220

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

437.0%, plastic limit 52.86%, specific surface area 700 m2/g

and ion exchange capacity 88.63+/-6.51 meq/100g. The

influence of swelling and water content of bentonite samples on

the measured values of total shear strength and shear strength

parameters was observed using the direct shear device. In a

series of tests, under conditions of varying effective stress,

hydration times were changed depending on the results of

oedometric tests in order to simulate different levels of

bentonite swelling. Swelling behavior of bentonite was defined

through long-term oedometer tests with varying effective stress.

In order to prevent the change in chemical and mineralogical

composition of bentonite, demineralised water was used as the

test fluid. Shear displacement rate was 1 mm/min. This

displacement rate enables relatively short shear stage in relation

to previously finished hydration stage, that is, the reduced

impact of additional hydration and creep during shear stage on

the test results.

2

OEDOMETER SWELL TEST

Bentonite swelling tests were performed using standard

oedometer cells of 74 mm in diameter. The placement

procedure was relatively simple i.e. pouring of granular

bentonite into the oedometric cell was performed without the

application of external loading. The initial water content (as-

received) of granules was approximately 12%. Identical

amounts of bentonite were used for all specimens, making sure

that the bentonite is not compacted, but only slightly flattened.

After installation, the specimens were loaded to normal stress

levels of 50, 100 and 200 kPa. The next step was to add

demineralised water into the cell, leaving the specimens to swell

under applied normal stress levels for the next 276 days. At the

end of experiments, specimens were taken out of the device, and

final moisture content was determined.

