210

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

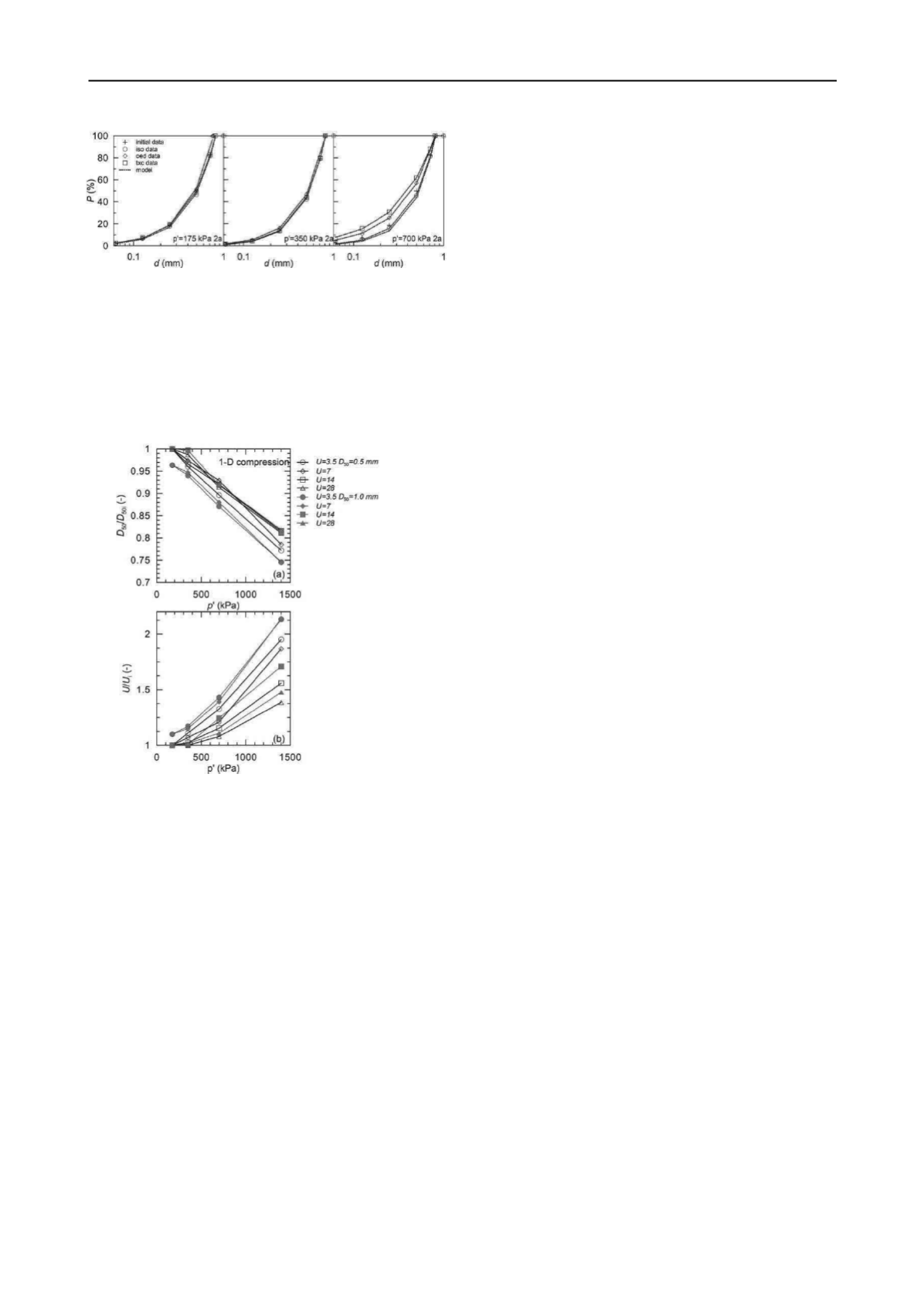

Figure 10. Grain size distribution evolution with

U

= 3.5 and

d

50

= 0.50

mm.

