213

Technical Committee 101 - Session I /

Comité technique 101 - Session I

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Tab.2 Initial physical parameters and stress states of samples before soaking

6

5

4

3

2

1

80

10 9 8.67

9

14

12.67

16.67

39.1

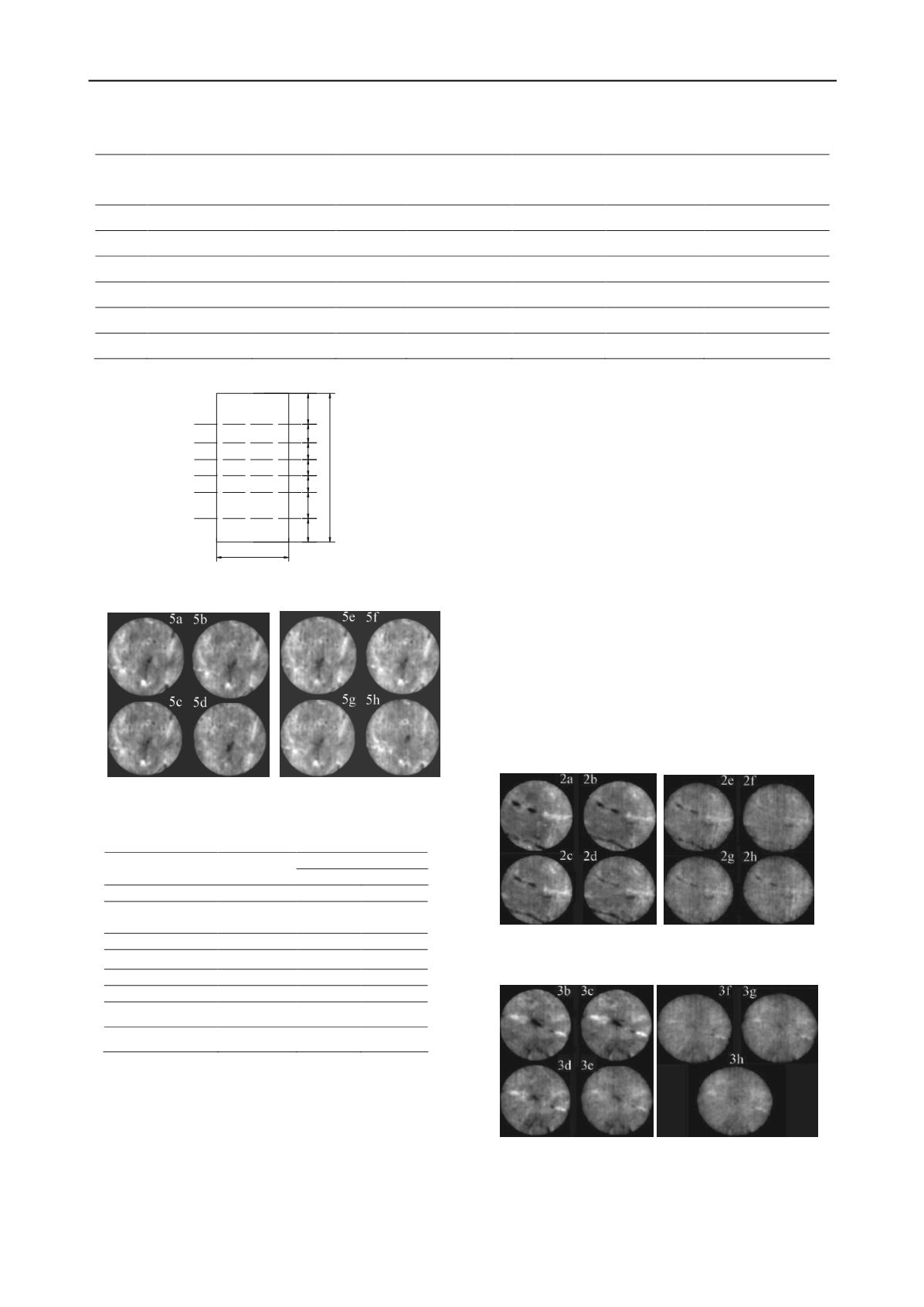

Figure 5. Scanning position (length unit: mm)