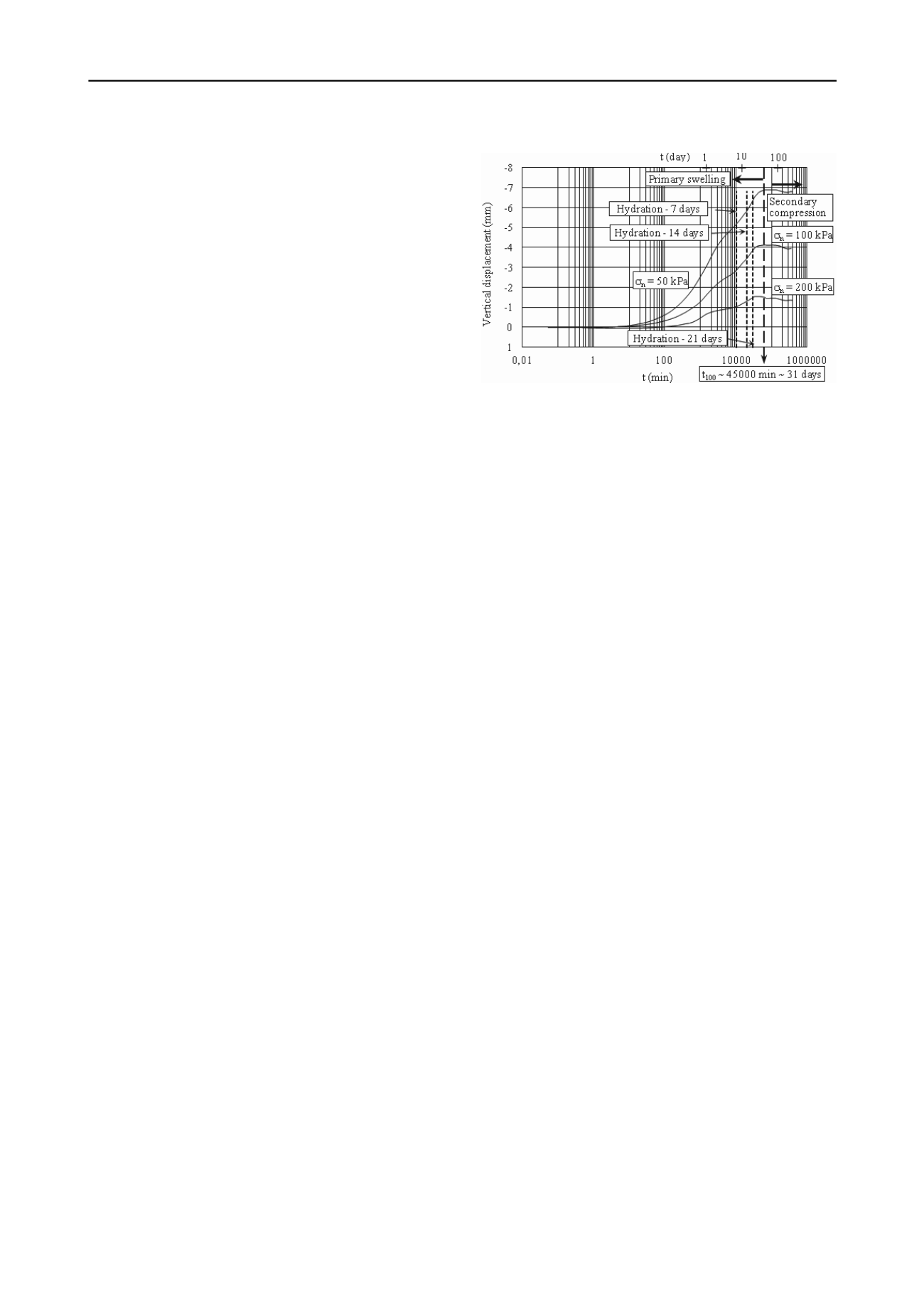

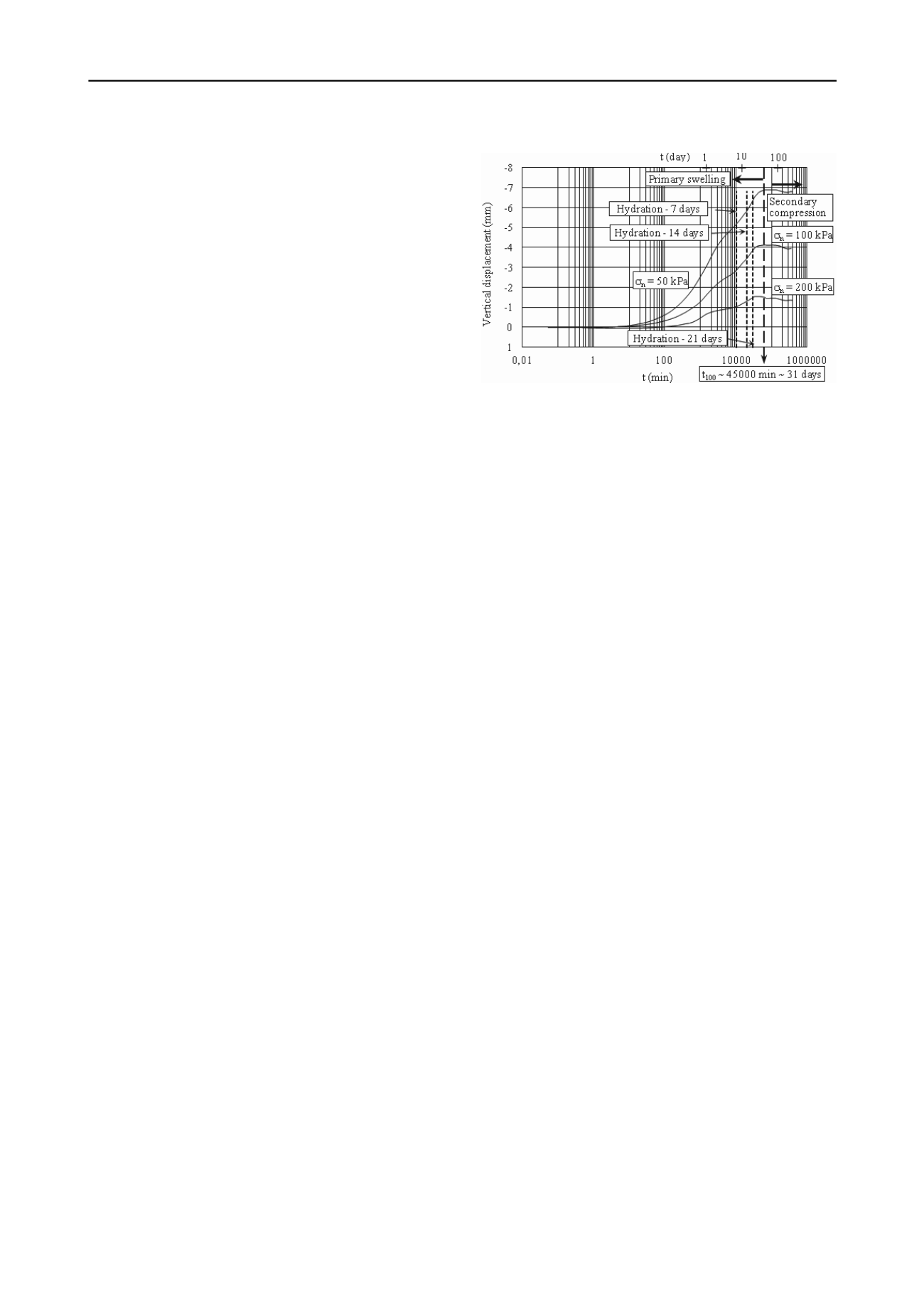

Test results showed the highest level of swelling and

relative vertical deformation for those specimens that were

under the lowest levels of normal stress. Therefore, the intensity

of swelling decreased as normal stress level increased. It is

evident on the basis of the swelling curves that relative vertical

deformation (swelling) of specimens after the period of 276

days was 65.80% (6.787 mm) under normal stress of 50 kPa;

38.54% (3.945 mm) under normal stress of 100 kPa and 13.93%

(1.339 mm) under normal stress of 200 kPa.

The analysis of time required for the primary swelling stage

indicates that these times were identical for all normal stress

levels (Figure 1). In this particular case, the time for completion

of the primary swelling was approximately 31 days, looking at

all three series.

On the basis of analysis of vertical deformation

development for these specimens upon completion of the

primary swelling stage, it is evident that in the period which

remained the stage of secondary compression started. Following

conclusions were drawn by observing vertical deformations

over the remaining period of 245 days during which there was

secondary compression of the specimens:

• with specimen subjected to normal stress intensity of 50

kPa, there was compression by 0.092 mm, resulting in vertical

deformation of 0.54%;

• with specimen subjected to normal stress intensity of 100

kPa, there was compression by 0.196 mm, resulting in vertical

deformation of 1.36%;

• with specimen subjected to normal stress intensity of 200

kPa, there was compression by 0.203 mm, resulting in vertical

deformation of 1.82%.

Figure 1. Bentonite swell tests.

Therefore, same as with the primary swelling, the rate of

vertical deformation in the stage of secondary compression and

how it develops with time also depends on normal stress levels,

but in this case the intensity of secondary compression increases

with the increase of normal stress level.

The specimens were subjected to secondary compression

over a long period of time, so it is assumed that the impact of

changing temperature in the laboratory on the vertical

deformation curves is possible during the period of secondary

compression. A combination of very low vertical deformations

