222

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

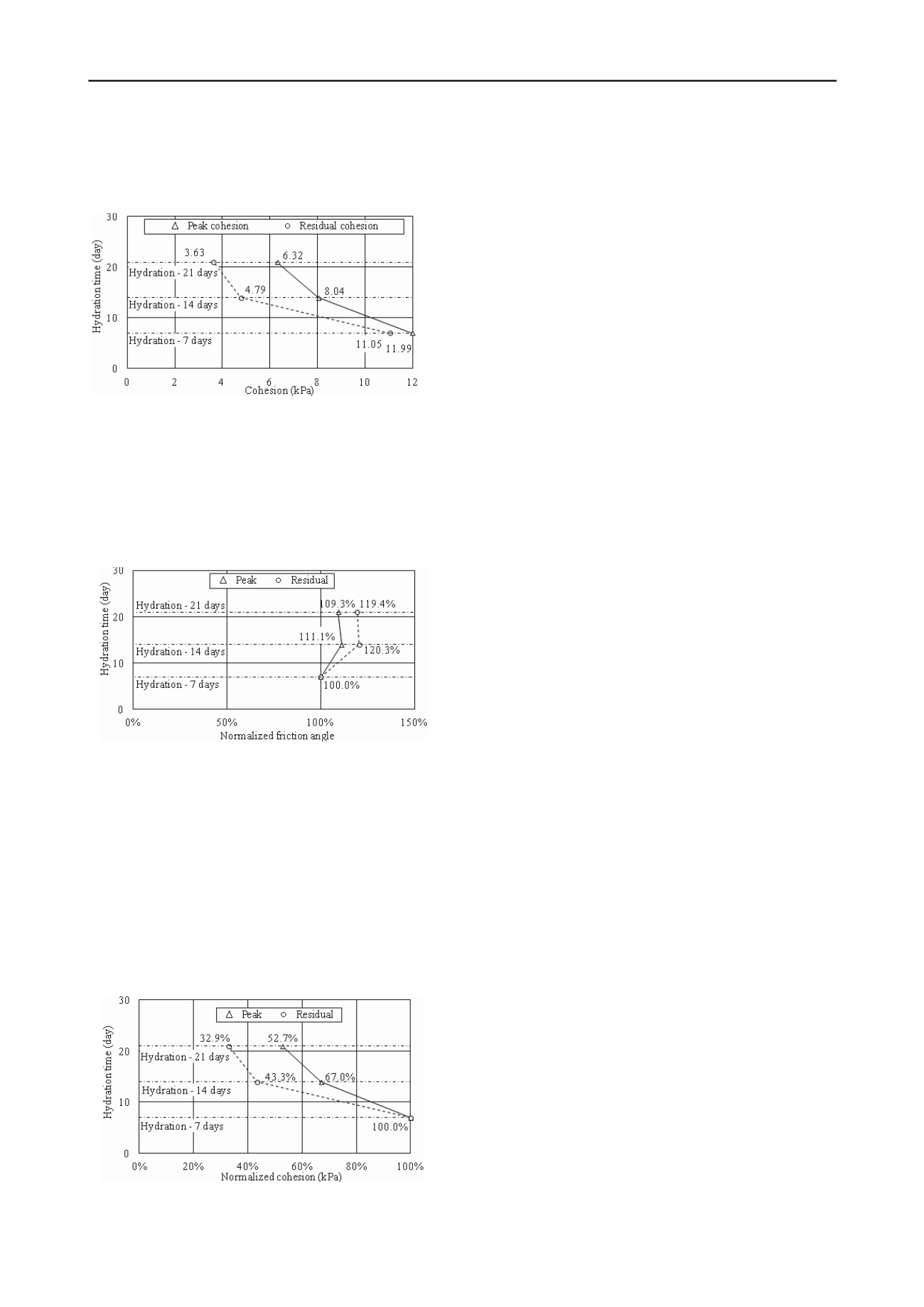

Figure 6 presents the correlation between peak and residual

cohesion and the time of hydration. Observing the change in

cohesion, it is evident that cohesion decreases constantly with

longer hydration times.

4

CONCLUSIONS

Test results show that the swelling of bentonite clay is a long-

lasting process. Tests carried out on the Volclay sample have

shown that the primary swelling stage is completed after 31

days, regardless of the normal stress intensity. After primary

swelling, the stage of secondary compression and creep

develops. The extent of swelling and secondary compression

depends on the normal stress levels.