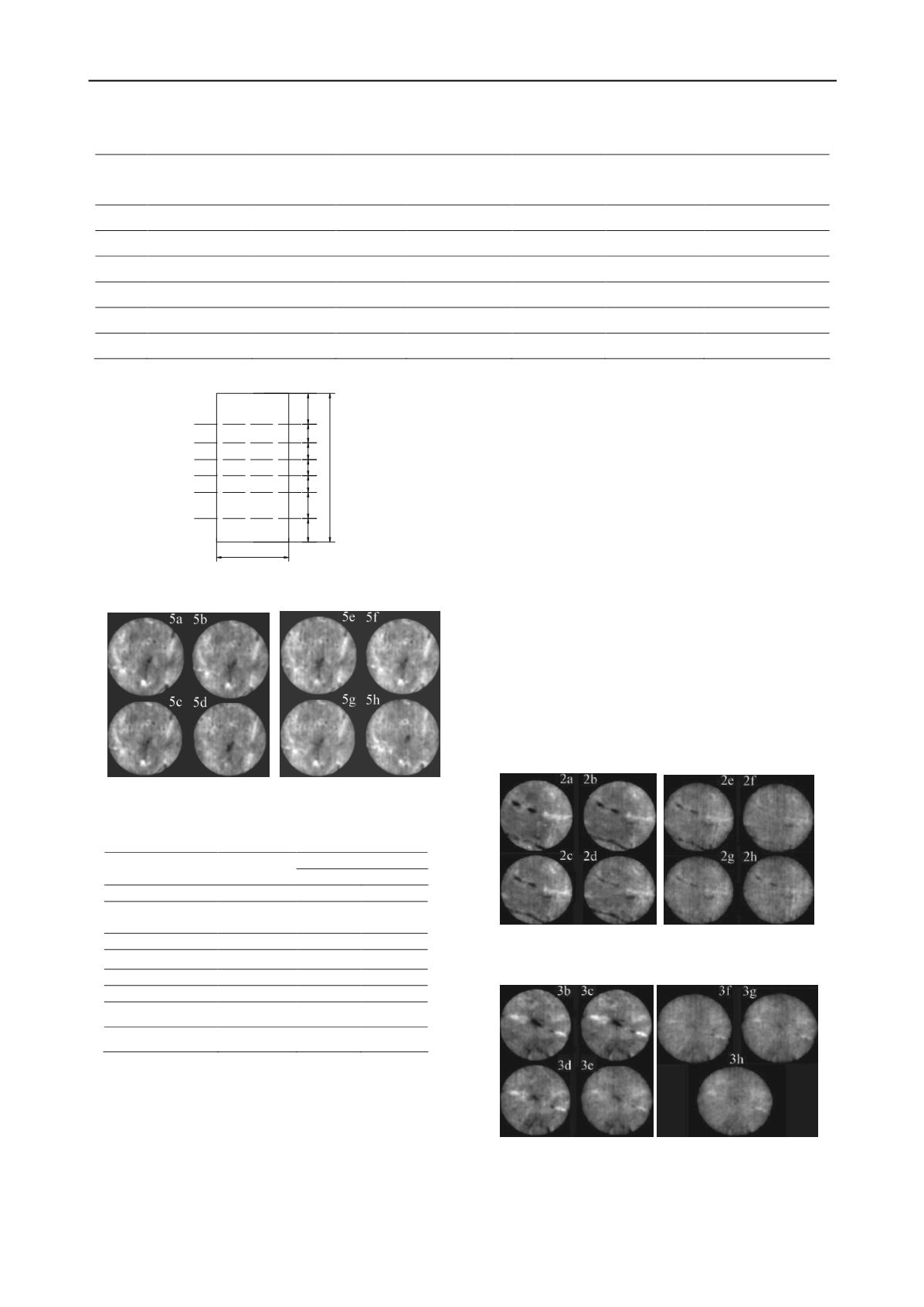

Figure 6 Scanning images of 5

th

section of sample 3

#

of Q

3

loess

during loading

Tab.3 CT data and stress state of sample 3# during loading

5

th

Section

Stress state

Scan

sequence

H

SD

Initial state

a

821.1

49.4

End of

consolidation

b

854.6

44.7

q = 25 kPa

c

856.5

44.7

q = 50 kPa

d

852.7

41.4

q = 75 kPa

e

854.1

42.6

q = 100 kPa

f

854.0

41.7

q = 150 kPa

g

887.0

45.9

q = 200 kPa

h

927.2

43.4

4 STRUCTURE EVOLUTION OF LOESS Q

3

Collapsibility is the most important feature of loess.

However, collapsibility depends on the meso-structure of loess.

In order to discover the characteristics of the meso-structure

evolution of loess, 10 groups of CT-triaxial tests including 49

samples of Q

3

loess were conducted. A total of 847 CT images

and a number of CT data were obtained (Zhu, 2007; Fang,

2008; Li, 2010).

4.1 The structure evolution of Q

3

loess during loading and

collapsing

Six tests of intact Q

3

loess were conducted. The size of samples

was 39.1mm in diameter and 80mm in height. The initial

conditions and test parameters of the samples are shown in table

2. Each sample was scanned 6 sections (Figure 5), and each

section was scanned from 6 to 8 times. The scanning pictures

were marked as a, b, c, d, e, f, g and h corresponding to a

section in successive scanning (Zhu, 2008a). A total of 273 CT

images were obtained.

Figure 6 shows the Scanning images of 5

th

section of sample

3

#

of Q

3

loess during loading. The scanning pictures were

marked as a, b, c, d, e, f, g and h corresponding to the initial

state, the end of consolidation, and deviator stress ( q ) equal to

25

,

50

,

75

,

100

,

150 and 200 kPa of the 5

th

section (

Table

3)

. H and SD in table 3 are the mean value and the standard

deviation of CT data of the 5

th

section.

It is clear from Figure 6 and

Table 3

that consolidation has

significant effect on the meso-structure of sample, and there is

no evident change in the meso-structure of sample 3

#

before

deviator stress less than 150 kPa. In addition, the defect region

(black part in Figure 6) not vanishes completely at the end of

loading.

Figure 7 Scanning images during triaxial collapse of

2nd section of sample 4# of intact Q3 loess

Fig.8 Scanning images during triaxial collapse of

3rd section of sample 4# of intact Q3 loess

No.of

sample

Initial dry density

g / cm

3

Initial water

content /% Void ratio

Net cell pressure

3

- )

a

u

(

/ kPa

Matric suction

s / kPa

Deviator stress

q / kPa

Water pressure

during soak / kPa

1

1.31

11.0

1.08

100

150

0

4

2

1.31

11.0

1.08

200

150

0

12

3

1.32

11.0

1.04

100

150

200

14

4

1.32

11.0

1.05

100

250

0

12

5

1.31

11.0

1.06

100

150

100

14

6

1.30

11.0

1.08

100

150

250

14