and variable temperatures in the laboratory during measurement

may lead to a change in the rate of vertical deformation

increment during secondary compression. Some changes in

temperature in the laboratory were expected, and it is assumed

that they affect measuring sensors used in this test.

3

DIRECT SHEAR TEST

3.1

Laboratory testing program

Clay geosynthetic barriers are composite materials. Considering

the specific form of clay geosynthetic barriers, their shear

strength is mainly tested using modified direct shear devices.

This test was aimed at quantifying the performance of bentonite

clay component within the clay geosynthetic barrier. It was

conducted on a sample of granular bentonite, not including the

geosynthetic component. The shear strength tests on some

unreinforced and particularly on reinforced clay geosynthetic

barriers indicate that special attention is required relating to the

size of specimen. However, the specimen size is not crucial

when testing the shear strength of bentonites. Therefore, a

standard direct shear device with box dimensions of 60×60 mm

was used in this study.

Previous studies of the shear strength of bentonite indicate

that the key influence on its behavior comes from the property

of swelling i.e. moisture content in the specimen. In order to

establish the influence of bentonite swelling on its shear

strength, specimens were tested in three series under normal

stress of 50, 100 and 200 kPa, with varying hydration times (7,

14 and 21 days).

The specimen placement procedure consisted of pouring

bentonite into the shear box. The as-received water content level

in granules was approximately 12%. The same amount of

granulated bentonite was always used, making sure that the

bentonite is not compacted, but only slightly flattened. The

described procedure ensured approximately identical initial

values for thickness, dry mass and dry density of all specimens

(their thickness was approximately 8 mm). This kind of

procedure was believed to provide a representative simulation

for the conditions under which bentonite is used as part of clay

geosynthetic barriers. After the placement, normal stress

loading was applied on the specimens immediately followed by

the initiation of hydration procedure. After finished hydration