378

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

OCR

K K

NC

,0

0

(3)

where K

0,NC

= K

0

for normally consolidated conditions, OCR =

overconsolidation ratio, and

= exponential parameter. Mayne

and Kulhawy (1982) and Mesri and Hayat (1993), for example,

proposed sin

for

.

Although the Jaky

’

s K

0

equation have been widely used and

modified to better reflect the actual stress state, uncertainties

still exist, which has not been fully clarified yet. Examples are

the effect of particle characteristics, which differ inherently for

different materials, and the correlation to the friction angle

that is not constant but varies state-dependently.

3

TESTING PROGRAM

3.1

Materials

A series of laboratory tests were conducted to investigate and

analyze the K

0

evolution of granular materials. Three different

granular materials were adopted, which include Jumumjin sand,

spherical glass beads (GB), and etched glass beads (EGB). The

use of different granular materials was aimed to investigate the

effect of inherent particle characteristics, such as particle shape,

surface roughness, and angularity, on K

0

in more

straightforward and systematic manner. Jumunjin sand particles

were sieved, and the particles ranging between 0.425 mm and

0.85 mm (e.g., sieves #40 and #20) were collected and used in

the test, to presumably minimize the effect of fines content and

to make test samples equivalent in size hence directly

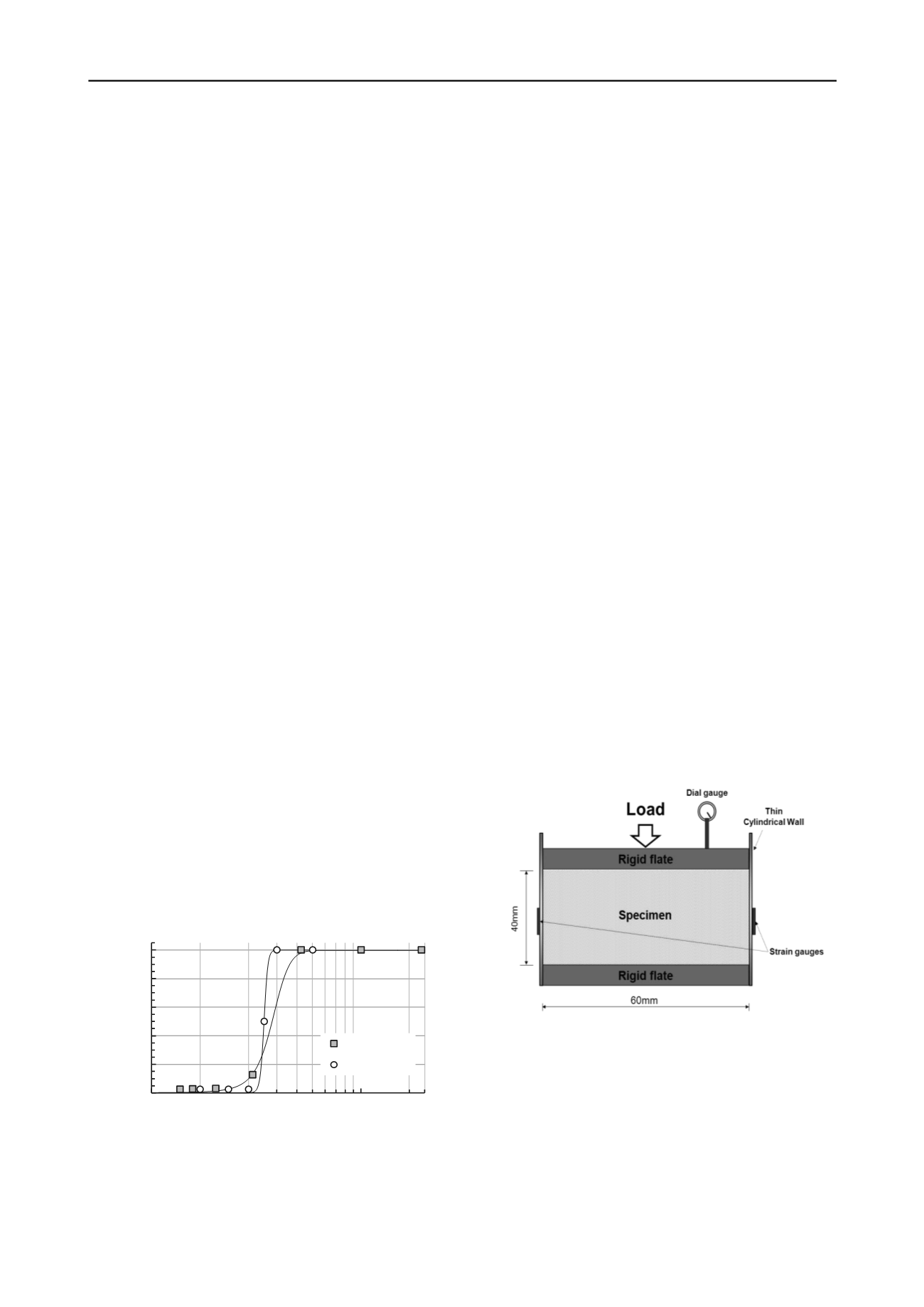

comparable to glass beads. The grain size distribution of

Jumunjin sand is shown in Fig. 1, in comparison with glass