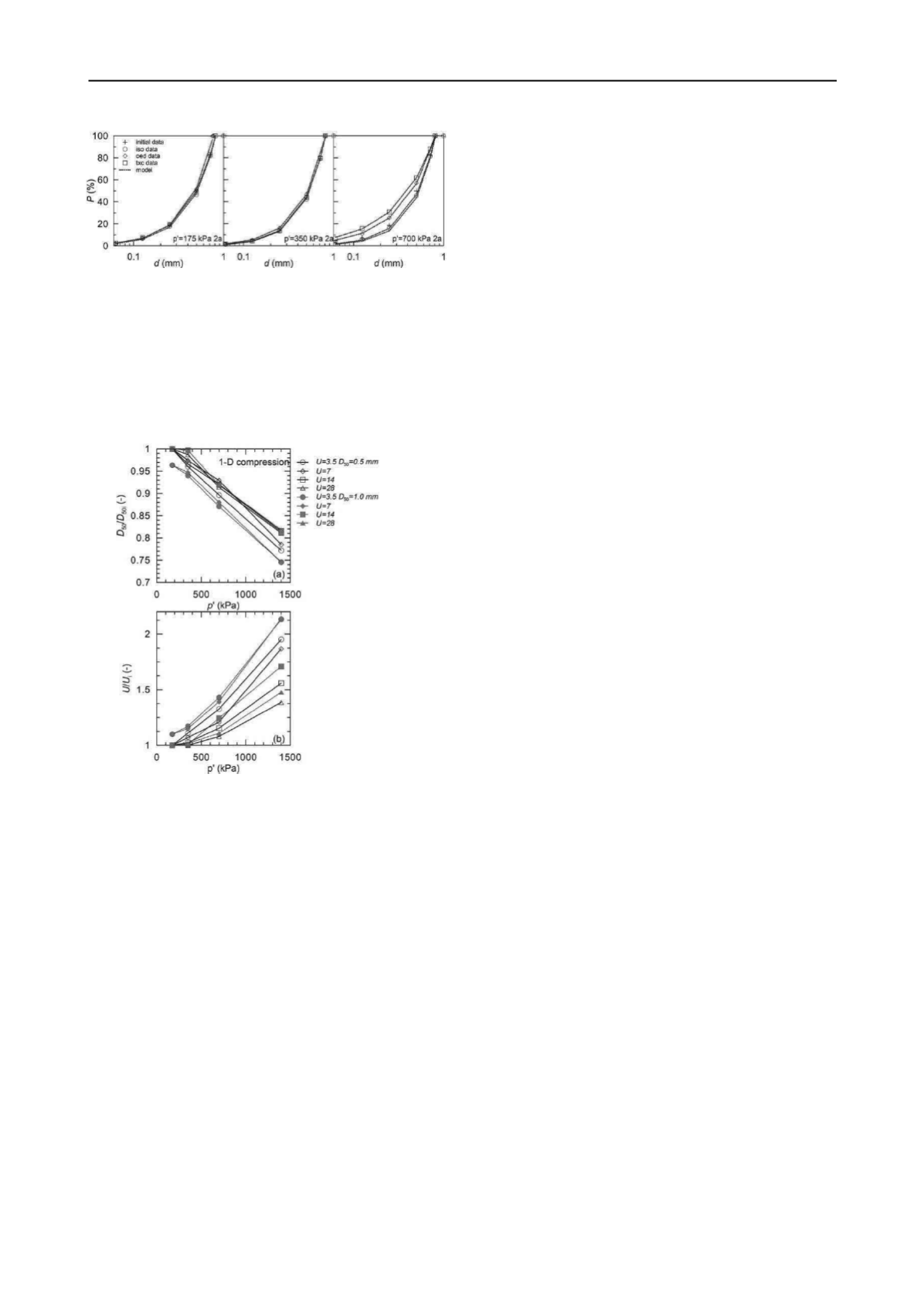

Grain crushing has been quantified, as a first approximation,

using the ratios between

d

50

/

d

50i

and

U

/

U

i

, where

d

50i

and

U

i

represent respectively the initial mean diameter and coefficient

of uniformity. Figure 11 (a) and (b) show the evolution for the

ratios

d

50

/

d

50i

and

U

/

U

i

after 1-D compression for all of the

initial GSDs tested, as a function of maximum mean effective

stress

p

'.

Figure 11. Evolution of ratios: (a)

d

50

/

d

50i

and (b)

U

/

U

i

with mean

effective stress applied in 1D-compression.