The analysis of shear strength parameters of specimens hydrated

for 7, 14 and 21 days shows decreasing cohesion with extended

times of hydration. When hydration time is longer than 14 days,

the intensity of change in cohesion decreases. The intensity of

change in residual cohesion in the first 14 days of hydration is

higher than for peak values, presumably as a result of increasing

pore pressure during the shear stage.

Figure 6. Hydration time vs. cohesion.

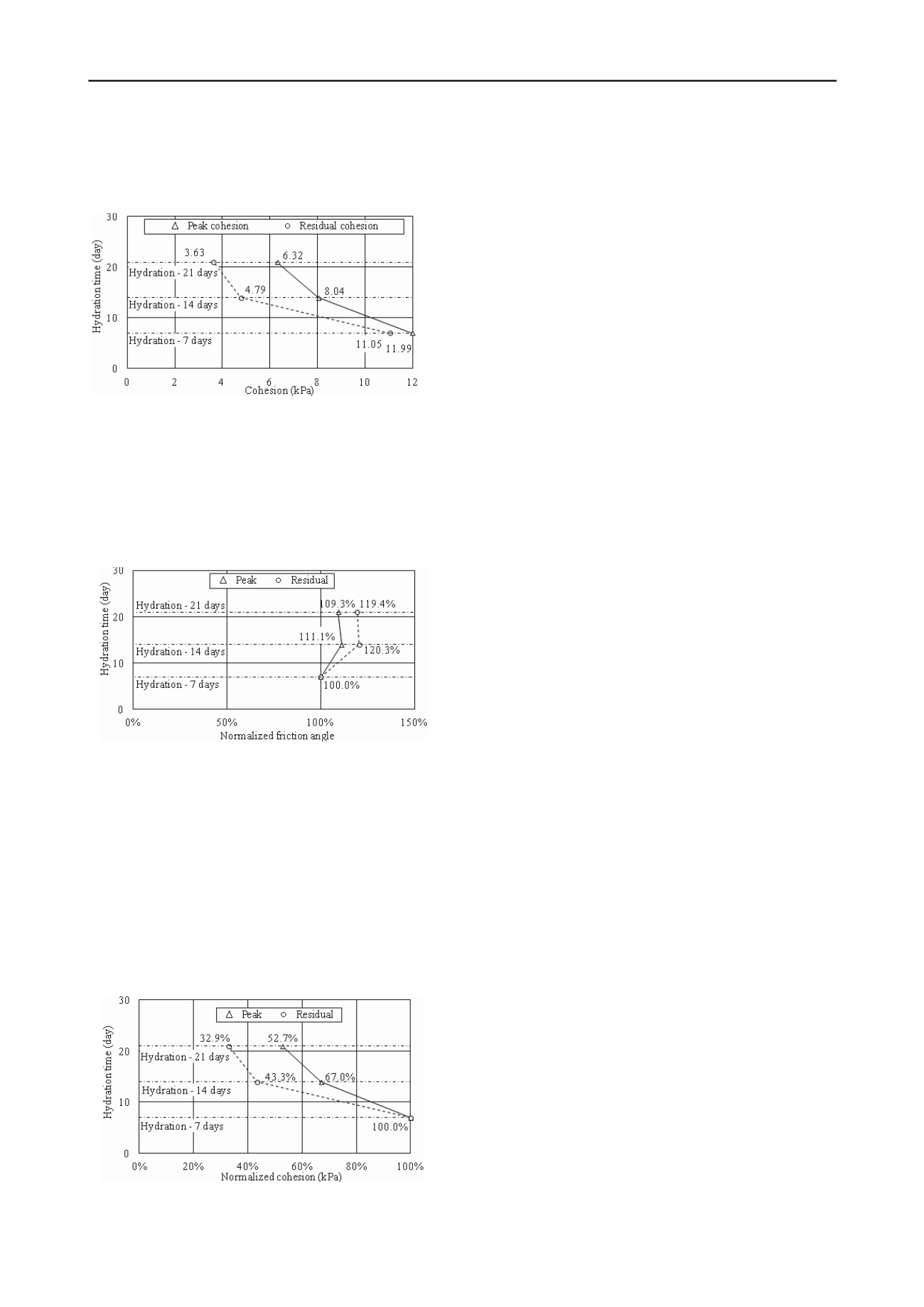

Friction angle and cohesion values were normalized and

expressed in percentages in relation to the parameter values

after seven days of hydration. It is evident that a 14-day

hydration causes peak friction angle to increase by around 10%,

while extended hydration time results in insignificant decrease

of the friction angle (Figure 7). The increase is higher with the

residual friction angle – by around 20% after 14 days of

hydration, while after that it decreases insignificantly.