beads. Sand particles are uniformly distributed with the mean

particle size D

50

of around 0.56 mm.

The soda lime glass beads (CaO-MgO-Na

2

O-SiO

2

) with

spherical particle shape and smooth surface (D

50

~ 0.5 mm)

were selected as comparative materials. The surface roughness

was controlled by etching clean, smooth glass bead surfaces

with hydrogen chloride-based solution (HCl, pH=1

0.5). Glass

beads were submerged in the hydrogen solution for 15 seconds

and were thoroughly rinsed with deionized water followed by

oven-drying at 80

o

C. This process produced uniformly etched

glass beads with rough surfaces, while the same spherical shape

as clean glass bead particles was maintained. Three samples

were then subjected to the assessment of K

0

measurements.

The values of

c

were 37.1

, 26.7

, and 30.0

for Jumunjin

sand, glass beads, and etched glass beads, respectively. The

values of

p

varied, depending on the relative densities and

particle characteristics considered in the tests.

Fig. 1 Grain size distribution curves of test materials.

3.2

Determination of K

0

The various test devices have been proposed to measure K

0

that

satisfy the radial strain limit, smaller than 5

10

-5

(Okochi and

Tatsuoka, 1984). The radial expansion of either membrane or

thin-wall tube can be servo-controlled to maintain the zero

lateral strain condition whereas the complex stress path and

multiple measurement systems are involved. Alternatively, the

strain gauges are attached to the thin-wall tube and the

horizontal stress is directly related to the cell deformation

within acceptable strain regimes (Zhu et al. 1995; Kolymbas

and Bauer 1993).