The reduction of

d

50

/

d

50i

with increasing

p’

is more pronounced

for samples with lower initial coefficient of uniformity (

U

i

=

3.5) and higher mean diameter (

d

50i

= 1 mm). Likewise, as the

initial

U

decreases, the ratio

U

/

U

i

increases by a factor greater

than 2 for the poorly graded samples with the greater d

50i

. The

ratio

U

/

U

i

is consistently higher for higher initial mean diameter

(

d

50i

= 1 mm) for all the GSDs tested, which is probably due to

the lower coordination number of the particles. The stress acting

on the neighbour is higher for the same magnitude and direction

of stress applied, as the coordination number decreases, as

larger particles tend to be cushioned by surrounding smaller

particles. This leads to higher coordination numbers and makes

the larger particles more resistant to crushing. Smaller particles,

with smaller coordination numbers, are more likely to be

crushed in the fragmentation process so that the cushioning

effect for larger particles is more relevant than the lower particle

strength with increasing particle size.

3 CONCLUSIONS

An extensive laboratory investigation has been conducted on an

artificial granular, expanded clay pellets LECA, composed of

grains that break at relatively low stresses. These lightweight

expanded clay aggregates are used in road construction,

tunnelling, structural backfill against foundations, retaining

walls and bridge abutments, because of their low unit weight

and good drainage properties. In many practical cases, the stress

levels to which the material is subjected are comparable to those

explored in the present experimental investigation.

The final grain size distribution measured after loading is

rotated upwards and translated leftwards (on a standard particle

size distribution plot) for all tested samples. The percentage of

finer particles increases with increasing mean effective stress

and stress-path obliquity. The grain size distributions can be

described satisfactorily using simple equations derived from a

fractal evolution of grading. Breakage has been quantified as a

first approximation through the evolution of non-dimensional

ratios of mean diameter and coefficient of uniformity. Poorly

graded samples show more pronounced decrease in mean

diameter and increase of uniformity with higher stress applied.

Further investigations will be undertaken to reproduce the

observed behaviour through a constitutive model to account for

breakage and its effects on mechanical behaviour.

ACKNOWLEDGEMENTS

The authors are grateful to Ralf Herzog (Institute for

Geotechnical Engineering) and Gabriele Peschke (Institute for

Building Materials), ETH Zurich, for their technical support.

REFERENCES

Casini, F. and Viggiani, G.M.B. (2011). Experimental investigation of

the evolution of grading of an artificial material with crushable grains

under different loading conditions.

Proc. Int. Symp on: Deformation

Characteristics of Geomaterials

, IS-Seoul 2011, 957-964.

Casini F., Viggiani G.M.B. and Springman S.M. (2013). Breakage of an

artificial crushable material under loading.

Granular Matter

(submitted).

Cho G., Dodds J. and Santamarina J. (2006). Particle Shape Effects on

Packing Density, Stiffness, and Strength: Natural and Crushed Sands.

J.

Geotech. Geoenviron. Eng.

, 132(5), 591

–

602.

Hardin, B.O. 1985. Crushing of soil particles.

Journal of Geotechnical

Engineering

, ASCE 111(10), 1177

–

1192.

Imre B., Laue, J. and Springman, S.M. (2010). Fractal fragmentation of

rocks within sturzstroms: insight derived from physical experiments

within the ETH Geotechnical Drum Centrifuge.

Granular Matter

12(3):

267-285. DOI: 10.1007/s10035-009-0163-1.

Imre B., Wildhaber, B. and Springman, S.M. (2011). A Physical

Analogue Material to Simulate Sturzstroms.

IJPMG

. 11(2): 69

–

86.

doi:10.1680/ijpmg.2011.11.2.69

Leu J., Low B. and Zimmermann (2011). Effects of grain size

distribution and confining stress on the mechanical behaviour of an

artificial crushable material

Project thesis

, ETH Zurich, Switzerland.

McDowell, G.R. & Bolton, M.D. (1998). On the micromechanics of

crushable aggregates.

Géotechnique

40(5): 667

–

679.

Miura, K., Maeda, K., Furukawa, M. and Toki, S. (1997). Physical

characteristics of sands with different primary properties.

Soils and

Foundations

37(3): 53-64.

Peck, A. (2008).

Beginning GIMP: From Novice to Professional

,

Second Edition. Apress, 548 pp.

Wanninger F. and Zwicker P. (2010). Effects of grain crushing on

compressibility of an artificial material.

Semester Thesis

, ETH Zurich,

Switzerland.

Sammis, C.G., King, G. and Biegel, R. (1987). The kinematics of gouge

deformations.

Pure Appl. Geophys.

125, 777

–

812.

Tsoungui, O., Vallet, D. and Charmet, J.C. (1999). Numerical model of

crushing of grains inside two-dimensional granular materials.

Powder

Technology

, 105(1-3), 190-198.

Turcotte, D.L. 1986. Fractals and fragmentation.

J. of Geophysical

Research

91(B2): 1921

–

1926.