With extended hydration time (from 7 to 14 days), the friction

angle initially increases, but further extension of hydration (to

more than 14 days) produces almost no change in the friction

angle value. Peak and residual friction angles change in line

with this pattern, but the extent is somewhat smaller for the

residual friction angle.

Knowing the process of swelling of bentonite is important from

the aspect of shear strength of bentonite and clay geosynthetic

barriers. Also, the displacement rate influences peak and

residual values of bentonite shear strength. Lower displacement

rate means a longer test duration overall, and consequently more

time for hydration/swelling in case of normal stress levels that

are smaller than the bentonite swelling pressure. Potential

continuation of the hydration process in the shearing stage will

depend on the stage of swelling that the specimen is in. If the

time required to finalize primary swelling has been reached, it

can be assumed that hydration of the specimen would end, and

that after this the specimen would enter the stage of secondary

compression

5

ACKNOWLEDGMENTS

Figure 7. Hydration time vs. normalized friction angle.

Cohesion values continuously decrease with the increase of

hydration time, and this is particularly evident with residual

cohesion, where this reduction is more obvious (Figure 8).

Specifically, the value of peak cohesion equals 67% of

normalized value (in comparison to 7-day hydration) after 14

days of hydration and 52.7% after 21 days of hydration; the

value of residual cohesion equals 43.3% of normalized value,

which is by 13.7% higher reduction in residual cohesion. After

21 days of hydration, the value of residual cohesion equals

32.9% of normalized value, which is by 9.8% less in

comparison with peak cohesion.

This paper was produced with financial support from the

Croatian Ministry of Science, Education and Sports, through a

project "Long-term performance of mineral barriers"; 195-

0831529-1847.

6

REFERENCES

Mitchell J. K. and Soga K. (2005): Fundamentals of Soil Behavior, John

Wiley and Sons, New York

Shackelford, C. D., Benson, C. H., Katsumi, T., Edil, T. B. and Lin, L.

(2000): Evaluating the hydraulic conductivity of GCLs permeated

with non-standard liquids, Geotextiles and Geomembranes, 18 (2–

4), 133–162.

Shackelford, C. D., Sevick, G. W. and Eykhol, G. R. (2010): Evaluating

the hydraulic conductivity of GCLs permeated with non-standard

liquids, Geotextiles and Geomembranes, 18, 133–162.

Zornberg, J. G. and McCartney, J. S. (2009): Chapter 8: Internal and

interface shear strength of geosynthetic clay liners, In: GCLs for

Waste Containment, Bouazza, A. & Bowders, J.J. (Ed), CRC Press.

Kovačević Zelić, B. (2000): Ispitivanje posmične čvrstoće bentonitnih

tepiha, Doktorska disertacija, RGN-fakultet, Zagreb.

Guyonnet, D., Touze Foltz, N., Norotte, V., Pothier, C., Didier, G.,

Gailhanou, H., Blanc, P. and Warmont, F. (2009): Performance-

based indicators for controlling geosynthetic clay liners in landfill

applications; Geotextiles and Geomembranes 27, 321–331.

Fox, P. J. (2010): Internal and interface shear strengths of geosynthetic

clay liners, 3rd Int. Symp. on GCLs, 15-19.9.2010, Germany,

Zanzinger, H., Koerner , R. M. & Touze-Foltz, N. (Eds.), 203-218.

Gilbert, R. B., Fernandez, F. F. and Horsfield, D. (1996): Shear strength

of a reinforced clay liner, Journsl of Geot. and Geoenv. Eng., 122,

259-266.

Bouazza, A. (2002): Geosynthetic Clay Liners, Geotextiles and

Geomembranes 20, Elsevier Science.

Figure 8. Hydration time vs. normalized cohesion.