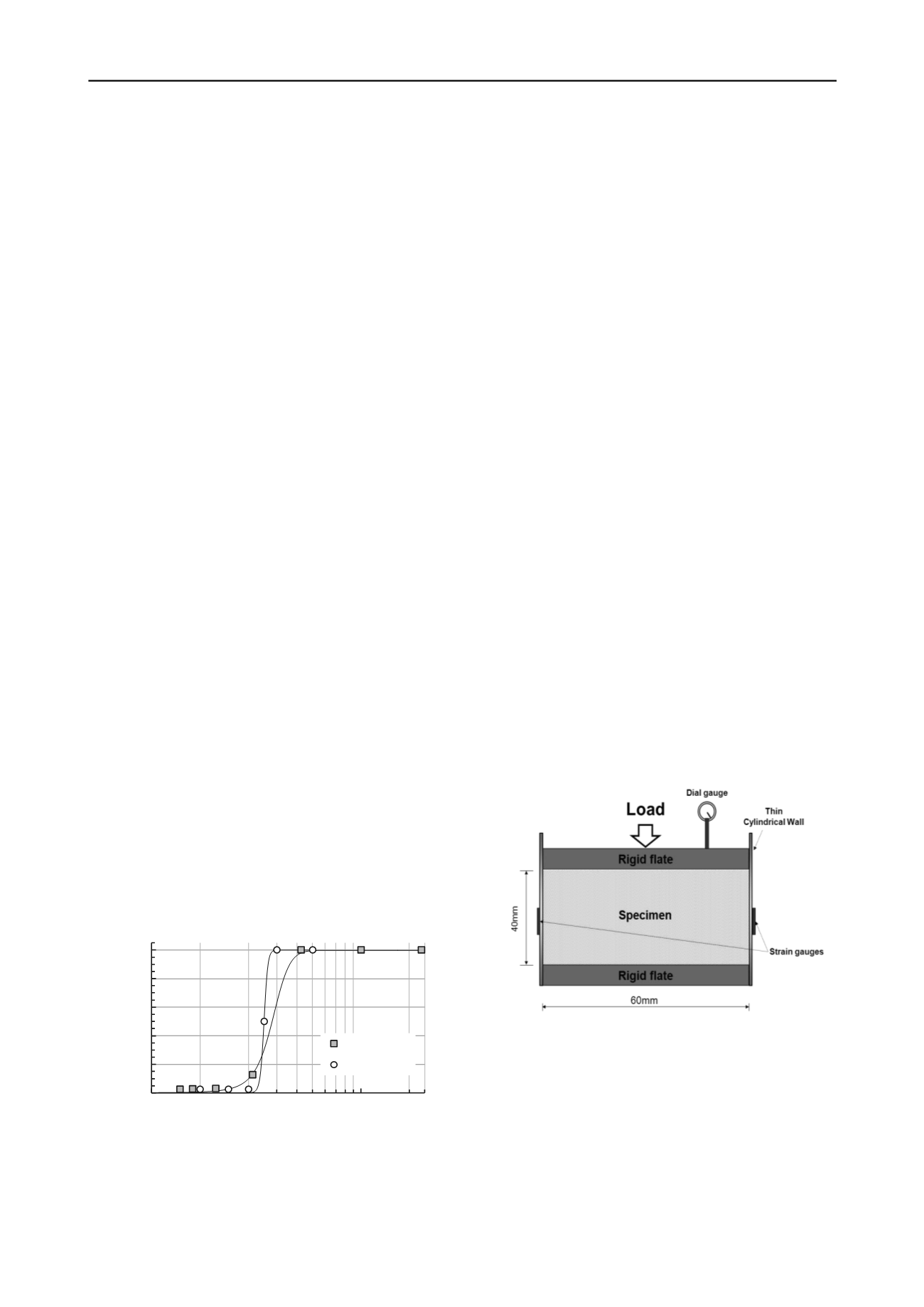

The oedometer method to measure K

0

adopted in this study

consists of a thin aluminum cylinder of 0.13 mm in thickness

and 66 mm in diameter. A pair of strain gauges (120ohm, CEA-

13-240UZ-120, Vishay) was attached at the middle height of the

cylinder outside and another pair of dummy gauges was

included for temperature compensation forming the full-bridge

circuit. The sample height is about 40 mm with a height to

diameter ratio equal to 0.61. Fig. 2 illustrates the experimental

configuration and peripheral electronics. The voltage response

of strain gauges was calibrated and correlated to the horizontal

stress using a water-filled balloon inside the cylinder, assuming

that the applied vertical stress is equal to the horizontal stress.

The linear calibration factor was then obtained and given as

follows:

8338 4

0476 0

.

V .

(4)

where

is the horizontal stress in the unit of kPa and V is the

voltage out in the unit of mV.

Dry samples were placed in the thin-wall oedometer to

achieve a target relative density and were subjected to loading-

unloading-reloading cycles. The maximum loading reached 111

kPa and reloading ran up to 143 kPa beyond the

preconsolidation stress. The voltage response was recorded

every 1 sec and each loading step lasted 5 to 10 minutes. The

horizontal stress for a given loading step was computed by

averaging voltage response and by applying the calibration

factor. The test specimens were prepared at different relative

densities of D

R

= 33% and 84% for Jumunjin sand and D

R

=

56% and 80% and D

R

= 55% and 81% for glass and etched

glass beads, respectively.

Fig. 2 Configuration of thin-wall K

0

test.

4

TEST RESULTS AND ANALYSIS

4.1

K

0

for Different Test materials

The changes of K

0

with

v

for the test materials measured from

the thin-wall oedometer are shown in Fig. 3 during the whole

loading cycles. As shown for the loose (LS) and dense (DS)

sands with D

R

= 33 and 84%, respectively, the K

0

values of the

dense sand run below the loose one at all the loading stages.

The dense sand provides the strong force chain along the

0

20

40

60

80

100

0,1

2

Percent finer [%]

Grain Size [mm]

sand

glass beads