTM- D422-63

BSi- BS 1377-2: 1990

TMH1- 1986 (A6)

Amount of dry

soil required for

the test:

100g of sand sized particles (i.e.:

particles less than 2mm in size) or

50g of soil fines if material has a

high percentage of silt/ clay.

Depends on type of soil, i.e.: 100g for sandy

soil, 50g for silty soil and 30g for clayey soil.

100g of soil fines (i.e.: particles

less than 0.425mm in size) or 50g

of soil fines if material has a high

percentage of silt/ clay.

Pre-treatment

None

With hydrogen peroxide if organic matter

present.

None

Dispersing agent

125mℓ sodium hexametaphosphate

solution at 40g/ℓ.

100ml sodium hexametaphosphate solution

comprising 33g Na-hexa. + 7g Na-carbonate in

distilled water to make 1 ℓ of solution.

NB: If soil does not disperse completely, allow

soil to settle, decant as much of the water as

possible and then add a further 100mℓ of

dispersant.

5 mℓ each of sodium silicate and

sodium oxalate solutions.

Soaking

Samples soaked for minimum of 16

hrs.

Soak in solution for min of 4hrs or overnight.

Minimum period of 2 hrs but

preferably overnight.

Hydrometer

readings

Taken at 2min; 5min; 15min; 30min;

1h; 4h and 24h.

Taken at 8min; 30min; 2h; 8h & 24h.

Taken at 18s, 40s & 1h.

Analysis

Equations used to calculate

maximum diameter of particles in

suspension

Equations used to calculate maximum diameter

of particles in suspension.

Maximum particle size calculated.

At 1h, max size is 0.005mm, at

40s max size is 0.05mm and at

18s, max size is 0.075mm.

Temperature

Constant temperature at or near 20°C

is required.

Constant temperature bath of 25°C, to an

accuracy of ± 0.5°C.

20°C when readings are taken or a

temperature correction has to be

applied.

Close observation of these test procedures illustrates little

variation in the method of determination of the dispersion ratio,

except with regard to the types of dispersing agents used. The

ASTM and BSi standards specify that sodium

hexametaphosphate be used as a dispersing agent. However, the

solution is prepared differently and at different proportions in

each standard. The volume required to disperse the sample in

the test is also very different.

TMH1 specifies that a combination of sodium silicate and

sodium oxalate be used as the dispersing agent. A study of the

past revisions of the South African standards shows that the

combination of sodium silicate and sodium oxalate was

specified in the 1958 and 1986 test methods, whereas, sodium

hexametaphosphate was specified as the standard dispersant in

the 1970 version. There is no reason found as to why the

combination of sodium silicate and oxalate is used instead of

sodium hexametaphosphate or why there was a change in the

standard in 1970.

It should also be noted that TMH1 states that the one hour

hydrometer reading indicates the percentage of the clay fraction

in the sample. Analyses using Stoke’s Law show that at one

hour, particles in suspension in all samples are in the range of

0.006 – 0.007 mm, which is silt-sized and not clay-sized.

4 TESTING EQUIPMENT AND METHODS USED

A study was conducted to evaluate the effects of the different

methods on the test results. For the study, testing procedures

that were carried out were the South African standard (TMH1)

and the American standard (ASTM), the primary difference in

the procedures, being the variation in dispersing agents. The

tests were carried out on three samples, one non-dispersive, one

highly dispersive and a third that was presumed to be moderate

to slightly dispersive (based on past experience and field

observations).

The dispersing agents used were combinations of sodium

hexametaphosphate (33g) plus sodium carbonate (7g) in a liter

of water and a sodium silicate (5mℓ) plus sodium oxalate (5mℓ)

solution. Samples were left to stand for approximately 16 hours

after dispersion before being mechanically agitated and then the

hydrometer readings were taken. Time intervals for the

hydrometer readings were at 1 hour, 40 seconds and 18 seconds

as specified in TMH1 Method A6. Duplicate samples were