379

Technical Committee 101 - Session II /

Comité technique 101 - Session II

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Measured

LS

DS

Measured

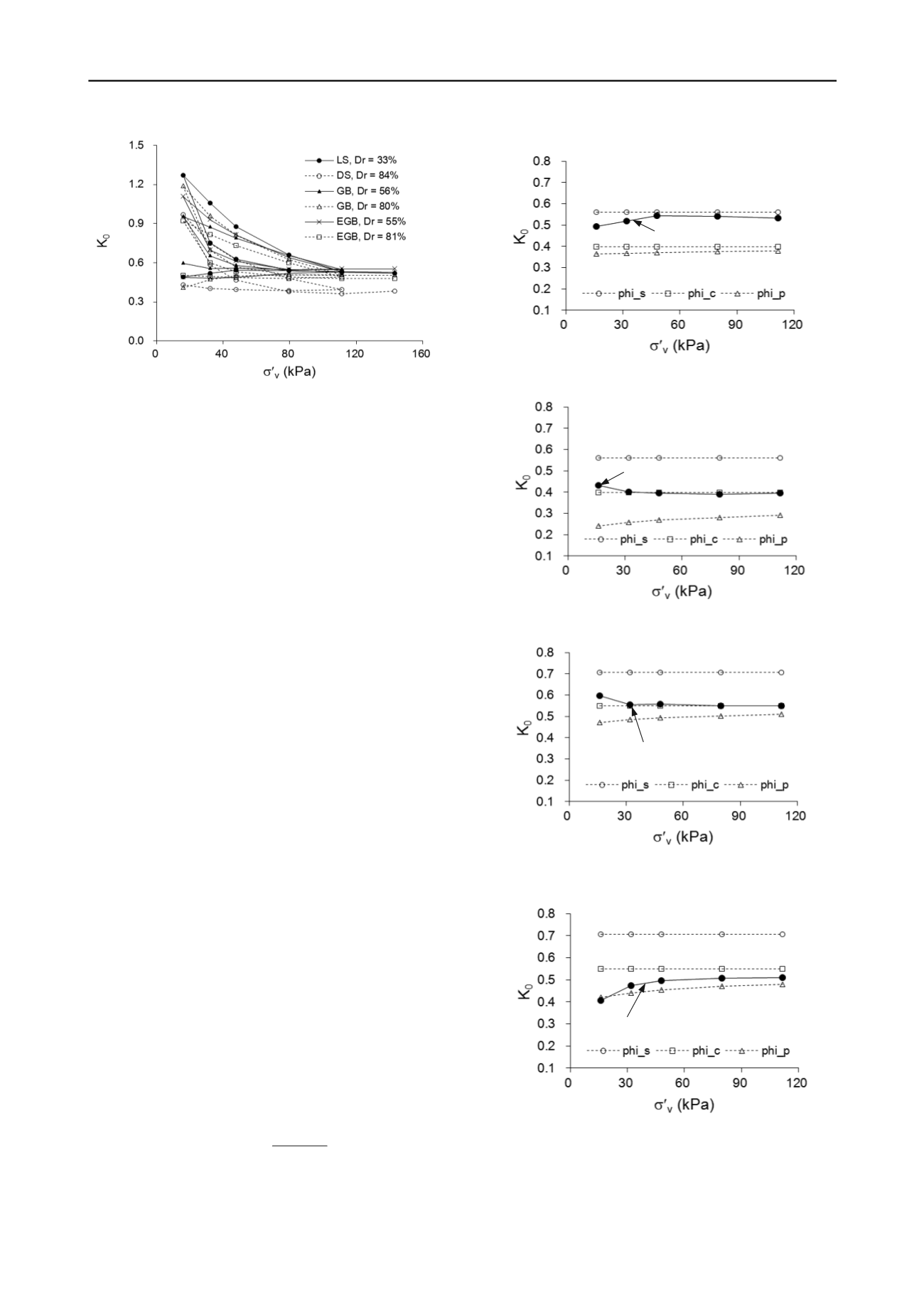

Fig. 3 Values of K

0

with

v

for test granular materials of Jumunjin sand

(LS and DS) and glass beads with and without etching (GB, EGB).

vertical stress direction due to higher interlocking, which leads

to lower K

0

during loading. The horizontally interlocked stress

induces the increase of K

0

during unloading whereas the partial

release of the horizontal stress during reloading makes the

evolution of K

0

run between loading and unloading stages. Once

the stress reaches the preconsolidation stress, K

0

remains

constant as the normally consolidation condition prevails.

The effect of particle shape and angularity on K

0

was

investigated by directly comparing the test results from

Jumunjin sand and glass beads. In Fig. 3, the values of K

0

for

the dense sand (DS) are compared with those for glass beads

(GB) according to the vertical stress. The lower values of K

0

for

the dense sand are manifest presumably due to the angularity

effect. The particle surface roughness effect on K

0

values can

be analyzed by comparing the test results from glass beads (GB)

and etched glass beads (EGB). No marked difference of K

0

between GB and EGB is observed during loading, while GB

exhibits higher K

0

values during unloading and reloading. The

ratio between the artificially created surface dents (e.g., ~5 to 10

m) and particle diameter ranges from 0.01 to 0.02 for EGB,

which impose insignificant impact on K

0

during loading, while

the particle geometry is predominant.

4.2

Correlation to Strength

The shear strength of granular materials can be described using

different definitions of friction angle. The critical state friction

angle

c

, the peak friction angle

p

, and dilatancy angle

are

the typical examples. The inter-particle surface friction angle

s

can be regarded as another type of friction angle that contributes

to the overall shear strength of granular materials.

The confining stress within the specimen for the thin-wall

oedometer tests continuously increases upon loading. The

changes in confining stress result in changes in dilatancy and

thus in the peak friction angle. Following Bolton (1986), the

effect of confining stress and relative density on the peak

friction angle can be evaluated using the following relationship:

R D c

p

I R

(5)

where R

D

= dilatancy ratio = 3 and 5 for triaxial and plane-strain

conditions, respectively. The dilatancy index I

R

is defined as:

R

p

Q I

I

A

pm

D R

100

ln

(6)

where I

D

= relative density as a number between 0 and 1; p

A

=

reference stress = 100 kPa;

pm

= mean effective stress at peak

in the same unit as p

A

; and Q and R = intrinsic soil variables.

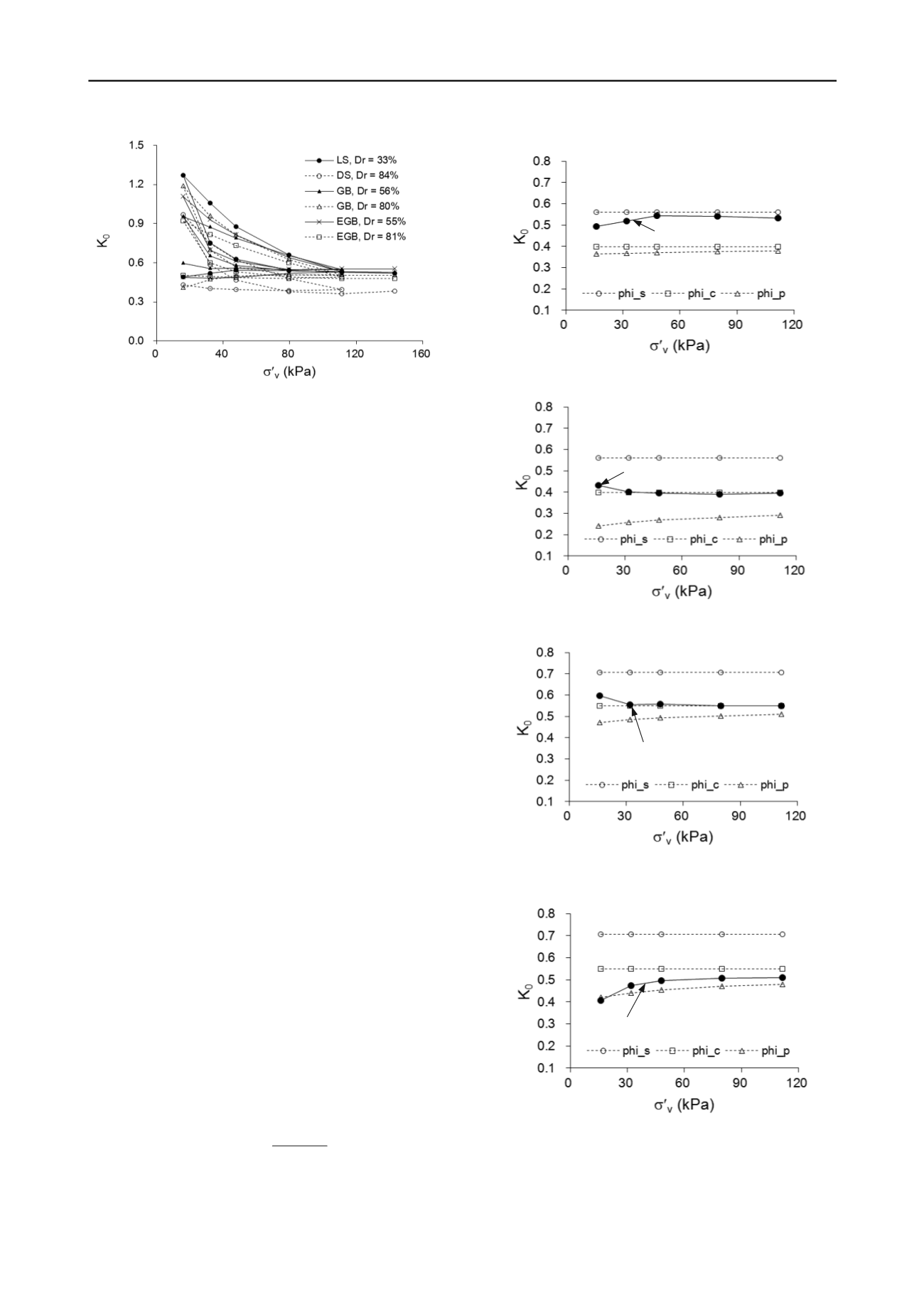

(a)

(b)

(c)

(d)

Fig. 4 Measured and calculated K0 values with

v

for (a) loose sand;

(b) dense sand; (c) medium etched glass beads; and (d) dense etched

glass beads.

GB, Dr = 56%

Measured

GB, Dr = 80%

Measured